Fossil-based plastics are derived from non-renewable petroleum resources, contributing significantly to environmental pollution and carbon emissions. Bio-based plastics originate from renewable biomass sources such as corn, sugarcane, or cellulose, offering a more sustainable alternative with lower ecological impact. The shift from fossil-based to bio-based content in plastics is crucial for reducing dependency on finite fossil fuels and enhancing biodegradability.

Table of Comparison

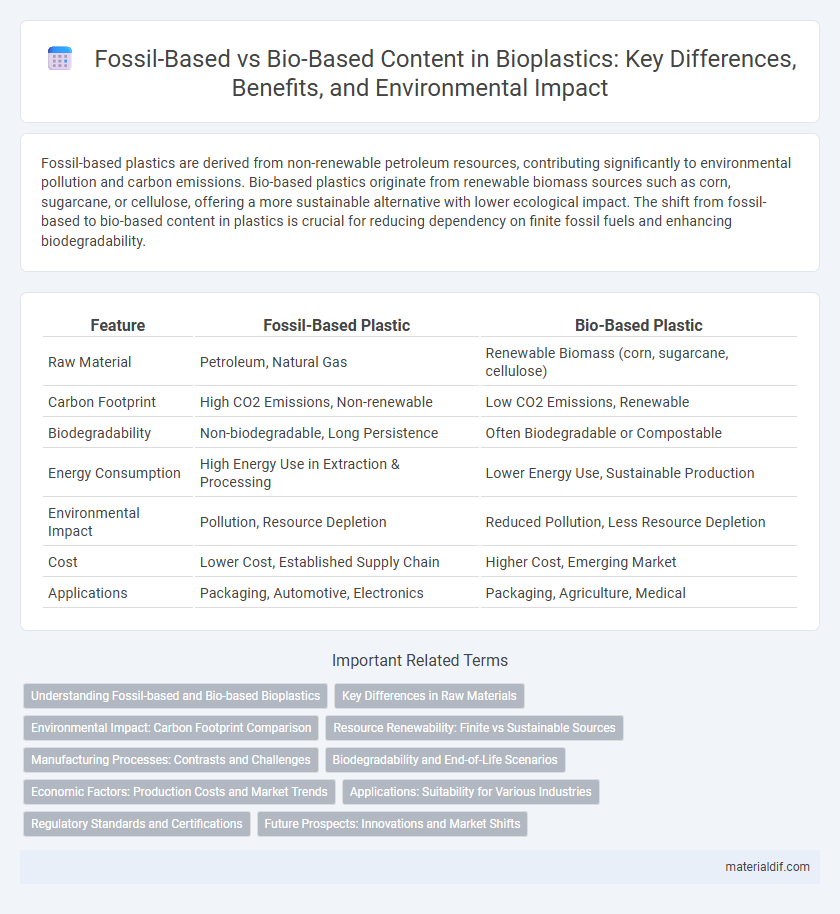

| Feature | Fossil-Based Plastic | Bio-Based Plastic |

|---|---|---|

| Raw Material | Petroleum, Natural Gas | Renewable Biomass (corn, sugarcane, cellulose) |

| Carbon Footprint | High CO2 Emissions, Non-renewable | Low CO2 Emissions, Renewable |

| Biodegradability | Non-biodegradable, Long Persistence | Often Biodegradable or Compostable |

| Energy Consumption | High Energy Use in Extraction & Processing | Lower Energy Use, Sustainable Production |

| Environmental Impact | Pollution, Resource Depletion | Reduced Pollution, Less Resource Depletion |

| Cost | Lower Cost, Established Supply Chain | Higher Cost, Emerging Market |

| Applications | Packaging, Automotive, Electronics | Packaging, Agriculture, Medical |

Understanding Fossil-based and Bio-based Bioplastics

Fossil-based bioplastics are derived primarily from petroleum or natural gas, containing carbon structures sourced from non-renewable fossil fuels, whereas bio-based bioplastics utilize renewable biomass such as corn, sugarcane, or cellulose as raw materials. The key distinction lies in the carbon origin: fossil-based bioplastics contribute to carbon emissions linked to fossil carbon cycles, while bio-based bioplastics promote carbon neutrality by cycling atmospheric CO2 through plant growth and biodegradation. Understanding the sourcing and lifecycle impact of these bioplastics is essential for assessing their environmental benefits and determining sustainable applications.

Key Differences in Raw Materials

Fossil-based plastics are primarily derived from non-renewable petroleum and natural gas, making their raw materials finite and environmentally taxing. Bio-based plastics utilize renewable biomass sources such as corn, sugarcane, or cellulose, which contribute to lower carbon footprints and enhanced sustainability. The key difference lies in the origin of raw materials: fossil-based plastics rely on fossil fuels, while bio-based alternatives harness agricultural and biological feedstocks.

Environmental Impact: Carbon Footprint Comparison

Bio-based bioplastics generally exhibit a significantly lower carbon footprint compared to fossil-based plastics due to their renewable feedstocks and carbon sequestration during biomass growth. Fossil-based plastics release substantial amounts of greenhouse gases throughout extraction, processing, and disposal, contributing heavily to atmospheric CO2 levels. Lifecycle assessments reveal that replacing conventional plastics with bio-based alternatives can reduce carbon emissions by up to 70%, fostering sustainable packaging and mitigating climate change.

Resource Renewability: Finite vs Sustainable Sources

Fossil-based bioplastics rely on finite resources such as petroleum and natural gas, contributing to resource depletion and environmental concerns. Bio-based bioplastics derive from renewable biomass like corn, sugarcane, and cellulose, promoting sustainable resource cycles and reducing dependency on non-renewable fossil fuels. The shift to bio-based content enhances circular economy efforts by utilizing sustainable agricultural feedstocks and minimizing carbon footprint.

Manufacturing Processes: Contrasts and Challenges

Fossil-based plastics rely on petrochemical refining, involving energy-intensive extraction and polymerization of crude oil derivatives, while bio-based plastics utilize renewable biomass such as corn, sugarcane, or cellulose through fermentation, enzymatic conversion, or direct polymerization. Manufacturing bio-based plastics faces challenges in feedstock variability, scalability, and competition with food resources, in contrast to the well-established, consistent, and high-throughput fossil fuel processes. The integration of advanced biorefinery technologies aims to optimize yield and reduce environmental impact, yet cost-efficiency and infrastructure adaptation remain significant barriers compared to fossil-based plastic production.

Biodegradability and End-of-Life Scenarios

Bio-based bioplastics primarily derive from renewable biomass sources such as corn, sugarcane, or cellulose, offering enhanced biodegradability compared to fossil-based plastics that rely on petrochemical feedstocks. Biodegradability in bio-based plastics varies widely, with certain types like polylactic acid (PLA) and polyhydroxyalkanoates (PHA) decomposing more effectively under industrial composting conditions than conventional plastics. End-of-life scenarios for bio-based bioplastics favor composting and anaerobic digestion, reducing environmental impact through organic recycling pathways, whereas fossil-based plastics predominantly end in landfills or recycling streams with limited biodegradation potential.

Economic Factors: Production Costs and Market Trends

Bio-based bioplastics generally incur higher production costs than fossil-based counterparts due to expensive raw materials and less mature manufacturing technologies. Market trends show growing consumer demand and regulatory incentives favor bio-based bioplastics, driving investments despite cost challenges. Economies of scale and advancements in bio-refineries are expected to reduce production costs, enhancing the competitive position of bio-based plastics in global markets.

Applications: Suitability for Various Industries

Bioplastics with bio-based content are increasingly preferred in industries such as packaging, agriculture, and consumer goods due to their renewable origins and reduced carbon footprint. Fossil-based plastics remain dominant in sectors requiring high-performance materials, like automotive and aerospace, where durability and heat resistance are critical. Emerging hybrid materials combining fossil-based and bio-based components offer tailored solutions, enhancing suitability across diverse industrial applications.

Regulatory Standards and Certifications

Fossil-based plastics are predominantly regulated under traditional polymer production standards, while bio-based plastics must comply with additional certifications such as ASTM D6866 for biobased content and EN 13432 for compostability. Regulatory frameworks like the EU's Renewable Energy Directive (RED II) emphasize biobased carbon measurement to incentivize sustainable plastic production. Certification programs including TUV Austria OK Biobased and USDA BioPreferred ensure bio-based plastics meet environmental claims, fostering transparency and consumer trust in sustainable sourcing.

Future Prospects: Innovations and Market Shifts

Bio-based bioplastics demonstrate significant growth potential due to increasing consumer demand and regulatory pressure to reduce fossil-based plastic dependency. Innovations in feedstock utilization, such as waste biomass and algae, enhance sustainability and cost-efficiency, positioning bio-based polymers as competitive alternatives. Market shifts driven by circular economy principles and carbon neutrality goals are accelerating investment and adoption in the bioplastics sector.

Fossil-based vs Bio-based content Infographic

materialdif.com

materialdif.com