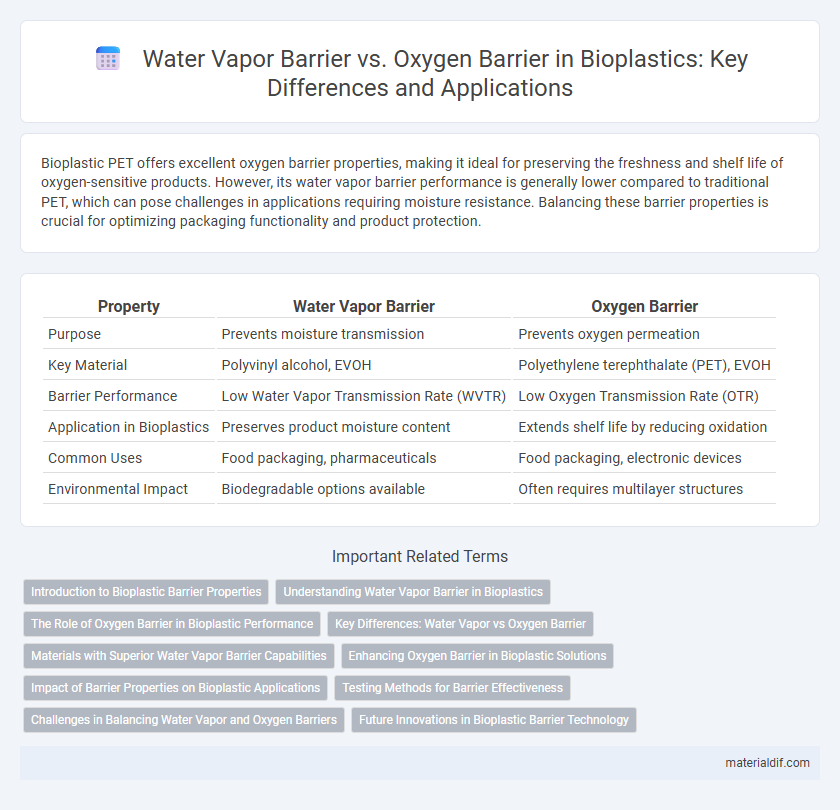

Bioplastic PET offers excellent oxygen barrier properties, making it ideal for preserving the freshness and shelf life of oxygen-sensitive products. However, its water vapor barrier performance is generally lower compared to traditional PET, which can pose challenges in applications requiring moisture resistance. Balancing these barrier properties is crucial for optimizing packaging functionality and product protection.

Table of Comparison

| Property | Water Vapor Barrier | Oxygen Barrier |

|---|---|---|

| Purpose | Prevents moisture transmission | Prevents oxygen permeation |

| Key Material | Polyvinyl alcohol, EVOH | Polyethylene terephthalate (PET), EVOH |

| Barrier Performance | Low Water Vapor Transmission Rate (WVTR) | Low Oxygen Transmission Rate (OTR) |

| Application in Bioplastics | Preserves product moisture content | Extends shelf life by reducing oxidation |

| Common Uses | Food packaging, pharmaceuticals | Food packaging, electronic devices |

| Environmental Impact | Biodegradable options available | Often requires multilayer structures |

Introduction to Bioplastic Barrier Properties

Bioplastic barrier properties are crucial in determining their effectiveness for packaging applications, with water vapor barrier and oxygen barrier being two key metrics. Water vapor barrier refers to the material's ability to prevent moisture transmission, which is essential for preserving product freshness and preventing spoilage. Oxygen barrier measures the resistance against oxygen permeation, important for extending shelf life by reducing oxidation and microbial growth.

Understanding Water Vapor Barrier in Bioplastics

Water vapor barrier properties in bioplastics are crucial for preventing moisture transmission, which can degrade sensitive products and reduce shelf life. Polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHA) exhibit variable water vapor permeability depending on their crystallinity and molecular structure. Optimizing the water vapor barrier in bioplastics involves enhancing polymer density or incorporating nanofillers such as clay or cellulose nanocrystals to improve moisture resistance without compromising biodegradability.

The Role of Oxygen Barrier in Bioplastic Performance

The oxygen barrier property plays a crucial role in bioplastic performance by preventing oxidation and maintaining product freshness, especially in food packaging applications. Effective oxygen barriers in bioplastics reduce permeability, extending shelf life and preserving the sensory and nutritional quality of packaged goods. While water vapor barriers manage moisture transfer, oxygen barriers specifically inhibit the intrusion of oxygen, which is key to preventing spoilage and degradation in biodegradable packaging materials.

Key Differences: Water Vapor vs Oxygen Barrier

Water vapor barriers in bioplastics are designed to prevent moisture transmission, essential for preserving product freshness and preventing spoilage in high-humidity environments. Oxygen barriers focus on limiting oxygen permeability to protect sensitive contents from oxidation, thereby extending shelf life and maintaining quality. While both barriers enhance packaging performance, their effectiveness depends on specific application needs, with water vapor barriers crucial for moisture-sensitive products and oxygen barriers critical for oxidation-prone items.

Materials with Superior Water Vapor Barrier Capabilities

Materials such as polyvinylidene chloride (PVDC) and ethylene vinyl alcohol (EVOH) exhibit superior water vapor barrier properties crucial for preserving product freshness and extending shelf life in bioplastic packaging. Compared to oxygen barriers, water vapor barriers prevent moisture infiltration more effectively, which is essential for products sensitive to humidity and condensation. Innovative bioplastics, including multilayer films combining cellulose and chitosan, demonstrate enhanced water vapor resistance while maintaining biodegradability and environmental sustainability.

Enhancing Oxygen Barrier in Bioplastic Solutions

Enhancing the oxygen barrier in bioplastic solutions involves integrating advanced nanocomposites such as layered silicates or graphene oxide, which significantly reduce oxygen permeability while maintaining biodegradability. Optimized multilayer coatings combining chitosan and polylactic acid improve oxygen resistance, crucial for food packaging applications requiring extended shelf life. Water vapor barrier properties can be tailored independently by incorporating hydrophobic polymers like polyhydroxyalkanoates, allowing precise control over moisture and gas transmission rates.

Impact of Barrier Properties on Bioplastic Applications

Water vapor barrier properties in bioplastics significantly influence their suitability for packaging perishable food by preventing moisture transfer and extending shelf life. Oxygen barrier performance is critical for protecting oxygen-sensitive products, such as pharmaceuticals and fresh produce, by reducing oxidative degradation. Optimizing both barrier properties enhances bioplastic functionality, making them competitive alternatives to traditional plastics in food and medical applications.

Testing Methods for Barrier Effectiveness

Water vapor barrier and oxygen barrier properties of bioplastics are evaluated using standardized testing methods like ASTM E96 for water vapor transmission rate (WVTR) and ASTM D3985 for oxygen transmission rate (OTR). These tests measure the permeability of bioplastic films to water vapor and oxygen under controlled conditions of temperature and humidity, providing critical data for packaging applications. Precise evaluation of barrier effectiveness ensures bioplastics meet performance requirements for extending product shelf life and maintaining quality.

Challenges in Balancing Water Vapor and Oxygen Barriers

Balancing water vapor and oxygen barriers in bioplastics presents significant challenges due to the inherently different molecular interactions required to block moisture versus gases. Materials that effectively prevent oxygen permeation often allow higher water vapor transmission, compromising shelf life and product integrity. Innovations in multilayer bioplastic structures and hybrid coatings aim to optimize these barriers, yet maintaining both functionalities without sacrificing biodegradability remains a critical hurdle.

Future Innovations in Bioplastic Barrier Technology

Future innovations in bioplastic barrier technology are driven by advancements in nanocomposites and bio-based coatings that enhance both water vapor and oxygen barrier properties, crucial for extending shelf life in food packaging. Research focuses on integrating cellulose nanofibers and chitosan to create multifunctional barriers with improved mechanical strength and biodegradability. These developments aim to balance performance with environmental sustainability, positioning bioplastics as competitive alternatives to conventional petrochemical-based materials.

Water Vapor Barrier vs Oxygen Barrier Infographic

materialdif.com

materialdif.com