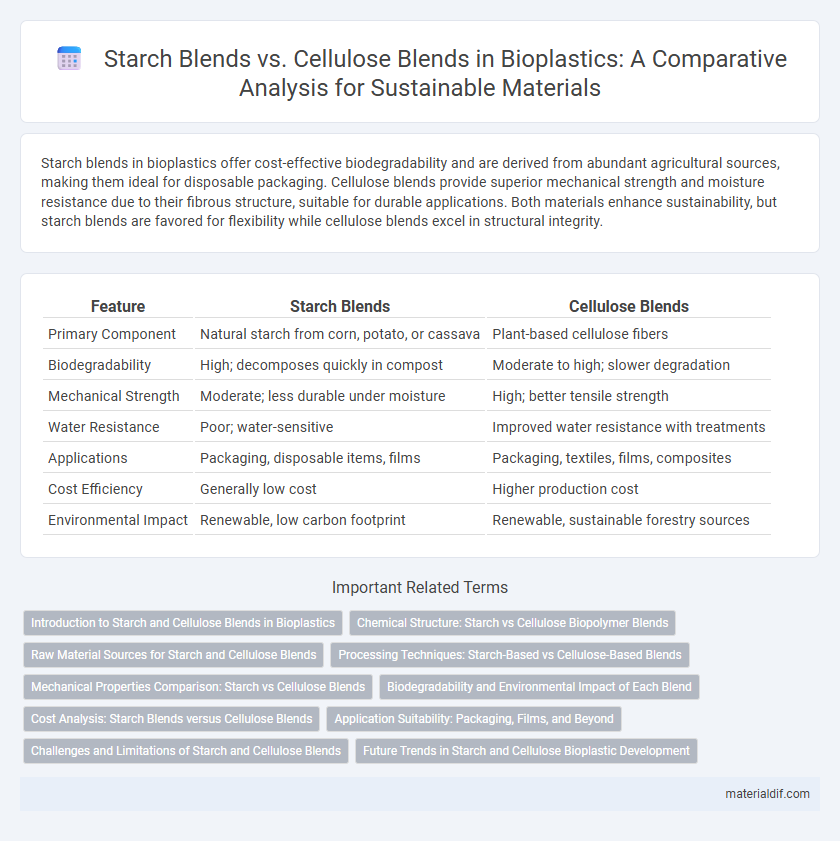

Starch blends in bioplastics offer cost-effective biodegradability and are derived from abundant agricultural sources, making them ideal for disposable packaging. Cellulose blends provide superior mechanical strength and moisture resistance due to their fibrous structure, suitable for durable applications. Both materials enhance sustainability, but starch blends are favored for flexibility while cellulose blends excel in structural integrity.

Table of Comparison

| Feature | Starch Blends | Cellulose Blends |

|---|---|---|

| Primary Component | Natural starch from corn, potato, or cassava | Plant-based cellulose fibers |

| Biodegradability | High; decomposes quickly in compost | Moderate to high; slower degradation |

| Mechanical Strength | Moderate; less durable under moisture | High; better tensile strength |

| Water Resistance | Poor; water-sensitive | Improved water resistance with treatments |

| Applications | Packaging, disposable items, films | Packaging, textiles, films, composites |

| Cost Efficiency | Generally low cost | Higher production cost |

| Environmental Impact | Renewable, low carbon footprint | Renewable, sustainable forestry sources |

Introduction to Starch and Cellulose Blends in Bioplastics

Starch blends in bioplastics offer biodegradable and cost-effective materials derived from renewable resources, providing good film-forming properties and suitability for packaging applications. Cellulose blends provide high mechanical strength and thermal stability, enhancing durability while maintaining biodegradability through natural polymer integration. Combining starch and cellulose enables tailored material performance by balancing flexibility, strength, and environmental impact for diverse bioplastic uses.

Chemical Structure: Starch vs Cellulose Biopolymer Blends

Starch blends consist of amylose and amylopectin polymers with a-(1-4) and a-(1-6) glycosidic bonds, resulting in branched and amorphous structures that enhance biodegradability and flexibility. Cellulose blends contain linear chains of b-(1-4) linked glucose units, forming crystalline regions that provide high tensile strength and thermal stability. The distinct chemical structures affect their compatibility with other polymers, processing behavior, and end-use properties in bioplastic applications.

Raw Material Sources for Starch and Cellulose Blends

Starch blends primarily source raw materials from corn, potatoes, and tapioca, utilizing abundant and renewable agricultural crops rich in polysaccharides. Cellulose blends derive raw materials from plant fibers including wood pulp, cotton, and agricultural residues, emphasizing lignocellulosic biomass with high cellulose content. Both starch and cellulose blends leverage bio-based feedstocks, but starch relies on edible crops while cellulose utilizes non-food plant matter, affecting sustainability and resource allocation.

Processing Techniques: Starch-Based vs Cellulose-Based Blends

Starch-based blends are processed primarily through extrusion and injection molding, benefiting from their thermoplastic properties and moisture sensitivity, which require precise temperature and humidity control. Cellulose-based blends demand solvent casting or chemical modification techniques, as cellulose's crystalline structure and limited thermoplasticity present processing challenges. Optimizing processing parameters for starch and cellulose blends enhances material performance and biodegradability in bioplastic applications.

Mechanical Properties Comparison: Starch vs Cellulose Blends

Starch blends exhibit lower tensile strength and elongation at break compared to cellulose blends, which demonstrate superior mechanical durability and flexibility due to their crystalline structure. Cellulose blends provide enhanced impact resistance and higher modulus values, making them more suitable for applications requiring structural integrity. Starch blends benefit from easier processing and biodegradability but often require plasticizers to improve their mechanical performance.

Biodegradability and Environmental Impact of Each Blend

Starch blends exhibit rapid biodegradability due to their simple polysaccharide structure, breaking down within weeks in composting environments, which significantly reduces landfill accumulation. Cellulose blends, characterized by a more crystalline structure, biodegrade at a slower rate but contribute to enhanced mechanical properties and stability, making them suitable for longer-term applications. Both blends offer environmentally friendly alternatives to petroleum-based plastics, with starch blends prioritizing faster decomposition and cellulose blends providing durability with moderate biodegradability.

Cost Analysis: Starch Blends versus Cellulose Blends

Starch blends generally offer a more cost-effective solution than cellulose blends due to lower raw material prices and simpler processing requirements. Cellulose blends, while providing superior mechanical properties and biodegradability, incur higher production costs related to extraction and chemical modification. Cost analysis reveals starch blends dominate in applications prioritizing economic efficiency, whereas cellulose blends are favored when performance justifies increased expenditure.

Application Suitability: Packaging, Films, and Beyond

Starch blends exhibit excellent biodegradability and are widely used in packaging and flexible film applications due to their moisture resistance and cost-effectiveness. Cellulose blends offer superior mechanical strength and clarity, making them ideal for high-performance films and sustainable packaging solutions requiring robust barrier properties. Both blends extend their use beyond packaging into agricultural mulch films and biodegradable bags, catering to diverse eco-friendly product demands.

Challenges and Limitations of Starch and Cellulose Blends

Starch blends face challenges such as poor water resistance and limited mechanical strength, restricting their applications in moisture-prone environments. Cellulose blends tend to have better thermal stability but suffer from processing difficulties due to their high crystallinity and poor compatibility with hydrophobic polymers. Both starch and cellulose blends encounter biodegradation rate variability and inconsistent barrier properties, limiting their broader use in durable bioplastic products.

Future Trends in Starch and Cellulose Bioplastic Development

Future trends in starch and cellulose bioplastic development emphasize enhancing mechanical properties and biodegradability through advanced blending techniques. Innovations in starch blends often focus on improving compatibility with synthetic polymers to achieve higher tensile strength and water resistance, while cellulose blends prioritize nanocellulose incorporation to boost barrier properties and thermal stability. Research also targets sustainable sourcing and cost-effective processing methods to drive commercial scalability and environmental impact reduction in bioplastic applications.

Starch blends vs Cellulose blends Infographic

materialdif.com

materialdif.com