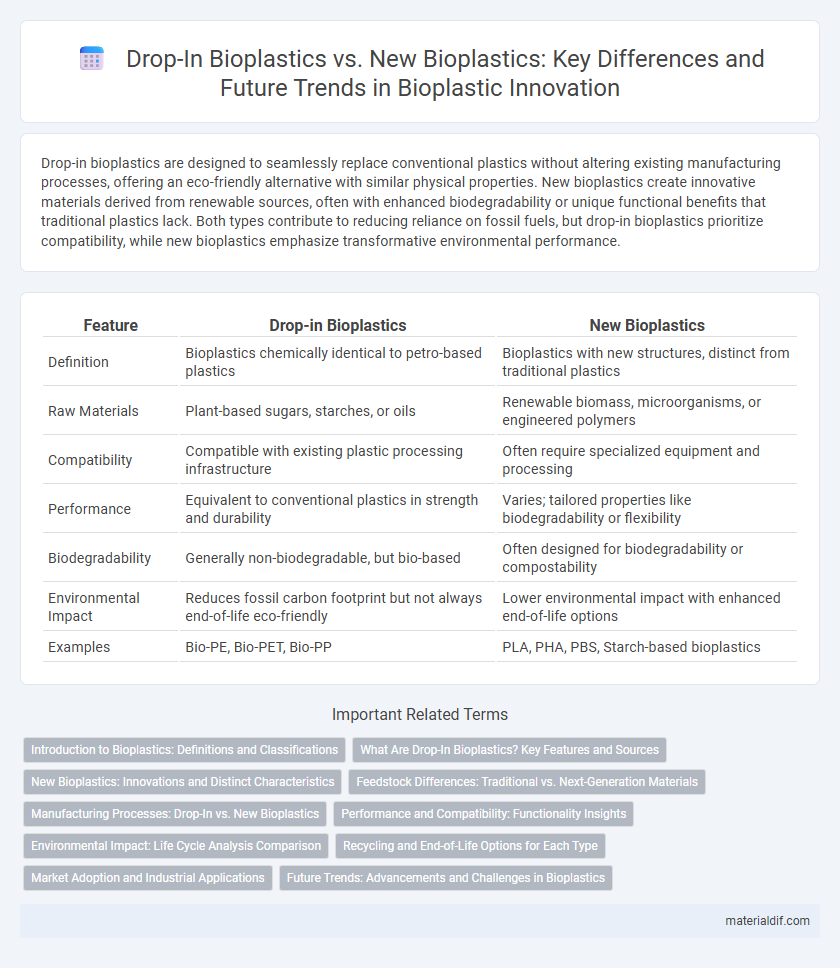

Drop-in bioplastics are designed to seamlessly replace conventional plastics without altering existing manufacturing processes, offering an eco-friendly alternative with similar physical properties. New bioplastics create innovative materials derived from renewable sources, often with enhanced biodegradability or unique functional benefits that traditional plastics lack. Both types contribute to reducing reliance on fossil fuels, but drop-in bioplastics prioritize compatibility, while new bioplastics emphasize transformative environmental performance.

Table of Comparison

| Feature | Drop-in Bioplastics | New Bioplastics |

|---|---|---|

| Definition | Bioplastics chemically identical to petro-based plastics | Bioplastics with new structures, distinct from traditional plastics |

| Raw Materials | Plant-based sugars, starches, or oils | Renewable biomass, microorganisms, or engineered polymers |

| Compatibility | Compatible with existing plastic processing infrastructure | Often require specialized equipment and processing |

| Performance | Equivalent to conventional plastics in strength and durability | Varies; tailored properties like biodegradability or flexibility |

| Biodegradability | Generally non-biodegradable, but bio-based | Often designed for biodegradability or compostability |

| Environmental Impact | Reduces fossil carbon footprint but not always end-of-life eco-friendly | Lower environmental impact with enhanced end-of-life options |

| Examples | Bio-PE, Bio-PET, Bio-PP | PLA, PHA, PBS, Starch-based bioplastics |

Introduction to Bioplastics: Definitions and Classifications

Drop-in bioplastics are bio-based polymers chemically identical to conventional plastics, allowing seamless integration into existing production and recycling systems. New bioplastics, composed of novel bio-based materials, often exhibit unique properties and require specialized processing and waste management techniques. Understanding these classifications aids in evaluating environmental impacts and applications across various industries.

What Are Drop-In Bioplastics? Key Features and Sources

Drop-in bioplastics are bio-based polymers chemically identical to conventional plastics like polyethylene and PET, allowing seamless integration into existing production and recycling systems. Key features include compatibility with current manufacturing processes, identical physical properties to fossil-based counterparts, and reduced carbon footprint due to renewable biomass sources such as corn starch, sugarcane, and cellulose. Their primary advantage lies in enabling a sustainable transition without the need for new infrastructure or product redesign.

New Bioplastics: Innovations and Distinct Characteristics

New bioplastics exhibit distinct characteristics such as enhanced biodegradability, renewable feedstocks, and tailored molecular structures that address limitations found in traditional drop-in bioplastics. Innovations in enzymatic polymerization and bio-based monomer synthesis enable customized material properties like improved barrier functions and mechanical strength. These advancements position new bioplastics as sustainable alternatives with reduced carbon footprints and higher performance in packaging, agriculture, and medical applications.

Feedstock Differences: Traditional vs. Next-Generation Materials

Drop-in bioplastics utilize conventional feedstocks such as corn starch and sugarcane, enabling seamless integration into existing petrochemical production lines while maintaining compatibility with current plastic products. New bioplastics rely on next-generation materials derived from non-food biomass like agricultural residues, algae, and waste gases, promoting sustainability and reducing competition with food resources. This shift in feedstock sources addresses environmental concerns and enhances the biodegradability and carbon footprint of bioplastic products.

Manufacturing Processes: Drop-In vs. New Bioplastics

Drop-in bioplastics integrate seamlessly into existing petrochemical manufacturing processes, allowing production using conventional equipment and infrastructure, which reduces transition costs and complexity. New bioplastics require distinct production methods often involving novel fermentation, polymerization, or chemical modification techniques tailored to bio-based feedstocks, enhancing material properties but demanding specialized facilities. The choice between drop-in and new bioplastics manufacturing processes influences scalability, cost-efficiency, and compatibility with established supply chains in the bioplastics industry.

Performance and Compatibility: Functionality Insights

Drop-in bioplastics, such as bio-based polyethylene and polypropylene, offer seamless compatibility with existing petrochemical processing and recycling infrastructure, maintaining performance standards identical to their fossil-derived counterparts. New bioplastics like polylactic acid (PLA) and polyhydroxyalkanoates (PHA) demonstrate enhanced biodegradability and functional versatility but may require specific processing conditions and tailored applications due to differences in thermal and mechanical properties. Understanding these performance distinctions and compatibility parameters is critical for optimizing material selection in sustainable packaging, automotive, and consumer goods industries.

Environmental Impact: Life Cycle Analysis Comparison

Drop-in bioplastics, designed to be chemically identical to conventional plastics, typically show a reduced carbon footprint by utilizing renewable feedstocks without altering existing processing infrastructure, resulting in lower energy consumption during manufacturing. New bioplastics, synthesizing entirely novel polymers from bio-based sources, often demonstrate improved biodegradability and reduced toxicity, but their life cycle analysis can reveal higher environmental impacts in feedstock cultivation and polymer synthesis stages. Comparing both, drop-in bioplastics generally offer immediate reduction in greenhouse gas emissions, while new bioplastics hold potential for long-term ecological benefits through enhanced compostability and decreased microplastic pollution.

Recycling and End-of-Life Options for Each Type

Drop-in bioplastics, chemically identical to conventional plastics, seamlessly integrate into existing recycling streams, enabling efficient mechanical recycling without contamination issues. New bioplastics often require specialized composting or chemical recycling facilities due to their distinct polymer structures, presenting challenges in current waste management systems. Understanding these differences is critical for optimizing end-of-life strategies and improving the circularity of bioplastic materials.

Market Adoption and Industrial Applications

Drop-in bioplastics, chemically identical to conventional plastics, achieve faster market adoption due to compatibility with existing manufacturing infrastructure, enabling seamless integration in packaging and automotive sectors. New bioplastics, derived from novel bio-based polymers, face slower adoption but offer unique properties like biodegradability and enhanced performance in specialized applications such as medical devices and agriculture films. Industrial adoption trends show increased preference for drop-in bioplastics in large-scale production, while niche markets drive innovation and gradual acceptance of new bioplastics.

Future Trends: Advancements and Challenges in Bioplastics

Drop-in bioplastics, chemically identical to conventional plastics, enable seamless integration into existing production lines, accelerating market adoption while reducing carbon footprints. New bioplastics, derived from novel bio-based materials like algae and lignin, offer enhanced biodegradability and functional properties but face scalability and cost challenges. Future trends emphasize improving feedstock diversity, refining enzymatic processes, and enhancing recycling compatibility to balance environmental benefits with economic viability.

Drop-in bioplastics vs New bioplastics Infographic

materialdif.com

materialdif.com