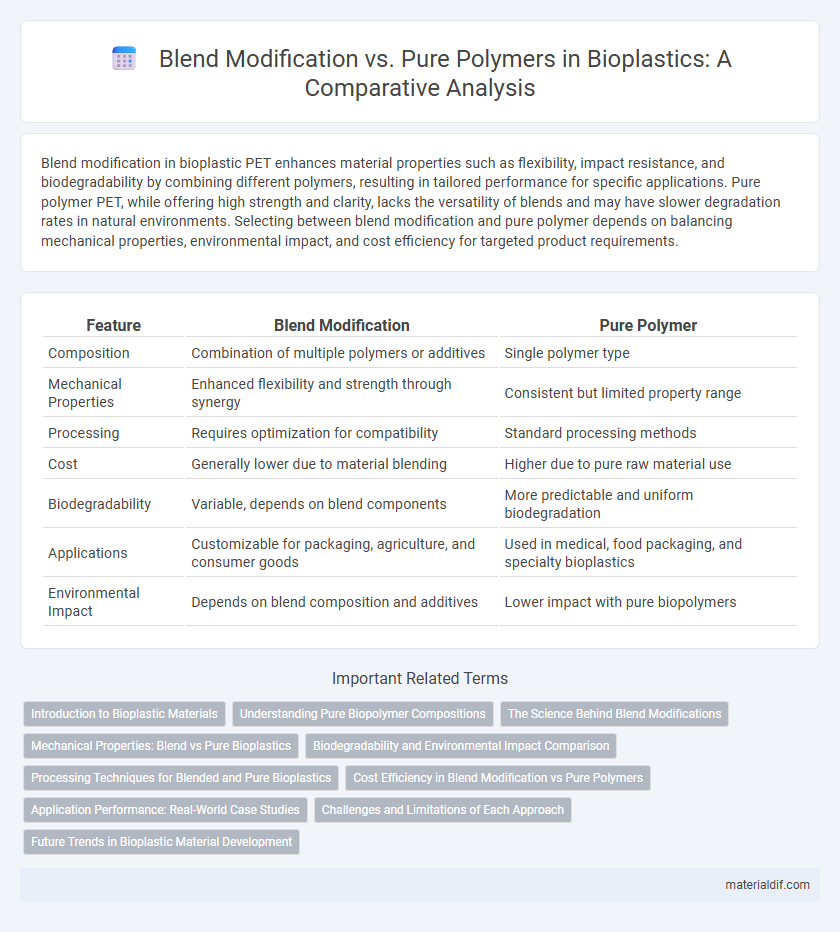

Blend modification in bioplastic PET enhances material properties such as flexibility, impact resistance, and biodegradability by combining different polymers, resulting in tailored performance for specific applications. Pure polymer PET, while offering high strength and clarity, lacks the versatility of blends and may have slower degradation rates in natural environments. Selecting between blend modification and pure polymer depends on balancing mechanical properties, environmental impact, and cost efficiency for targeted product requirements.

Table of Comparison

| Feature | Blend Modification | Pure Polymer |

|---|---|---|

| Composition | Combination of multiple polymers or additives | Single polymer type |

| Mechanical Properties | Enhanced flexibility and strength through synergy | Consistent but limited property range |

| Processing | Requires optimization for compatibility | Standard processing methods |

| Cost | Generally lower due to material blending | Higher due to pure raw material use |

| Biodegradability | Variable, depends on blend components | More predictable and uniform biodegradation |

| Applications | Customizable for packaging, agriculture, and consumer goods | Used in medical, food packaging, and specialty bioplastics |

| Environmental Impact | Depends on blend composition and additives | Lower impact with pure biopolymers |

Introduction to Bioplastic Materials

Blend modification in bioplastic materials enhances mechanical properties, biodegradability, and cost-effectiveness compared to pure polymers. Pure biopolymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) offer biodegradability but often suffer from brittleness and limited thermal stability. Blending these polymers with natural fibers, plasticizers, or other biopolymers improves flexibility, durability, and processability, making bioplastic blends more suitable for diverse applications.

Understanding Pure Biopolymer Compositions

Understanding pure biopolymer compositions involves analyzing the molecular structure and thermal properties unique to materials like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), which influence biodegradability and mechanical strength. Unlike blend modifications, pure biopolymers offer predictable performance without the complications of phase separation or compatibility issues inherent in polymer blends. Characterizing pure biopolymer compositions enables optimization of processing parameters and end-use applications in sustainable packaging and medical devices.

The Science Behind Blend Modifications

Blend modifications in bioplastics enhance material properties by combining polymers at the molecular level, promoting improved mechanical strength, thermal stability, and biodegradability compared to pure polymers. The science behind these modifications involves compatibilization techniques that optimize polymer-polymer interactions, phase morphology, and crystallinity, resulting in tailored performance characteristics. Understanding polymer miscibility and interfacial adhesion is crucial for designing bioplastic blends with superior functionality and environmental benefits.

Mechanical Properties: Blend vs Pure Bioplastics

Blend modification in bioplastics enhances mechanical properties by combining polymers to achieve improved tensile strength, flexibility, and impact resistance compared to pure polymers. Pure bioplastics often exhibit brittleness and lower mechanical performance, limiting their application scope. Blended bioplastic formulations provide tailored mechanical behavior suitable for diverse industrial uses, balancing rigidity and durability effectively.

Biodegradability and Environmental Impact Comparison

Blend modification in bioplastics often enhances biodegradability by combining polymers with additives that accelerate microbial breakdown, resulting in shorter degradation times compared to pure polymers. Pure biopolymers, while inherently biodegradable, may exhibit slower decomposition rates and limited environmental adaptability. The environmental impact of blend-modified bioplastics is generally reduced due to improved compostability and lower persistence in ecosystems, whereas pure polymers sometimes face challenges in diverse waste management conditions.

Processing Techniques for Blended and Pure Bioplastics

Processing techniques for pure bioplastics often involve methods like extrusion, injection molding, and thermoforming, ensuring material homogeneity and predictable degradation rates. In contrast, blend modification requires specialized techniques such as compatibilization, reactive extrusion, and dynamic vulcanization to enhance interfacial adhesion and mechanical properties. Optimization of processing parameters in blended bioplastics is critical for maintaining performance while achieving desired biodegradability and reducing processing challenges like phase separation.

Cost Efficiency in Blend Modification vs Pure Polymers

Blend modification in bioplastics significantly enhances cost efficiency by combining lower-cost natural polymers with high-performance synthetic biopolymers, reducing overall material expenses. Pure polymers often require complex and expensive production processes, which increase the final product cost. Utilizing blend modification allows manufacturers to optimize material properties while maintaining affordability in commercial applications.

Application Performance: Real-World Case Studies

Blend modification in bioplastics enhances application performance by combining polymers to achieve tailored properties such as improved flexibility, strength, and biodegradability. Real-world case studies demonstrate that blend formulations outperform pure polymers in packaging, agriculture, and medical applications by providing optimized mechanical and barrier properties. For instance, PLA-PHA blends show superior compostability and durability compared to pure PLA, meeting specific industry standards for sustainable product development.

Challenges and Limitations of Each Approach

Blend modification of bioplastics often faces challenges in achieving uniform dispersion and compatibility between components, leading to compromised mechanical properties and variable biodegradability. Pure polymer bioplastics offer consistent properties and predictable performance but can suffer from limitations such as higher production costs and restricted thermal stability. Both approaches must address trade-offs between processability, environmental impact, and end-use application requirements to optimize performance.

Future Trends in Bioplastic Material Development

Blend modification in bioplastics enhances mechanical properties and biodegradability compared to pure polymer counterparts, enabling tailored applications across industries. Future trends emphasize sustainable sourcing, improved compatibility of polymer blends, and advancements in enzymatic degradation to accelerate eco-friendly lifecycle. Innovations focus on integrating renewable fillers and nanoscale additives to optimize performance and reduce environmental impact.

Blend modification vs Pure polymer Infographic

materialdif.com

materialdif.com