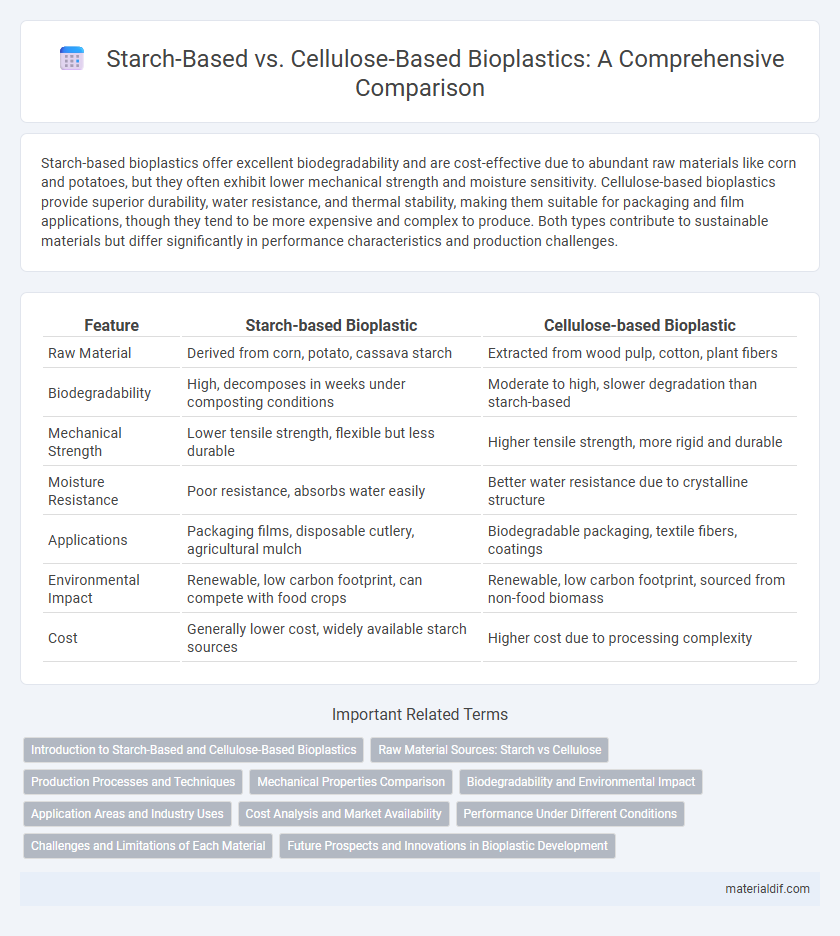

Starch-based bioplastics offer excellent biodegradability and are cost-effective due to abundant raw materials like corn and potatoes, but they often exhibit lower mechanical strength and moisture sensitivity. Cellulose-based bioplastics provide superior durability, water resistance, and thermal stability, making them suitable for packaging and film applications, though they tend to be more expensive and complex to produce. Both types contribute to sustainable materials but differ significantly in performance characteristics and production challenges.

Table of Comparison

| Feature | Starch-based Bioplastic | Cellulose-based Bioplastic |

|---|---|---|

| Raw Material | Derived from corn, potato, cassava starch | Extracted from wood pulp, cotton, plant fibers |

| Biodegradability | High, decomposes in weeks under composting conditions | Moderate to high, slower degradation than starch-based |

| Mechanical Strength | Lower tensile strength, flexible but less durable | Higher tensile strength, more rigid and durable |

| Moisture Resistance | Poor resistance, absorbs water easily | Better water resistance due to crystalline structure |

| Applications | Packaging films, disposable cutlery, agricultural mulch | Biodegradable packaging, textile fibers, coatings |

| Environmental Impact | Renewable, low carbon footprint, can compete with food crops | Renewable, low carbon footprint, sourced from non-food biomass |

| Cost | Generally lower cost, widely available starch sources | Higher cost due to processing complexity |

Introduction to Starch-Based and Cellulose-Based Bioplastics

Starch-based bioplastics derive from natural polymers found in corn, potatoes, and wheat, offering biodegradability and cost-effective production for packaging and agricultural applications. Cellulose-based bioplastics utilize cellulose fibers from wood pulp or cotton, providing enhanced mechanical strength, thermal stability, and higher biodegradability rates compared to starch alternatives. Both types serve as eco-friendly substitutes for conventional plastics, with starch-based bioplastics favored for flexibility and ease of processing, while cellulose-based bioplastics excel in durability and environmental resilience.

Raw Material Sources: Starch vs Cellulose

Starch-based bioplastics are primarily derived from abundant sources such as corn, potato, and wheat, offering a renewable and relatively inexpensive raw material. Cellulose-based bioplastics utilize cellulose extracted from plant cell walls, including wood pulp, cotton, and agricultural residues, providing a more fibrous and structurally complex raw material. The differing molecular structures of starch and cellulose influence the biodegradability and mechanical properties of the resulting bioplastics.

Production Processes and Techniques

Starch-based bioplastics are produced through gelatinization followed by plasticization using additives like glycerol to enhance flexibility, often involving extrusion or injection molding techniques. Cellulose-based bioplastics require chemical modification of cellulose fibers via processes such as etherification or esterification, combined with solvent casting or melt processing to achieve desired film properties. Both production methods emphasize renewable raw materials but differ in processing complexity and final material characteristics.

Mechanical Properties Comparison

Starch-based bioplastics generally exhibit lower tensile strength and flexibility compared to cellulose-based bioplastics, which benefit from the crystalline structure of cellulose fibers providing superior mechanical durability. Cellulose-based bioplastics demonstrate higher modulus of elasticity and better resistance to deformation, making them more suitable for applications requiring enhanced structural integrity. Water absorption tends to reduce the mechanical performance of starch-based bioplastics more significantly than cellulose-based ones due to the hydrophilic nature of starch molecules.

Biodegradability and Environmental Impact

Starch-based bioplastics biodegrade rapidly in composting environments within weeks, releasing fewer greenhouse gases compared to petroleum plastics, but their water sensitivity can limit durability. Cellulose-based bioplastics exhibit slower biodegradation rates, often taking months to fully decompose, yet they offer superior mechanical strength and stability, reducing microplastic pollution. Both types significantly lower carbon footprints and reliance on fossil fuels, with cellulose-based variants providing a more sustainable option for long-term environmental impact.

Application Areas and Industry Uses

Starch-based bioplastics are widely used in packaging, agricultural films, and disposable cutlery due to their biodegradability and low cost, making them ideal for short-term applications. Cellulose-based bioplastics find extensive use in medical devices, cosmetics, and textile industries thanks to their superior mechanical strength, transparency, and moisture resistance. Both materials contribute significantly to sustainable manufacturing, with starch-based options dominating food-related uses while cellulose-based bioplastics support high-performance and durable product needs.

Cost Analysis and Market Availability

Starch-based bioplastics generally offer lower production costs due to abundant raw materials like corn and potatoes, making them more accessible in the global market. In contrast, cellulose-based bioplastics, derived from wood pulp or cotton fibers, involve higher processing expenses but provide superior mechanical properties and biodegradability. Market availability favors starch-based options for disposable packaging, while cellulose-based bioplastics gain traction in specialized applications requiring durability and environmental sustainability.

Performance Under Different Conditions

Starch-based bioplastics exhibit rapid biodegradability and flexibility but tend to degrade quickly in moist and high-temperature environments, limiting their durability. Cellulose-based bioplastics offer superior mechanical strength and thermal stability, maintaining integrity under diverse environmental conditions including humidity and heat. The performance gap is critical for applications requiring long-term stability versus those prioritizing eco-friendly disposability.

Challenges and Limitations of Each Material

Starch-based bioplastics face challenges such as poor water resistance, limited mechanical strength, and susceptibility to microbial degradation, which restrict their use in high-moisture or load-bearing applications. Cellulose-based bioplastics exhibit limitations including complex extraction processes, high production costs, and lower flexibility compared to synthetic plastics, hindering large-scale adoption. Both materials require advancements in processing techniques and material formulations to overcome durability and cost barriers for broader commercialization.

Future Prospects and Innovations in Bioplastic Development

Starch-based bioplastics offer rapid biodegradability and cost-effective production, making them ideal for packaging applications, while ongoing innovations aim to enhance their mechanical strength and moisture resistance. Cellulose-based bioplastics exhibit superior durability and barrier properties, with future developments focusing on nanocellulose integration to improve functionality and expand use in high-performance materials. Advances in enzymatic modification and bio-composite formulations are expected to drive the scalability and sustainability of both starch- and cellulose-derived bioplastics in various industrial sectors.

Starch-based bioplastic vs Cellulose-based bioplastic Infographic

materialdif.com

materialdif.com