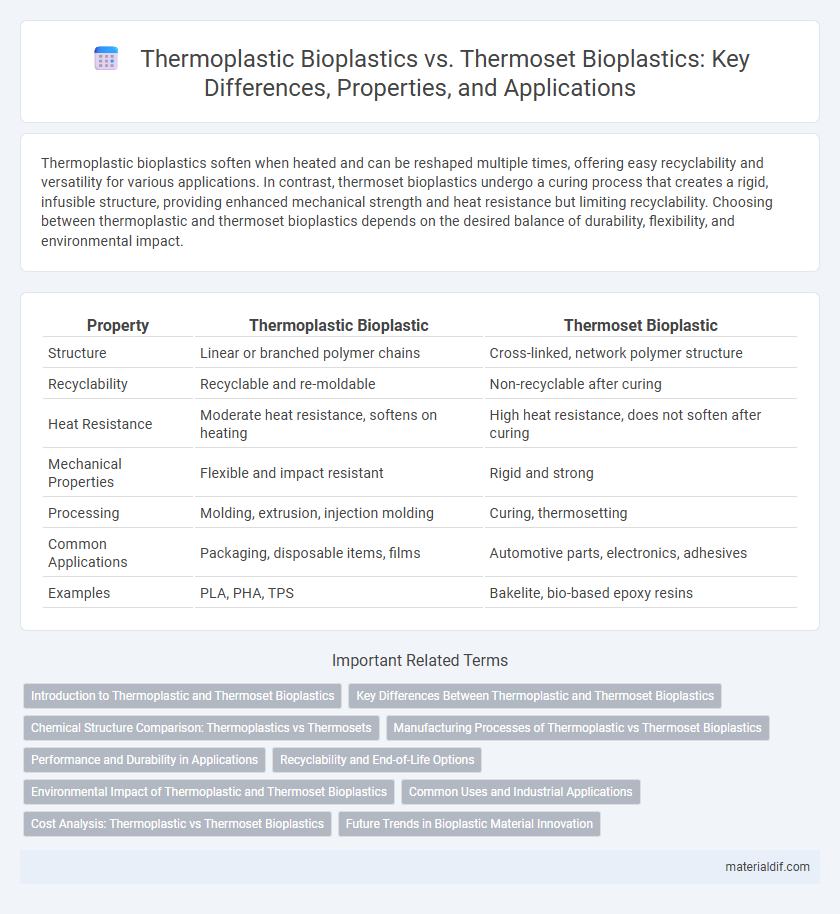

Thermoplastic bioplastics soften when heated and can be reshaped multiple times, offering easy recyclability and versatility for various applications. In contrast, thermoset bioplastics undergo a curing process that creates a rigid, infusible structure, providing enhanced mechanical strength and heat resistance but limiting recyclability. Choosing between thermoplastic and thermoset bioplastics depends on the desired balance of durability, flexibility, and environmental impact.

Table of Comparison

| Property | Thermoplastic Bioplastic | Thermoset Bioplastic |

|---|---|---|

| Structure | Linear or branched polymer chains | Cross-linked, network polymer structure |

| Recyclability | Recyclable and re-moldable | Non-recyclable after curing |

| Heat Resistance | Moderate heat resistance, softens on heating | High heat resistance, does not soften after curing |

| Mechanical Properties | Flexible and impact resistant | Rigid and strong |

| Processing | Molding, extrusion, injection molding | Curing, thermosetting |

| Common Applications | Packaging, disposable items, films | Automotive parts, electronics, adhesives |

| Examples | PLA, PHA, TPS | Bakelite, bio-based epoxy resins |

Introduction to Thermoplastic and Thermoset Bioplastics

Thermoplastic bioplastics consist of polymers that soften when heated and harden upon cooling, enabling repeated reshaping without altering chemical properties, which makes them suitable for applications requiring recyclability and flexibility. Thermoset bioplastics undergo a chemical curing process that creates a cross-linked, rigid structure, providing superior heat resistance and mechanical strength but preventing remelting or reshaping after curing. The distinct thermal behaviors of thermoplastic and thermoset bioplastics influence their processing methods, applications, and environmental recycling potential.

Key Differences Between Thermoplastic and Thermoset Bioplastics

Thermoplastic bioplastics soften upon heating and can be remolded multiple times, making them highly recyclable and versatile for various applications. In contrast, thermoset bioplastics undergo a curing process that creates irreversible cross-linked polymer chains, resulting in a rigid, heat-resistant structure that cannot be reshaped after setting. The key differences lie in their thermal behavior, recyclability, and structural properties, with thermoplastics favored for flexibility and reusability, while thermosets offer superior mechanical strength and thermal stability.

Chemical Structure Comparison: Thermoplastics vs Thermosets

Thermoplastic bioplastics consist of linear or branched polymer chains that soften upon heating, enabling repeated melting and reshaping due to their reversible physical bonds. Thermoset bioplastics feature a highly cross-linked network structure formed by irreversible covalent bonds, which makes them rigid and resistant to remelting after curing. This fundamental difference in chemical structure influences their recyclability, mechanical properties, and thermal stability in bioplastic applications.

Manufacturing Processes of Thermoplastic vs Thermoset Bioplastics

Thermoplastic bioplastics are manufactured through processes such as injection molding, extrusion, and thermoforming, allowing them to be melted and reshaped multiple times without chemical change. In contrast, thermoset bioplastics undergo irreversible curing through heat, chemicals, or irradiation, forming cross-linked polymers that cannot be remelted or reshaped. The manufacturing of thermoset bioplastics typically involves resin transfer molding or compression molding, enabling durable and heat-resistant products.

Performance and Durability in Applications

Thermoplastic bioplastics exhibit superior performance in applications requiring repeated reshaping and recycling due to their ability to soften upon heating and harden upon cooling. Thermoset bioplastics offer enhanced durability and chemical resistance, making them ideal for high-stress, temperature-resistant applications where structural integrity must be maintained under harsh conditions. The choice between thermoplastic and thermoset bioplastics depends on the specific demands of flexibility, mechanical strength, and environmental exposure in targeted end-use scenarios.

Recyclability and End-of-Life Options

Thermoplastic bioplastics are recyclable through mechanical reprocessing, allowing them to be melted and reshaped multiple times without significant degradation, supporting circular economy initiatives. In contrast, thermoset bioplastics have a cross-linked polymer structure that prevents melting, making them non-recyclable by conventional methods and typically relegated to composting or energy recovery at end-of-life. Choosing thermoplastic bioplastics enhances recyclability and reduces environmental impact compared to thermoset options, which are limited in their post-use recovery pathways.

Environmental Impact of Thermoplastic and Thermoset Bioplastics

Thermoplastic bioplastics generally have a lower environmental impact due to their recyclability and ability to be reprocessed multiple times, reducing waste and resource consumption. In contrast, thermoset bioplastics form irreversible chemical bonds, making recycling difficult and often resulting in landfill disposal, which contributes to long-term environmental burdens. The choice between the two significantly influences waste management strategies and the sustainability of bioplastic applications.

Common Uses and Industrial Applications

Thermoplastic bioplastics, known for their ability to be melted and reshaped, are commonly used in packaging, agricultural films, and disposable cutlery, offering versatility and recyclability in industries such as food service and retail. Thermoset bioplastics, curing into a permanent, heat-resistant form, find industrial applications in automotive parts, electrical insulation, and durable consumer goods, where structural strength and high thermal stability are critical. The distinct curing and reheating properties determine their suitability across sectors prioritizing either flexibility and recyclability or mechanical robustness and heat resistance.

Cost Analysis: Thermoplastic vs Thermoset Bioplastics

Thermoplastic bioplastics typically offer lower production costs due to their recyclability and ease of processing, which reduces energy consumption during manufacturing. Thermoset bioplastics incur higher initial expenses as their irreversible curing process demands more energy and specialized molds, increasing tooling and maintenance costs. Cost analysis favors thermoplastics for applications requiring scalability and recyclability, while thermosets are more cost-effective in high-performance, durable components despite their higher upfront investment.

Future Trends in Bioplastic Material Innovation

Thermoplastic bioplastics, characterized by their ability to be repeatedly melted and reshaped, are driving future trends in sustainable packaging and 3D printing technologies due to their recyclability and versatility. Thermoset bioplastics, which form irreversible chemical bonds, are gaining attention for high-performance applications such as automotive parts and electronic casings because of their superior heat resistance and mechanical strength. Innovations in bio-based composites and improved biodegradability are accelerating the development of both thermoplastic and thermoset bioplastics, enhancing environmental impact and functional properties.

Thermoplastic bioplastic vs Thermoset bioplastic Infographic

materialdif.com

materialdif.com