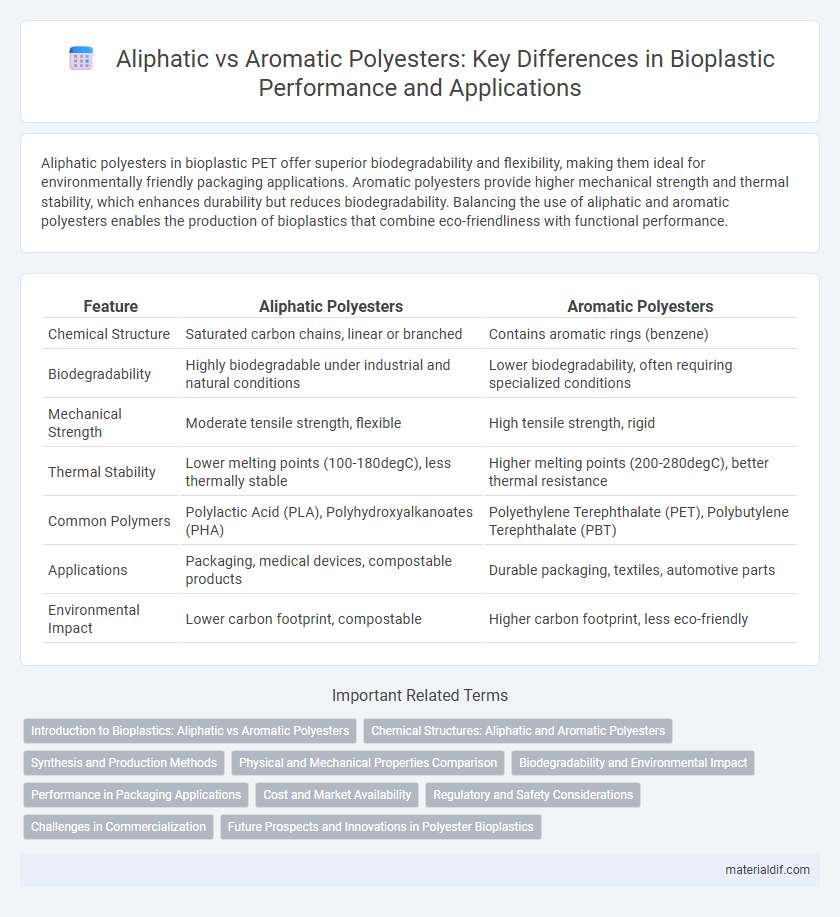

Aliphatic polyesters in bioplastic PET offer superior biodegradability and flexibility, making them ideal for environmentally friendly packaging applications. Aromatic polyesters provide higher mechanical strength and thermal stability, which enhances durability but reduces biodegradability. Balancing the use of aliphatic and aromatic polyesters enables the production of bioplastics that combine eco-friendliness with functional performance.

Table of Comparison

| Feature | Aliphatic Polyesters | Aromatic Polyesters |

|---|---|---|

| Chemical Structure | Saturated carbon chains, linear or branched | Contains aromatic rings (benzene) |

| Biodegradability | Highly biodegradable under industrial and natural conditions | Lower biodegradability, often requiring specialized conditions |

| Mechanical Strength | Moderate tensile strength, flexible | High tensile strength, rigid |

| Thermal Stability | Lower melting points (100-180degC), less thermally stable | Higher melting points (200-280degC), better thermal resistance |

| Common Polymers | Polylactic Acid (PLA), Polyhydroxyalkanoates (PHA) | Polyethylene Terephthalate (PET), Polybutylene Terephthalate (PBT) |

| Applications | Packaging, medical devices, compostable products | Durable packaging, textiles, automotive parts |

| Environmental Impact | Lower carbon footprint, compostable | Higher carbon footprint, less eco-friendly |

Introduction to Bioplastics: Aliphatic vs Aromatic Polyesters

Aliphatic polyesters, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), are biodegradable bioplastics derived from renewable resources, offering excellent environmental benefits due to their compostability and reduced carbon footprint. Aromatic polyesters, like polyethylene terephthalate (PET) and polybutylene terephthalate (PBT), provide superior mechanical strength and thermal stability but have limited biodegradability compared to aliphatic counterparts. Choosing between aliphatic and aromatic polyesters depends on the specific application requirements, balancing sustainability, performance, and end-of-life disposal options.

Chemical Structures: Aliphatic and Aromatic Polyesters

Aliphatic polyesters consist of straight or branched chains primarily made of carbon and hydrogen atoms, resulting in flexible and biodegradable materials with ester linkages between aliphatic units. Aromatic polyesters feature benzene rings within their backbone, imparting rigidity, thermal stability, and resistance to biodegradation due to the aromatic ring's resonance stabilization. The chemical structure differences between aliphatic and aromatic polyesters significantly influence their mechanical properties, degradation rates, and applications in bioplastic development.

Synthesis and Production Methods

Aliphatic polyesters are primarily synthesized through ring-opening polymerization of lactones or polycondensation of hydroxy acids, utilizing catalysts such as tin(II) octoate for controlled molecular weight and properties. Aromatic polyesters, including polyethylene terephthalate (PET), are produced via polycondensation reactions between aromatic dicarboxylic acids and diols, often requiring high temperatures and vacuum conditions to drive the reaction to completion. Production methods for aliphatic polyesters typically emphasize biodegradability and renewable feedstocks, while aromatic polyester synthesis focuses on achieving high thermal stability and mechanical strength for durable applications.

Physical and Mechanical Properties Comparison

Aliphatic polyesters, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), exhibit higher flexibility and biodegradability but generally have lower thermal resistance and mechanical strength compared to aromatic polyesters like polyethylene terephthalate (PET). Aromatic polyesters offer superior tensile strength, stiffness, and dimensional stability, making them suitable for applications requiring durability and heat resistance. The choice between aliphatic and aromatic polyesters depends on balancing biodegradability with mechanical and physical property requirements for targeted bioplastic applications.

Biodegradability and Environmental Impact

Aliphatic polyesters such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) exhibit superior biodegradability due to their simpler molecular structure, allowing complete microbial decomposition in composting environments within months. Aromatic polyesters like polyethylene terephthalate (PET) possess aromatic rings that confer rigidity and resistance to biodegradation, leading to persistent environmental accumulation and microplastic pollution. The environmental impact of aliphatic polyesters is significantly lower, as their degradation contributes to reduced landfill waste and lower greenhouse gas emissions compared to aromatic counterparts.

Performance in Packaging Applications

Aliphatic polyesters such as polylactic acid (PLA) offer excellent biodegradability and transparency, making them suitable for compostable packaging with moderate barrier properties. Aromatic polyesters like polyethylene terephthalate (PET) provide superior mechanical strength, thermal stability, and gas barrier performance, which ensures extended shelf life for packaged goods. Combining aliphatic and aromatic segments in copolymers can optimize both environmental benefits and packaging durability.

Cost and Market Availability

Aliphatic polyesters generally offer lower production costs and greater biodegradability, making them more attractive for sustainable packaging markets. Aromatic polyesters tend to be more expensive due to complex synthesis processes but dominate in applications requiring superior mechanical strength and thermal stability. Market availability of aliphatic polyesters is rapidly increasing, while aromatic polyesters remain prevalent in specialized industrial uses.

Regulatory and Safety Considerations

Aliphatic polyesters, such as polylactic acid (PLA), typically exhibit better biodegradability and lower toxicity profiles, making them more favorable under stringent regulatory frameworks like FDA and REACH standards for food contact applications. Aromatic polyesters, including polyethylene terephthalate (PET), pose challenges due to slower degradation rates and potential release of aromatic compounds, triggering closer regulatory scrutiny regarding long-term environmental and human health impacts. Compliance with global safety regulations demands thorough risk assessments and migration testing to ensure that both types meet criteria for safe use in bioplastic products.

Challenges in Commercialization

Aliphatic polyesters such as polylactic acid (PLA) face challenges in commercialization due to lower thermal stability and slower biodegradation rates compared to aromatic polyesters like polyethylene terephthalate (PET), which offer superior mechanical strength and durability but struggle with environmental persistence. High production costs and limited sourcing of renewable feedstocks further impede large-scale adoption of aliphatic variants. Aromatic polyesters often require complex recycling processes, complicating their integration into circular economy models despite their favorable performance characteristics.

Future Prospects and Innovations in Polyester Bioplastics

Aliphatic polyesters, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), are gaining traction for their biodegradability and renewable feedstock compatibility, positioning them at the forefront of sustainable packaging and medical applications. Aromatic polyesters like polyethylene terephthalate (PET), traditionally derived from fossil fuels, are being innovated with bio-based alternatives and enhanced recyclability to reduce environmental impact while maintaining mechanical performance. Future prospects in polyester bioplastics emphasize the development of hybrid materials combining aliphatic and aromatic segments to optimize biodegradability, durability, and cost-efficiency, supported by advances in enzymatic recycling and microbial synthesis technologies.

Aliphatic polyesters vs Aromatic polyesters Infographic

materialdif.com

materialdif.com