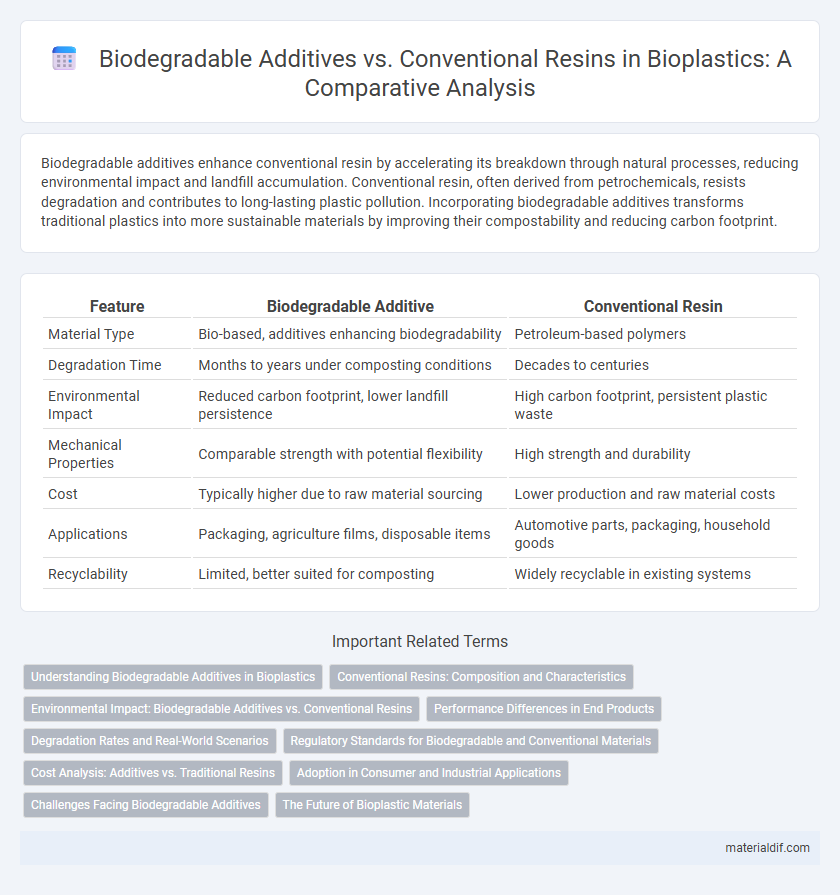

Biodegradable additives enhance conventional resin by accelerating its breakdown through natural processes, reducing environmental impact and landfill accumulation. Conventional resin, often derived from petrochemicals, resists degradation and contributes to long-lasting plastic pollution. Incorporating biodegradable additives transforms traditional plastics into more sustainable materials by improving their compostability and reducing carbon footprint.

Table of Comparison

| Feature | Biodegradable Additive | Conventional Resin |

|---|---|---|

| Material Type | Bio-based, additives enhancing biodegradability | Petroleum-based polymers |

| Degradation Time | Months to years under composting conditions | Decades to centuries |

| Environmental Impact | Reduced carbon footprint, lower landfill persistence | High carbon footprint, persistent plastic waste |

| Mechanical Properties | Comparable strength with potential flexibility | High strength and durability |

| Cost | Typically higher due to raw material sourcing | Lower production and raw material costs |

| Applications | Packaging, agriculture films, disposable items | Automotive parts, packaging, household goods |

| Recyclability | Limited, better suited for composting | Widely recyclable in existing systems |

Understanding Biodegradable Additives in Bioplastics

Biodegradable additives in bioplastics enhance the material's ability to break down rapidly under specific environmental conditions, unlike conventional resin which resists degradation and persists in ecosystems. These additives are typically composed of organic compounds such as starch, cellulose, or additives derived from natural polymers that promote microbial activity and enzymatic breakdown. Understanding the role and composition of biodegradable additives is crucial for optimizing bioplastic formulations to achieve desired decomposition rates and reduce environmental impact.

Conventional Resins: Composition and Characteristics

Conventional resins primarily consist of petroleum-based polymers such as polyethylene (PE), polypropylene (PP), and polystyrene (PS), known for their durability, flexibility, and cost-effectiveness. These resins exhibit high mechanical strength, chemical resistance, and long shelf life, which contribute to their widespread use in packaging and manufacturing. However, their non-biodegradable nature results in persistent environmental pollution and challenges in waste management.

Environmental Impact: Biodegradable Additives vs. Conventional Resins

Biodegradable additives accelerate the decomposition of bioplastics by enabling microbial breakdown, significantly reducing landfill accumulation and environmental pollution compared to conventional resins derived from petrochemicals. Conventional resins persist in ecosystems for hundreds of years, contributing to microplastic contamination and greenhouse gas emissions, while biodegradable additives promote sustainable waste management by improving compostability and reducing carbon footprint. The incorporation of biodegradable additives in plastic formulations supports circular economy principles, enhancing resource efficiency and mitigating long-term ecological damage.

Performance Differences in End Products

Biodegradable additives in bioplastics enhance environmental sustainability by accelerating decomposition rates compared to conventional resins, which persist longer in ecosystems. Performance differences include reduced mechanical strength and thermal resistance in biodegradable blends, affecting durability and application range. Conventional resins offer superior tensile strength and heat stability, making them preferable for long-lasting products but less eco-friendly.

Degradation Rates and Real-World Scenarios

Biodegradable additives in plastics significantly accelerate degradation rates compared to conventional resins, often breaking down within months under composting conditions, whereas traditional resins may persist for decades in the environment. Real-world scenarios such as landfill and marine environments reveal that biodegradable additives enhance polymer fragmentation and microbial assimilation, promoting faster decomposition. However, biodegradation efficacy depends on factors like temperature, moisture, and microbial presence, making conventional resins more environmentally persistent.

Regulatory Standards for Biodegradable and Conventional Materials

Regulatory standards for biodegradable additives require compliance with specific certifications such as ASTM D6400 and EN 13432, ensuring materials break down under industrial composting conditions within a defined timeframe. Conventional resins, primarily petroleum-based, follow different regulatory frameworks focused on chemical safety and environmental emissions rather than degradation. Understanding these distinct regulatory landscapes is crucial for manufacturers aiming to develop or market eco-friendly products aligned with environmental policies and consumer expectations.

Cost Analysis: Additives vs. Traditional Resins

Biodegradable additives typically increase the cost of bioplastics compared to traditional resins due to higher raw material prices and specialized processing requirements. Conventional resins benefit from established supply chains and economies of scale, resulting in lower overall production costs. Despite the initial expense, biodegradable additives offer potential long-term savings through reduced environmental compliance costs and improved market demand for sustainable materials.

Adoption in Consumer and Industrial Applications

Biodegradable additives enhance conventional resin by accelerating decomposition, making them increasingly favored in consumer goods such as packaging, disposable cutlery, and agricultural films, where environmental impact is a critical concern. Industrial applications benefit from these additives by meeting stricter regulatory standards and sustainability targets, promoting wider adoption in sectors like automotive and electronics. The shift toward biodegradable additive-infused resins addresses the demand for eco-friendly materials without compromising performance, driving growth in both consumer and industrial markets.

Challenges Facing Biodegradable Additives

Biodegradable additives often face challenges such as limited compatibility with conventional resins, leading to reduced mechanical performance and processing difficulties. These additives can also accelerate the degradation of polymers under unintended conditions, causing premature material failure. Furthermore, inconsistent biodegradation rates and high production costs limit widespread adoption in industries reliant on conventional resin formulations.

The Future of Bioplastic Materials

Biodegradable additives enhance conventional resins by accelerating decomposition, reducing plastic pollution and environmental impact. These additives enable bioplastics to break down more efficiently in natural settings compared to traditional petrochemical-based resins. Innovations in biodegradable compounds and resin formulations are driving the future of sustainable packaging and eco-friendly materials in the plastics industry.

Biodegradable additive vs Conventional resin Infographic

materialdif.com

materialdif.com