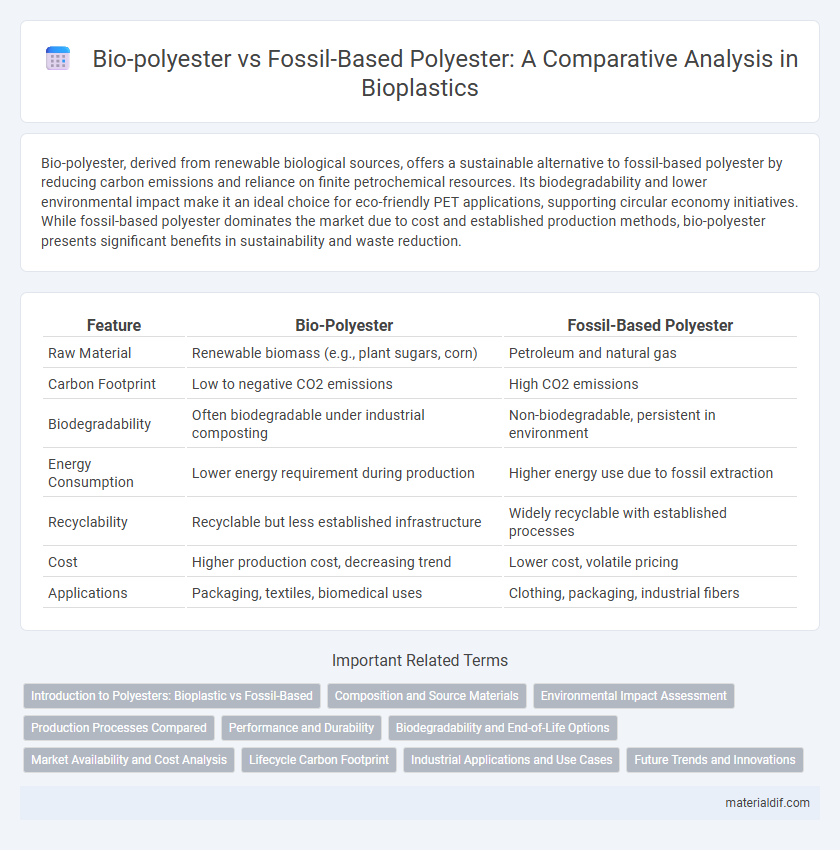

Bio-polyester, derived from renewable biological sources, offers a sustainable alternative to fossil-based polyester by reducing carbon emissions and reliance on finite petrochemical resources. Its biodegradability and lower environmental impact make it an ideal choice for eco-friendly PET applications, supporting circular economy initiatives. While fossil-based polyester dominates the market due to cost and established production methods, bio-polyester presents significant benefits in sustainability and waste reduction.

Table of Comparison

| Feature | Bio-Polyester | Fossil-Based Polyester |

|---|---|---|

| Raw Material | Renewable biomass (e.g., plant sugars, corn) | Petroleum and natural gas |

| Carbon Footprint | Low to negative CO2 emissions | High CO2 emissions |

| Biodegradability | Often biodegradable under industrial composting | Non-biodegradable, persistent in environment |

| Energy Consumption | Lower energy requirement during production | Higher energy use due to fossil extraction |

| Recyclability | Recyclable but less established infrastructure | Widely recyclable with established processes |

| Cost | Higher production cost, decreasing trend | Lower cost, volatile pricing |

| Applications | Packaging, textiles, biomedical uses | Clothing, packaging, industrial fibers |

Introduction to Polyesters: Bioplastic vs Fossil-Based

Bio-polyesters, derived from renewable biomass sources such as corn starch and sugarcane, offer a sustainable alternative to fossil-based polyesters, which are synthesized from petrochemical feedstocks like ethylene glycol and terephthalic acid. Bioplastic polyesters, including polylactic acid (PLA) and polyhydroxyalkanoates (PHA), exhibit biodegradability and reduced carbon footprint compared to traditional polyethylene terephthalate (PET) used in fossil-based polyester production. Advances in bio-polyester technology emphasize renewable raw materials and lower greenhouse gas emissions, addressing environmental concerns associated with conventional polyester manufacturing.

Composition and Source Materials

Bio-polyester is derived from renewable resources such as plant-based sugars and starches, making it a sustainable alternative to fossil-based polyester, which is produced from petrochemical raw materials like petroleum and natural gas. The molecular composition of bio-polyester often includes monomers like polylactic acid (PLA) produced through fermentation processes, whereas fossil-based polyester primarily consists of polyethylene terephthalate (PET) synthesized from terephthalic acid and ethylene glycol. This fundamental difference in source materials contributes to bio-polyester's reduced carbon footprint and improved biodegradability compared to conventional fossil-based polyester.

Environmental Impact Assessment

Bio-polyester significantly reduces greenhouse gas emissions compared to fossil-based polyester, as it is derived from renewable resources like plant biomass. Life cycle assessments highlight lower carbon footprints and reduced dependency on non-renewable petroleum sources in bio-polyester production. Furthermore, bio-polyesters often demonstrate improved biodegradability, mitigating long-term environmental pollution associated with conventional synthetic polyesters.

Production Processes Compared

Bio-polyester production involves the fermentation of renewable resources such as sugarcane or corn, resulting in polymers like polylactic acid (PLA) that are biodegradable and have a lower carbon footprint. Fossil-based polyester is synthesized from petrochemical feedstocks through energy-intensive processes like polymerization of purified terephthalic acid (PTA) and monoethylene glycol (MEG), generating significant greenhouse gas emissions. The bio-polyester manufacturing process generally requires less energy and produces fewer toxic byproducts compared to the traditional fossil-based polyester production.

Performance and Durability

Bio-polyester offers comparable performance to fossil-based polyester, exhibiting similar tensile strength, elasticity, and abrasion resistance critical for textile and packaging applications. Its durability extends to resistance against UV degradation and chemical exposure, supporting long-term use in diverse environments. Advances in bio-polyester formulations continue to close the gap in thermal stability and moisture absorption, enhancing its suitability as a sustainable alternative in high-performance applications.

Biodegradability and End-of-Life Options

Bio-polyester offers superior biodegradability compared to fossil-based polyester, breaking down more efficiently in industrial composting environments and reducing plastic pollution. Its end-of-life options include composting and recycling, which support circular economy models and minimize landfill accumulation. Fossil-based polyester, derived from petrochemicals, resists degradation and primarily relies on mechanical recycling or incineration, leading to longer environmental persistence and higher carbon emissions.

Market Availability and Cost Analysis

Bio-polyester, derived from renewable biomass such as corn or sugarcane, is increasingly available in global markets but still represents a smaller share compared to fossil-based polyester due to production scale and supply chain maturity. Market analysis shows that bio-polyesters typically incur 20-30% higher costs than fossil-based counterparts, influenced by feedstock prices and less optimized manufacturing processes. Despite higher costs, growing demand for sustainable materials and regulatory incentives drive investments to scale bio-polyester production, gradually reducing price gaps and enhancing market accessibility.

Lifecycle Carbon Footprint

Bio-polyesters demonstrate a significantly lower lifecycle carbon footprint compared to fossil-based polyesters due to their renewable feedstocks and reduced greenhouse gas emissions during production. The carbon sequestration capacity of biomass used in bio-polyester manufacturing further decreases overall emissions. Lifecycle assessments reveal bio-polyesters can reduce carbon emissions by up to 60% relative to conventional fossil-derived polyester.

Industrial Applications and Use Cases

Bio-polyester offers a sustainable alternative in industrial applications such as packaging, textiles, and automotive components, providing comparable durability and flexibility to fossil-based polyester. Its biodegradability and lower carbon footprint make it ideal for environmentally-conscious manufacturing, especially in single-use products and disposable items. Fossil-based polyester remains prevalent in high-performance applications requiring exceptional strength and heat resistance, but increasing demand for eco-friendly materials drives a shift toward bio-polyester integration.

Future Trends and Innovations

Bio-polyester production is rapidly advancing through enzymatic recycling and microbial synthesis, promising enhanced biodegradability and reduced carbon footprint compared to fossil-based polyester. Emerging innovations include fully bio-based polyesters derived from renewable feedstocks like lignocellulosic biomass, enabling circular economy models and lowering dependency on petrochemicals. Future trends emphasize integration with green chemistry and AI-driven process optimization to boost efficiency and sustainability in bioplastic manufacturing.

Bio-polyester vs Fossil-based polyester Infographic

materialdif.com

materialdif.com