Lactic acid polymerization produces polylactic acid (PLA) by chemically synthesizing lactic acid monomers into long polymer chains, resulting in controlled molecular weight and consistent material properties ideal for bioplastic applications. Fermentation generates lactic acid through microbial conversion of sugars, offering a renewable and sustainable method to obtain the raw monomer for subsequent polymerization. Combining fermentation for lactic acid production with polymerization techniques ensures efficient and eco-friendly bioplastic manufacturing processes.

Table of Comparison

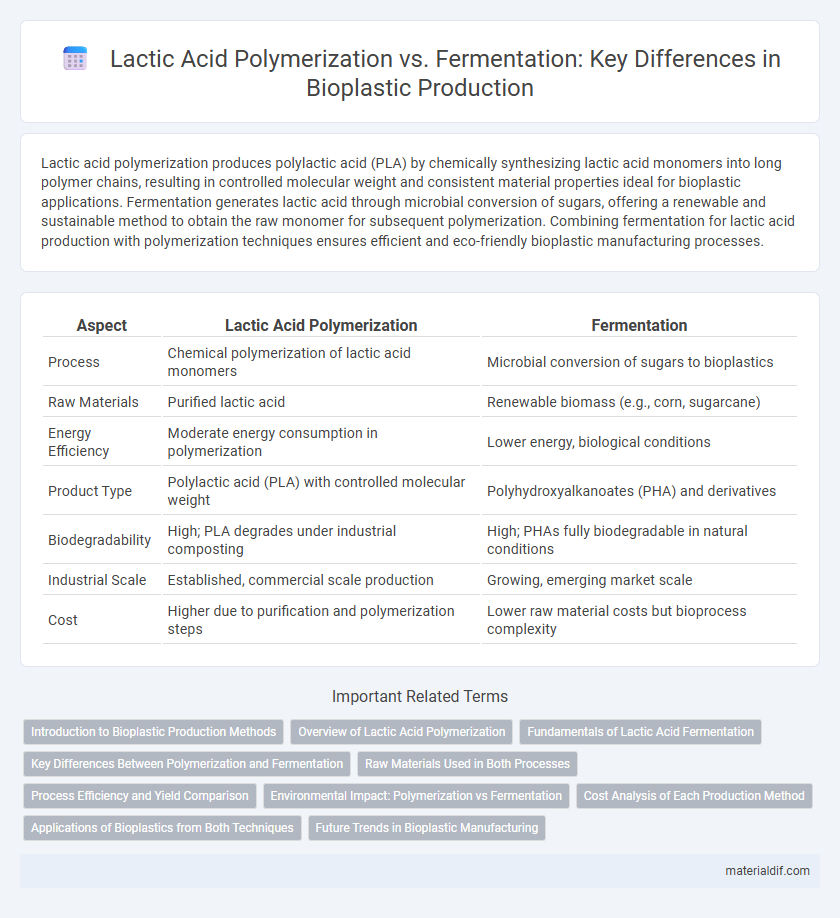

| Aspect | Lactic Acid Polymerization | Fermentation |

|---|---|---|

| Process | Chemical polymerization of lactic acid monomers | Microbial conversion of sugars to bioplastics |

| Raw Materials | Purified lactic acid | Renewable biomass (e.g., corn, sugarcane) |

| Energy Efficiency | Moderate energy consumption in polymerization | Lower energy, biological conditions |

| Product Type | Polylactic acid (PLA) with controlled molecular weight | Polyhydroxyalkanoates (PHA) and derivatives |

| Biodegradability | High; PLA degrades under industrial composting | High; PHAs fully biodegradable in natural conditions |

| Industrial Scale | Established, commercial scale production | Growing, emerging market scale |

| Cost | Higher due to purification and polymerization steps | Lower raw material costs but bioprocess complexity |

Introduction to Bioplastic Production Methods

Lactic acid polymerization and fermentation represent two primary methods in bioplastic production, each leveraging renewable biomass as a feedstock. Fermentation converts sugars into lactic acid using microbial cultures, which is then purified and polymerized to produce polylactic acid (PLA), a common biodegradable polymer. Polymerization methods include direct condensation and ring-opening polymerization, offering control over molecular weight and polymer properties essential for various bioplastic applications.

Overview of Lactic Acid Polymerization

Lactic acid polymerization primarily involves the ring-opening polymerization of lactide, a cyclic dimer of lactic acid, resulting in high-molecular-weight polylactic acid (PLA) with superior mechanical properties compared to direct condensation methods. This process allows precise control over polymer chain length and stereochemistry, enhancing PLA's thermal stability and biodegradability. Industrial-scale polymerization techniques also improve PLA purity, making it suitable for applications in packaging, biomedical devices, and environmentally friendly plastics.

Fundamentals of Lactic Acid Fermentation

Lactic acid fermentation is a biological process where microorganisms convert carbohydrates, primarily glucose, into lactic acid under anaerobic conditions, serving as a crucial step for producing polylactic acid (PLA) bioplastics. This fermentation involves bacteria such as Lactobacillus species, which metabolize sugars to generate optically pure lactic acid, essential for synthesizing high-quality, biodegradable polymers. Understanding the metabolic pathways and maintaining controlled fermentation parameters like pH, temperature, and nutrient supply are fundamental to optimizing lactic acid yield for sustainable bioplastic production.

Key Differences Between Polymerization and Fermentation

Lactic acid polymerization involves chemically linking lactic acid monomers to form polylactic acid (PLA) with precise control over molecular weight and polymer properties, while fermentation is a biological process using microbial cultures to produce lactic acid from renewable resources. Polymerization typically enables higher purity and uniformity in bioplastics, whereas fermentation focuses on sustainable lactic acid production as a precursor. Key differences lie in the process mechanism, control over end-product characteristics, and scalability in bioplastic manufacturing.

Raw Materials Used in Both Processes

Lactic acid polymerization primarily utilizes purified lactic acid derived from renewable carbohydrate sources such as corn starch or sugarcane, enabling controlled synthesis of polylactic acid (PLA) with customizable properties. Fermentation relies on microbial conversion of biomass including glucose, sucrose, or cellulose-rich feedstocks to produce lactic acid or directly synthesize bioplastics, favoring diverse and sustainable raw materials. Both processes emphasize renewable inputs, but polymerization requires high-purity lactic acid, whereas fermentation processes accommodate more complex and variable substrates.

Process Efficiency and Yield Comparison

Lactic acid polymerization offers higher process efficiency with faster reaction times and greater control over molecular weight compared to fermentation methods. Fermentation yields lactic acid biologically but often requires longer processing times and presents variability due to microbial activity. Polymerization directly from purified lactic acid results in higher purity PLA with superior mechanical properties, making it preferable for industrial-scale bioplastic production.

Environmental Impact: Polymerization vs Fermentation

Lactic acid polymerization and fermentation both produce bioplastics but differ significantly in environmental impact; fermentation relies on renewable biomass and generates fewer greenhouse gas emissions compared to traditional polymerization, which often depends on petrochemical processes. Fermentation processes utilize microorganisms to convert sugars into lactic acid, minimizing energy consumption and waste, whereas polymerization may involve high temperatures and toxic catalysts resulting in higher ecological footprints. Optimizing fermentation for large-scale lactic acid production promotes sustainable bioplastic manufacturing with lower carbon intensity and enhanced biodegradability.

Cost Analysis of Each Production Method

Lactic acid polymerization involves chemical synthesis from purified lactic acid, yielding polylactic acid (PLA) with higher production costs due to expensive catalysts and energy-intensive processing. Fermentation produces lactic acid by microbial conversion of renewable biomass, reducing raw material expenses but incurring costs in fermentation optimization and downstream purification. Cost analysis shows fermentation offers a lower-cost route at scale, while polymerization provides purer PLA suitable for high-performance applications despite higher expenses.

Applications of Bioplastics from Both Techniques

Bioplastics derived from lactic acid polymerization, such as polylactic acid (PLA), are extensively used in packaging, agricultural films, and medical implants due to their biodegradability and mechanical strength. Fermentation-based bioplastics like polyhydroxyalkanoates (PHAs) find applications in disposable items, biomedical devices, and automotive parts because of their biocompatibility and resistance to environmental stress. Both techniques contribute significantly to sustainable product development by offering versatile materials tailored for specific industrial needs.

Future Trends in Bioplastic Manufacturing

Lactic acid polymerization offers enhanced control over molecular weight and polymer structure, enabling the production of tailor-made polylactic acid (PLA) bioplastics with improved mechanical properties and biodegradability. Fermentation remains a cost-effective and sustainable route for large-scale lactic acid production, leveraging genetically engineered microbes to increase yield and reduce feedstock costs. Future trends in bioplastic manufacturing emphasize integrating advanced fermentation techniques with novel polymerization processes to create high-performance, eco-friendly materials that align with circular economy principles.

Lactic Acid Polymerization vs Fermentation Infographic

materialdif.com

materialdif.com