Thermoplastic starch and thermoplastic cellulose are two prominent bioplastics derived from renewable resources with distinct properties and applications. Thermoplastic starch, made from natural starch sources, is biodegradable and cost-effective but tends to have lower mechanical strength and water resistance compared to thermoplastic cellulose. Thermoplastic cellulose, processed from cellulose fibers, offers superior durability, flexibility, and moisture resistance, making it suitable for more demanding packaging and industrial uses.

Table of Comparison

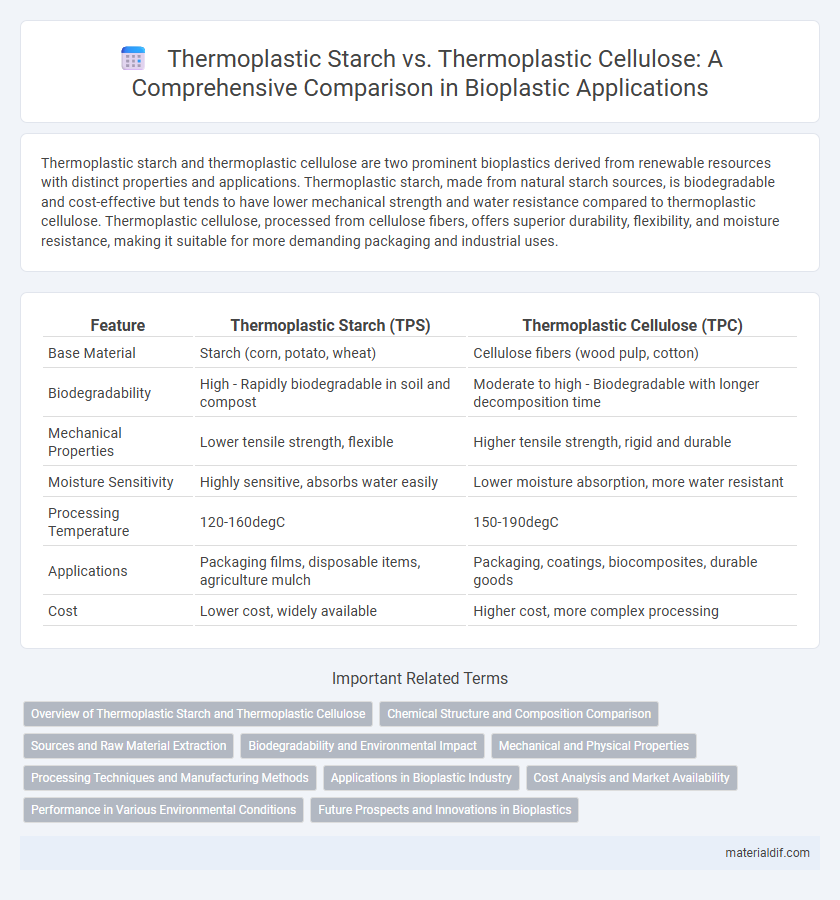

| Feature | Thermoplastic Starch (TPS) | Thermoplastic Cellulose (TPC) |

|---|---|---|

| Base Material | Starch (corn, potato, wheat) | Cellulose fibers (wood pulp, cotton) |

| Biodegradability | High - Rapidly biodegradable in soil and compost | Moderate to high - Biodegradable with longer decomposition time |

| Mechanical Properties | Lower tensile strength, flexible | Higher tensile strength, rigid and durable |

| Moisture Sensitivity | Highly sensitive, absorbs water easily | Lower moisture absorption, more water resistant |

| Processing Temperature | 120-160degC | 150-190degC |

| Applications | Packaging films, disposable items, agriculture mulch | Packaging, coatings, biocomposites, durable goods |

| Cost | Lower cost, widely available | Higher cost, more complex processing |

Overview of Thermoplastic Starch and Thermoplastic Cellulose

Thermoplastic starch (TPS) is derived from natural starches through gelatinization, resulting in a biodegradable polymer with excellent film-forming properties, commonly used in packaging applications. Thermoplastic cellulose (TPC), processed by chemically modifying cellulose fibers into a thermoplastic form, offers higher mechanical strength and thermal stability compared to TPS. Both bioplastics are renewable and environmentally friendly, with TPS favored for cost-effectiveness and biodegradability, while TPC is preferred for its durability and versatility in industrial uses.

Chemical Structure and Composition Comparison

Thermoplastic starch (TPS) is primarily composed of amylose and amylopectin molecules, which are polysaccharides derived from natural starch, featuring glucose monomers linked by a-1,4 and a-1,6 glycosidic bonds. Thermoplastic cellulose (TPC) consists of cellulose polymers composed of b-D-glucose units connected by b-1,4-glycosidic bonds, resulting in a highly crystalline and rigid structure. The chemical difference in glycosidic bond type and polymer crystallinity directly influences their thermal processing behavior and mechanical properties in bioplastic applications.

Sources and Raw Material Extraction

Thermoplastic starch is derived primarily from abundant and renewable plant sources such as corn, potato, and tapioca, where starch extraction involves wet milling or enzymatic hydrolysis to obtain the polysaccharide granules. Thermoplastic cellulose originates from lignocellulosic biomass including wood pulp, cotton, and agricultural residues, with raw material extraction utilizing processes like chemical pulping, mechanical refining, or solvent-based dissolution to isolate cellulose fibers. The sustainable sourcing of both thermoplastic starch and cellulose highlights their potential in reducing dependency on petrochemical plastics through efficient biomass conversion techniques.

Biodegradability and Environmental Impact

Thermoplastic starch (TPS) and thermoplastic cellulose (TPC) exhibit distinct biodegradability profiles, with TPS typically degrading faster due to its polysaccharide composition that readily breaks down in soil and compost environments. TPC offers enhanced mechanical strength and durability but may require longer periods to biodegrade, influenced by factors such as crystallinity and degree of polymerization. Both materials contribute positively to reducing environmental impact by lowering dependency on petroleum-based plastics and offering renewable, compostable alternatives that reduce long-term pollution.

Mechanical and Physical Properties

Thermoplastic starch exhibits lower tensile strength and flexibility compared to thermoplastic cellulose, making it more brittle and less durable under mechanical stress. Thermoplastic cellulose offers superior mechanical properties such as higher tensile strength, elongation at break, and improved resistance to moisture absorption due to its crystalline structure. Both materials are biodegradable, but thermoplastic cellulose's enhanced physical properties make it more suitable for applications requiring durability and mechanical robustness.

Processing Techniques and Manufacturing Methods

Thermoplastic starch (TPS) is processed primarily through extrusion and injection molding, where starch is plasticized using water, glycerol, or other plasticizers under heat and shear to produce flexible biodegradable materials. Thermoplastic cellulose (TPC) involves dissolving cellulose in solvents or using chemical modifications before processing via solvent casting, extrusion, or compression molding to enhance mechanical properties and water resistance. TPS manufacturing focuses on rapid gelatinization and moisture control, while TPC requires solvent recovery systems and precise temperature control to maintain cellulose integrity during production.

Applications in Bioplastic Industry

Thermoplastic starch (TPS) is widely utilized in packaging films, disposable items, and agricultural mulch films due to its biodegradability and cost-effectiveness. Thermoplastic cellulose (TPC) offers enhanced mechanical strength and moisture resistance, making it suitable for durable packaging, textile fibers, and automotive components. Both materials contribute to sustainable bioplastic solutions, with TPS favored for short-term, biodegradable applications and TPC for long-lasting, high-performance uses.

Cost Analysis and Market Availability

Thermoplastic starch (TPS) generally offers lower production costs compared to thermoplastic cellulose (TPC) due to the abundance and low cost of starch feedstocks, making TPS more attractive for large-scale applications. Market availability of TPS is higher, with numerous suppliers and established manufacturing processes, while TPC remains limited due to more complex extraction and modification processes from cellulose sources. Cost analysis reveals TPS benefits from cheaper raw materials and simpler processing, whereas TPC commands higher prices tied to specialized production methods and niche market demand.

Performance in Various Environmental Conditions

Thermoplastic starch exhibits high biodegradability but tends to degrade rapidly in humid and wet environments, limiting its long-term performance under moisture exposure. Thermoplastic cellulose offers superior mechanical strength and stability across a broader range of temperatures and humidity levels, enhancing its durability in diverse environmental conditions. Both materials' environmental performance depends on their molecular structure, with cellulose-based bioplastics maintaining integrity better in fluctuating climates.

Future Prospects and Innovations in Bioplastics

Thermoplastic starch (TPS) and thermoplastic cellulose (TPC) exhibit distinct future prospects in bioplastics, with TPS favored for its biodegradability and cost-effectiveness in packaging, while TPC offers superior mechanical strength and thermal stability for advanced applications. Innovations in enzymatic modification and nanocomposite integration enhance TPS performance, expanding its use in flexible films and disposable items. Concurrently, developments in cellulose nanofibers and chemical grafting improve TPC's durability and functional properties, positioning it as a sustainable alternative in automotive and construction industries.

Thermoplastic starch vs Thermoplastic cellulose Infographic

materialdif.com

materialdif.com