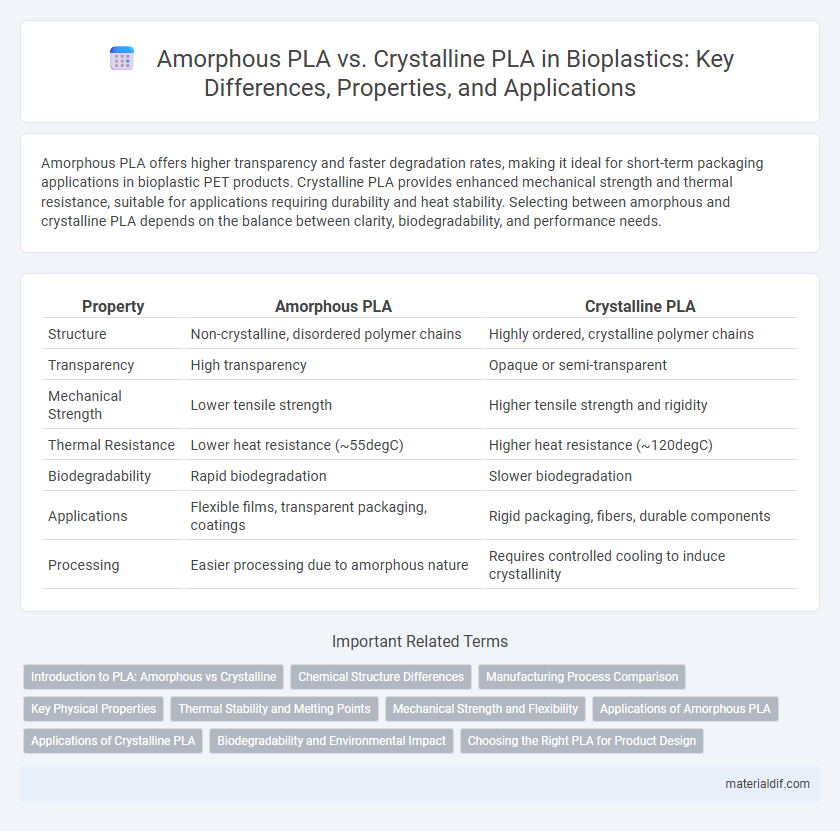

Amorphous PLA offers higher transparency and faster degradation rates, making it ideal for short-term packaging applications in bioplastic PET products. Crystalline PLA provides enhanced mechanical strength and thermal resistance, suitable for applications requiring durability and heat stability. Selecting between amorphous and crystalline PLA depends on the balance between clarity, biodegradability, and performance needs.

Table of Comparison

| Property | Amorphous PLA | Crystalline PLA |

|---|---|---|

| Structure | Non-crystalline, disordered polymer chains | Highly ordered, crystalline polymer chains |

| Transparency | High transparency | Opaque or semi-transparent |

| Mechanical Strength | Lower tensile strength | Higher tensile strength and rigidity |

| Thermal Resistance | Lower heat resistance (~55degC) | Higher heat resistance (~120degC) |

| Biodegradability | Rapid biodegradation | Slower biodegradation |

| Applications | Flexible films, transparent packaging, coatings | Rigid packaging, fibers, durable components |

| Processing | Easier processing due to amorphous nature | Requires controlled cooling to induce crystallinity |

Introduction to PLA: Amorphous vs Crystalline

Amorphous PLA exhibits a transparent, flexible structure with lower melting points, making it ideal for applications requiring clarity and ease of processing. Crystalline PLA features a more ordered molecular arrangement, resulting in higher thermal resistance and mechanical strength suitable for durable products. Understanding the distinct thermal and physical properties of amorphous versus crystalline PLA enables optimized selection for specific biodegradable plastic applications.

Chemical Structure Differences

Amorphous PLA features a disordered molecular arrangement with randomly oriented polymer chains, resulting in lower density and flexibility. In contrast, Crystalline PLA exhibits highly ordered, tightly packed polymer chains that increase rigidity and thermal resistance. The differences in chemical structure impact mechanical properties, with crystalline regions contributing to higher melting points and enhanced strength.

Manufacturing Process Comparison

Amorphous PLA is produced through rapid cooling, which prevents the formation of ordered crystalline regions, resulting in a transparent and less brittle material. Crystalline PLA involves controlled cooling or annealing during the manufacturing process, promoting the development of tightly packed polymer chains that enhance mechanical strength and thermal resistance. The choice between amorphous and crystalline PLA manufacturing methods impacts the final product's durability, clarity, and suitability for specific applications.

Key Physical Properties

Amorphous PLA exhibits lower density and tensile strength compared to crystalline PLA, which offers enhanced mechanical rigidity and higher melting temperature around 170degC. Crystalline PLA's increased crystallinity results in improved barrier properties and thermal resistance, making it suitable for applications requiring durability and heat tolerance. Amorphous PLA's clarity and faster degradation rates favor packaging uses where transparency and compostability are prioritized.

Thermal Stability and Melting Points

Amorphous PLA exhibits a lower melting point around 150-160degC and reduced thermal stability due to its disordered molecular structure, making it more suitable for applications requiring flexibility and transparency. Crystalline PLA demonstrates higher melting points near 170-180degC and improved thermal stability, attributed to its ordered molecular arrangement, which enhances rigidity and heat resistance. These thermal characteristics influence processing temperatures and end-use performance in biodegradable packaging and medical devices.

Mechanical Strength and Flexibility

Amorphous PLA exhibits higher flexibility due to its less ordered molecular structure, making it suitable for applications requiring impact resistance and bendability. Crystalline PLA offers superior mechanical strength and thermal stability, attributed to its densely packed polymer chains, ideal for load-bearing and rigid component manufacturing. The choice between amorphous and crystalline PLA depends on balancing the need for toughness versus structural integrity in bioplastic products.

Applications of Amorphous PLA

Amorphous PLA is widely used in packaging, medical devices, and 3D printing due to its transparency, flexibility, and faster degradation rate compared to crystalline PLA. Its lower melting temperature and enhanced ductility make it ideal for applications requiring clear, strain-resistant materials like single-use containers and films. Unlike crystalline PLA, amorphous PLA enables better processing for complex shapes and biodegradable consumer goods.

Applications of Crystalline PLA

Crystalline PLA exhibits enhanced thermal stability and mechanical strength compared to amorphous PLA, making it ideal for applications requiring higher durability such as packaging, 3D printing, and medical implants. Its increased resistance to heat deformation and slower biodegradation rates enable its use in products exposed to elevated temperatures or longer-term use scenarios. These properties position crystalline PLA as a preferred material for rigid containers, fibers, and load-bearing biodegradable components.

Biodegradability and Environmental Impact

Amorphous PLA exhibits faster biodegradability due to its less ordered molecular structure, allowing microbes to break it down more efficiently in composting environments. In contrast, Crystalline PLA, with higher crystallinity, resists microbial degradation, resulting in slower decomposition rates and prolonged environmental persistence. Therefore, selecting Amorphous PLA supports reduced environmental impact through enhanced compostability and accelerated carbon cycling in sustainable waste management systems.

Choosing the Right PLA for Product Design

Amorphous PLA offers greater transparency and flexibility, making it ideal for applications requiring clear packaging or complex shapes. Crystalline PLA provides enhanced mechanical strength, thermal resistance, and durability, suited for products exposed to higher temperatures or mechanical stress. Selecting the right PLA depends on balancing aesthetic requirements with performance needs in the final product design.

Amorphous PLA vs Crystalline PLA Infographic

materialdif.com

materialdif.com