Bio-PE and Bio-PET are two prominent bioplastics derived from renewable resources, with Bio-PE produced from bioethanol and Bio-PET partially made from bio-based monoethylene glycol. Bio-PE offers excellent chemical resistance and is fully recyclable within conventional polyethylene recycling streams, while Bio-PET combines the durability of PET with a reduced carbon footprint and is widely used in beverage bottles. Both materials provide sustainable alternatives to fossil-fuel-based plastics, but selection depends on specific application requirements like barrier properties and mechanical strength.

Table of Comparison

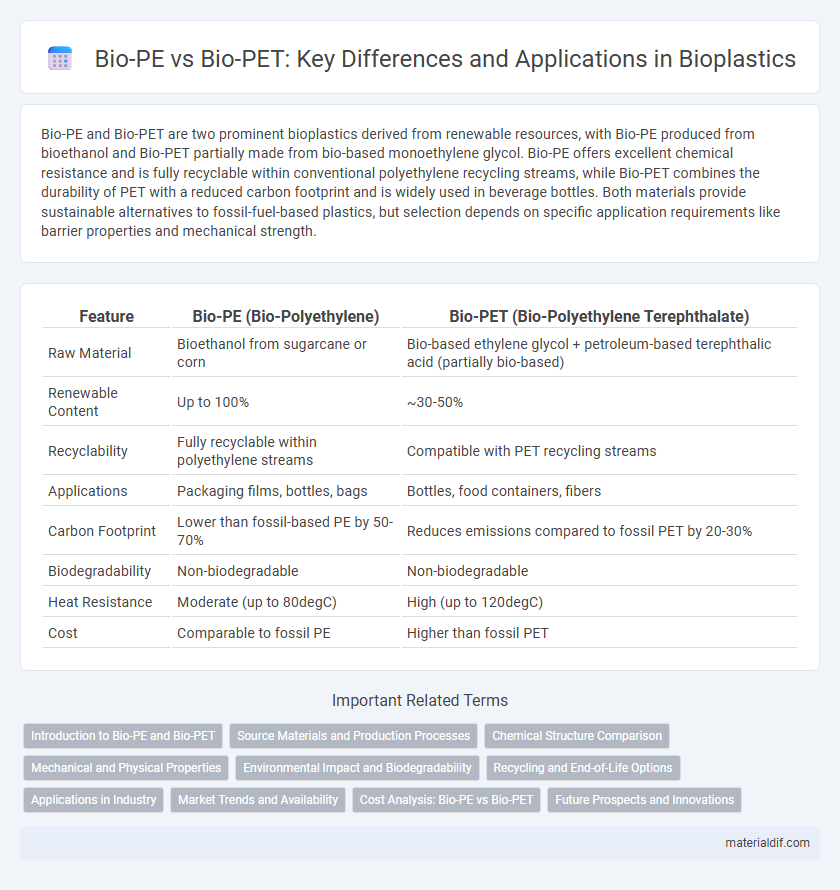

| Feature | Bio-PE (Bio-Polyethylene) | Bio-PET (Bio-Polyethylene Terephthalate) |

|---|---|---|

| Raw Material | Bioethanol from sugarcane or corn | Bio-based ethylene glycol + petroleum-based terephthalic acid (partially bio-based) |

| Renewable Content | Up to 100% | ~30-50% |

| Recyclability | Fully recyclable within polyethylene streams | Compatible with PET recycling streams |

| Applications | Packaging films, bottles, bags | Bottles, food containers, fibers |

| Carbon Footprint | Lower than fossil-based PE by 50-70% | Reduces emissions compared to fossil PET by 20-30% |

| Biodegradability | Non-biodegradable | Non-biodegradable |

| Heat Resistance | Moderate (up to 80degC) | High (up to 120degC) |

| Cost | Comparable to fossil PE | Higher than fossil PET |

Introduction to Bio-PE and Bio-PET

Bio-PE, derived from renewable sources like sugarcane, offers a sustainable alternative to conventional polyethylene with identical chemical properties, ensuring compatibility with existing recycling systems. Bio-PET, produced partially from bio-based ethylene glycol, retains the same durability and clarity as traditional PET, making it suitable for beverage bottles and food packaging. Both bioplastics contribute to reducing fossil fuel dependence and carbon footprint in the packaging industry.

Source Materials and Production Processes

Bio-PE is derived from renewable sugarcane ethanol through a fermentation process that converts sugars into ethylene, while Bio-PET is produced by combining bio-based monoethylene glycol (MEG) derived from bioethanol and terephthalic acid (TPA), which is often petrochemical-based but can also be bio-sourced through biomass fermentation. The production of Bio-PE involves polymerizing bio-ethylene into polyethylene, resulting in a fully bio-based polymer, whereas Bio-PET synthesis requires a chemical reaction between MEG and TPA, producing a polymer with variable bio-based content depending on the TPA source. These differences in raw materials and process complexity influence the sustainability profiles and applications of Bio-PE and Bio-PET in packaging and consumer goods.

Chemical Structure Comparison

Bio-PE (bio-polyethylene) is a long-chain polymer composed of repeating units of ethylene derived from renewable biomass, characterized by its simple hydrocarbon backbone without ester functional groups. Bio-PET (bio-polyethylene terephthalate) features a more complex aromatic polyester structure formed from bio-based ethylene glycol and terephthalic acid, containing ester linkages that provide higher rigidity and thermal stability. The differing chemical structures result in Bio-PE being more flexible and chemically resistant, while Bio-PET offers superior strength and barrier properties for packaging applications.

Mechanical and Physical Properties

Bio-PE exhibits excellent flexibility and impact resistance with a tensile strength ranging from 20 to 30 MPa, making it suitable for packaging films and containers requiring durability and flexibility. Bio-PET offers superior stiffness and higher tensile strength, typically around 55 to 75 MPa, along with better thermal resistance, which is advantageous for bottles and applications needing rigidity and heat resistance. Both bioplastics provide good moisture barrier properties, but Bio-PET outperforms Bio-PE in gas barrier efficiency, important for preserving carbonation and extending shelf life.

Environmental Impact and Biodegradability

Bio-PE, derived from renewable sugarcane ethanol, offers a significantly lower carbon footprint compared to traditional plastics due to its reduced fossil fuel reliance, yet it remains non-biodegradable and requires industrial recycling processes to minimize environmental impact. Bio-PET, partially bio-based through plant-derived monoethylene glycol, maintains the durable properties of conventional PET and offers improved recyclability with established recycling infrastructure but does not biodegrade naturally, posing challenges for end-of-life disposal. Both Bio-PE and Bio-PET contribute to reduced greenhouse gas emissions during production, however, neither material achieves full biodegradability, emphasizing the need for effective waste management and circular economy practices.

Recycling and End-of-Life Options

Bio-PE, derived from renewable ethanol, is mechanically recyclable within existing polyethylene waste streams, enabling efficient circularity without requiring major adjustments in recycling infrastructure. Bio-PET, produced using renewable bio-based monoethylene glycol, benefits from compatibility with conventional PET recycling systems but faces challenges with chemical recycling due to its mixed bio and fossil origin. Both materials support sustainability goals, yet Bio-PE offers more straightforward mechanical recycling, while Bio-PET's end-of-life options include mechanical recycling and emerging chemical depolymerization techniques.

Applications in Industry

Bio-PE, derived from renewable resources such as sugarcane, is widely utilized in packaging, agriculture films, and consumer goods due to its excellent moisture barrier and flexibility. Bio-PET, produced from bio-based ethanol, is predominantly applied in beverage bottles, food containers, and textiles because of its superior clarity, strength, and recyclability. Both bioplastics support sustainability goals but target different industry needs based on their mechanical properties and processing capabilities.

Market Trends and Availability

Bio-PE dominates the bioplastic market due to its compatibility with existing polyethylene infrastructure and lower production costs, driving widespread adoption in packaging and consumer goods. Bio-PET, while offering superior barrier properties and clarity for beverage bottles and food containers, faces higher production costs and limited feedstock availability, slowing its market penetration. Emerging investments in feedstock diversification and recycling technologies aim to increase Bio-PET availability, potentially narrowing the gap with Bio-PE in the next five years.

Cost Analysis: Bio-PE vs Bio-PET

Bio-PE generally presents a lower production cost compared to Bio-PET due to simpler polymerization processes and abundant raw materials derived from sugarcane or corn starch. Bio-PET involves higher expenses associated with both its bio-based ethylene glycol and purified terephthalic acid components, which require more energy-intensive synthesis. Cost competitiveness of Bio-PE enhances its adoption in packaging and agriculture, while Bio-PET's higher price limits its use primarily to premium and niche applications.

Future Prospects and Innovations

Bio-PE is gaining traction due to its compatibility with existing polyethylene recycling streams and renewable feedstocks from sugarcane, positioning it as a sustainable alternative in packaging and agriculture. Bio-PET, derived from plant-based ethylene glycol and TPA precursors, holds promise for widespread use in beverage bottles with advancements targeting full bio-based content and improved biodegradability. Innovations in catalyst development and microbial fermentation are driving both Bio-PE and Bio-PET toward enhanced performance, cost-effectiveness, and circular economy integration.

Bio-PE vs Bio-PET Infographic

materialdif.com

materialdif.com