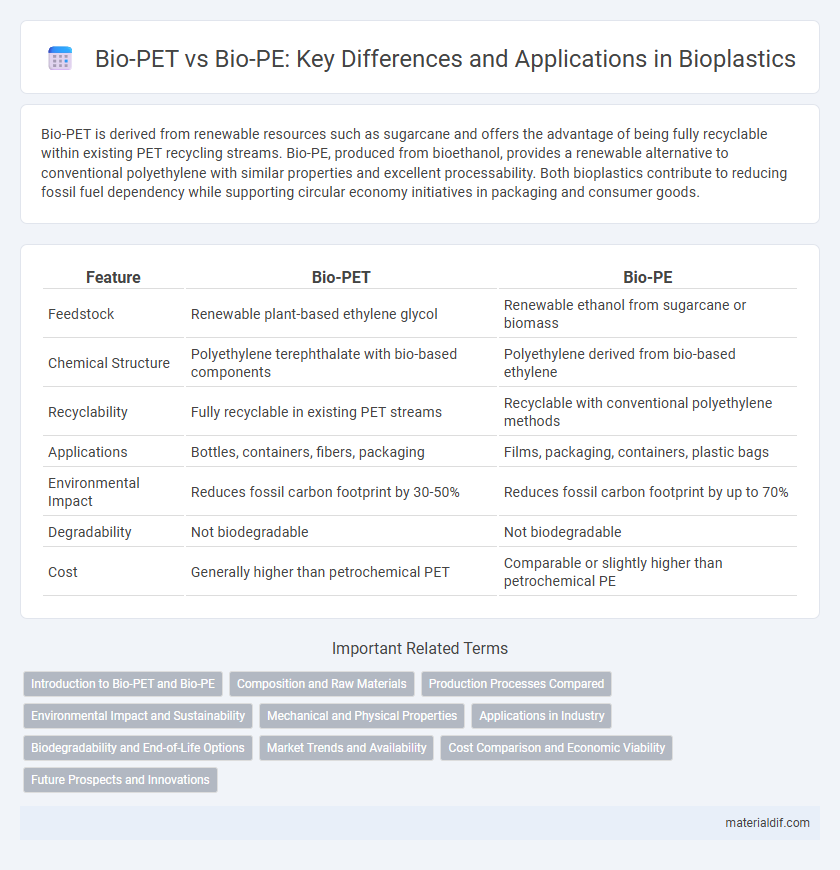

Bio-PET is derived from renewable resources such as sugarcane and offers the advantage of being fully recyclable within existing PET recycling streams. Bio-PE, produced from bioethanol, provides a renewable alternative to conventional polyethylene with similar properties and excellent processability. Both bioplastics contribute to reducing fossil fuel dependency while supporting circular economy initiatives in packaging and consumer goods.

Table of Comparison

| Feature | Bio-PET | Bio-PE |

|---|---|---|

| Feedstock | Renewable plant-based ethylene glycol | Renewable ethanol from sugarcane or biomass |

| Chemical Structure | Polyethylene terephthalate with bio-based components | Polyethylene derived from bio-based ethylene |

| Recyclability | Fully recyclable in existing PET streams | Recyclable with conventional polyethylene methods |

| Applications | Bottles, containers, fibers, packaging | Films, packaging, containers, plastic bags |

| Environmental Impact | Reduces fossil carbon footprint by 30-50% | Reduces fossil carbon footprint by up to 70% |

| Degradability | Not biodegradable | Not biodegradable |

| Cost | Generally higher than petrochemical PET | Comparable or slightly higher than petrochemical PE |

Introduction to Bio-PET and Bio-PE

Bio-PET (Bio-Polyethylene Terephthalate) is a sustainable plastic derived primarily from renewable resources such as sugarcane ethanol, offering identical properties and recyclability to conventional PET used in beverage bottles and packaging. Bio-PE (Bio-Polyethylene) is produced from bioethanol obtained through the fermentation of biomass, providing a renewable alternative to traditional polyethylene with applications in films, containers, and packaging materials. Both Bio-PET and Bio-PE significantly reduce dependence on fossil fuels and lower carbon footprints, making them critical materials in advancing environmentally friendly plastic production.

Composition and Raw Materials

Bio-PET is a partially bio-based polymer derived primarily from renewable plant materials such as sugarcane or corn through the fermentation process, producing bio-based ethylene glycol combined with petroleum-derived terephthalic acid. In contrast, Bio-PE is produced entirely from renewable feedstocks like sugarcane ethanol, resulting in 100% bio-based polyethylene with no petroleum content. The key compositional difference lies in Bio-PET's combination of bio-based and fossil-based monomers versus Bio-PE's purely bio-based polyethylene polymer structure.

Production Processes Compared

Bio-PET is produced through the fermentation of biomass-derived ethylene glycol combined with purified terephthalic acid, whereas Bio-PE is synthesized by polymerizing bioethanol-derived ethylene. The production of Bio-PET involves more complex chemical processes and higher energy consumption due to the requirement for terephthalic acid, while Bio-PE production uses a more straightforward polymerization of ethylene, resulting in lower carbon emissions. Both bioplastics leverage renewable resources, but Bio-PE benefits from simpler feedstock conversion and faster production cycles compared to Bio-PET.

Environmental Impact and Sustainability

Bio-PET, derived partially from renewable resources like sugarcane, offers significant reductions in carbon footprint compared to conventional PET, but its production still relies on fossil fuels for the remaining carbon content. Bio-PE is produced entirely from renewable feedstocks such as sugarcane ethanol, resulting in lower greenhouse gas emissions and enhanced biodegradability potential. Both materials contribute to sustainability, but Bio-PE's fully renewable origin and easier recyclability provide a stronger environmental advantage in reducing plastic pollution and fossil resource dependency.

Mechanical and Physical Properties

Bio-PET exhibits superior mechanical strength and thermal stability compared to Bio-PE, making it ideal for applications requiring rigidity and heat resistance. Bio-PE offers greater flexibility and impact resistance, suitable for products needing durability and pliability. Both bioplastics provide valuable eco-friendly options, with Bio-PET favored in packaging and Bio-PE in flexible films and containers.

Applications in Industry

Bio-PET is predominantly used in the packaging industry, especially for producing bottles and containers due to its excellent barrier properties and recyclability. Bio-PE finds extensive applications in flexible packaging, agricultural films, and consumer goods, benefiting from its high impact resistance and versatility. Both Bio-PET and Bio-PE contribute to sustainable alternatives in automotive parts and electronics, enhancing eco-friendly manufacturing processes across industries.

Biodegradability and End-of-Life Options

Bio-PET, derived partially from renewable resources, is recyclable within existing PET recycling streams but is not biodegradable, requiring mechanical or chemical recycling for end-of-life management. Bio-PE, produced entirely from biological feedstocks like sugarcane, is chemically identical to conventional polyethylene and highly recyclable but also non-biodegradable, relying on recycling or energy recovery after use. Both materials offer sustainable alternatives with specific end-of-life strategies focusing on recycling rather than biodegradation, addressing plastic waste challenges through circular economy solutions.

Market Trends and Availability

Bio-PET dominates the bioplastic market due to its widespread use in packaging and strong recycling infrastructure, accounting for over 70% of global bioplastic resin production. Bio-PE, derived from bioethanol primarily from sugarcane, is gaining traction in markets focused on renewable raw materials and boasts expanding availability, particularly in Brazil and Europe. Market trends indicate increasing investment in Bio-PE production capacity to meet growing demand for sustainable polymers in consumer goods and automotive sectors.

Cost Comparison and Economic Viability

Bio-PET production costs remain higher than Bio-PE due to more complex polymerization processes and reliance on purified terephthalic acid derived from bio-based sources. Bio-PE benefits from established bio-ethanol fermentation infrastructure, enabling more cost-effective scaling and lower feedstock expenses. Economic viability favors Bio-PE in large-volume applications, while Bio-PET's superior barrier properties justify premium pricing in specialty markets.

Future Prospects and Innovations

Bio-PET, derived from renewable resources like sugarcane, offers enhanced recyclability and is increasingly adopted in packaging due to its identical properties to traditional PET, facilitating integration into existing recycling systems. Bio-PE, produced from bioethanol, presents significant potential for seamless substitution in the polyethylene market, with ongoing innovations targeting improved biodegradability and carbon footprint reduction. Future prospects for both bio-based polymers focus on advancing bio-refinery technologies, expanding feedstock diversity, and developing hybrid materials to boost performance and sustainability in various industrial applications.

Bio-PET vs Bio-PE Infographic

materialdif.com

materialdif.com