Cold-rolled aluminum offers a smoother surface finish and tighter tolerances compared to hot-rolled aluminum, making it ideal for applications requiring precision and aesthetic appeal. Hot-rolled aluminum is typically more cost-effective and has greater ductility, suitable for structural components where strength and formability are prioritized. Choosing between cold-rolled and hot-rolled aluminum depends on the specific demands of the project, balancing factors like mechanical properties, surface quality, and budget.

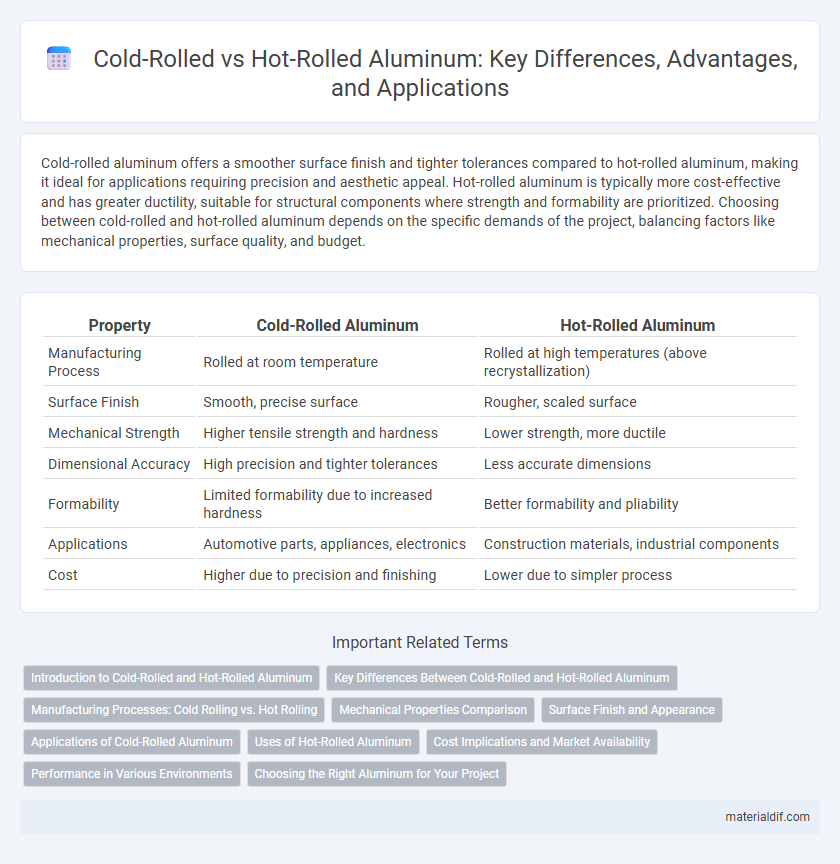

Table of Comparison

| Property | Cold-Rolled Aluminum | Hot-Rolled Aluminum |

|---|---|---|

| Manufacturing Process | Rolled at room temperature | Rolled at high temperatures (above recrystallization) |

| Surface Finish | Smooth, precise surface | Rougher, scaled surface |

| Mechanical Strength | Higher tensile strength and hardness | Lower strength, more ductile |

| Dimensional Accuracy | High precision and tighter tolerances | Less accurate dimensions |

| Formability | Limited formability due to increased hardness | Better formability and pliability |

| Applications | Automotive parts, appliances, electronics | Construction materials, industrial components |

| Cost | Higher due to precision and finishing | Lower due to simpler process |

Introduction to Cold-Rolled and Hot-Rolled Aluminum

Cold-rolled aluminum undergoes rolling at room temperature, resulting in a smoother surface finish, higher strength, and tighter dimensional tolerances compared to hot-rolled aluminum. Hot-rolled aluminum is processed at high temperatures above its recrystallization point, which enhances its workability and produces a more coarse surface texture. Both methods affect aluminum's mechanical properties and surface characteristics, making them suited for specific industrial applications such as automotive parts, construction materials, and packaging.

Key Differences Between Cold-Rolled and Hot-Rolled Aluminum

Cold-rolled aluminum undergoes processing at room temperature, resulting in a smoother surface finish, tighter tolerances, and improved strength due to strain hardening. Hot-rolled aluminum is processed at high temperatures, allowing for easier shaping and larger structural components but usually features a rougher surface and looser dimensional tolerances. The choice between cold-rolled and hot-rolled aluminum depends on specific application requirements such as surface quality, mechanical properties, and fabrication complexity.

Manufacturing Processes: Cold Rolling vs. Hot Rolling

Cold-rolled aluminum undergoes deformation at or near room temperature, resulting in a smoother surface finish, higher strength, and tighter dimensional tolerances compared to hot-rolled aluminum. Hot-rolled aluminum is processed at temperatures above its recrystallization point, allowing easier shaping but producing a rougher surface and less precise dimensions. The choice between cold rolling and hot rolling significantly impacts mechanical properties, surface quality, and suitability for specific industrial applications.

Mechanical Properties Comparison

Cold-rolled aluminum exhibits higher tensile strength and improved surface finish compared to hot-rolled aluminum due to strain hardening during the rolling process. Hot-rolled aluminum shows better ductility and is more suitable for applications requiring extensive forming and shaping. The choice between these two depends on balancing the need for strength versus formability in specific engineering applications.

Surface Finish and Appearance

Cold-rolled aluminum features a smoother, more polished surface finish due to the controlled rolling at room temperature, making it ideal for applications requiring high aesthetic quality. Hot-rolled aluminum exhibits a rougher, matte surface with scale marks resulting from high-temperature processing, which is less visually refined but offers greater formability. The distinctive surface textures influence their suitability for decorative uses and coating adhesion in industries such as automotive and construction.

Applications of Cold-Rolled Aluminum

Cold-rolled aluminum is extensively used in applications requiring precise dimensions and superior surface finish, such as automotive panels, aerospace components, and packaging materials. Its enhanced mechanical properties and improved strength-to-weight ratio make it ideal for manufacturing durable and lightweight products. The fine surface texture also supports coating and painting processes, increasing the material's versatility in decorative and functional applications.

Uses of Hot-Rolled Aluminum

Hot-rolled aluminum is commonly used in applications requiring strong structural components such as construction beams, automotive parts, and heavy machinery due to its enhanced durability and workability. Its surface texture is coarser compared to cold-rolled aluminum, making it suitable for products where surface finish is less critical but strength and toughness are prioritized. Industries such as aerospace and transportation rely on hot-rolled aluminum for manufacturing chassis, panels, and framing components needing high mechanical performance.

Cost Implications and Market Availability

Cold-rolled aluminum typically incurs higher production costs due to the additional processing steps that improve surface finish and dimensional accuracy, resulting in a more expensive product compared to hot-rolled aluminum. Hot-rolled aluminum offers greater market availability and lower prices, making it a preferred choice for applications where cost efficiency and volume are critical. The cost implications and market dynamics influence the selection of aluminum type based on project budgets and supply chain demands.

Performance in Various Environments

Cold-rolled aluminum exhibits superior surface finish and dimensional precision, making it ideal for environments requiring corrosion resistance and aesthetic appeal, such as architectural applications. Hot-rolled aluminum offers enhanced mechanical strength and toughness, performing better in high-temperature or heavy-load industrial settings. The choice depends on environmental demands, with cold-rolled favored for controlled conditions and hot-rolled suited for rugged, fluctuating temperatures.

Choosing the Right Aluminum for Your Project

Cold-rolled aluminum offers superior surface finish, tighter tolerances, and increased strength, making it ideal for applications requiring precision and aesthetic appeal. Hot-rolled aluminum, characterized by thicker gauges and a rougher surface, suits structural projects where dimensional accuracy is less critical. Selecting the right aluminum depends on project requirements like strength, surface quality, and fabrication processes.

Cold-Rolled Aluminum vs Hot-Rolled Aluminum Infographic

materialdif.com

materialdif.com