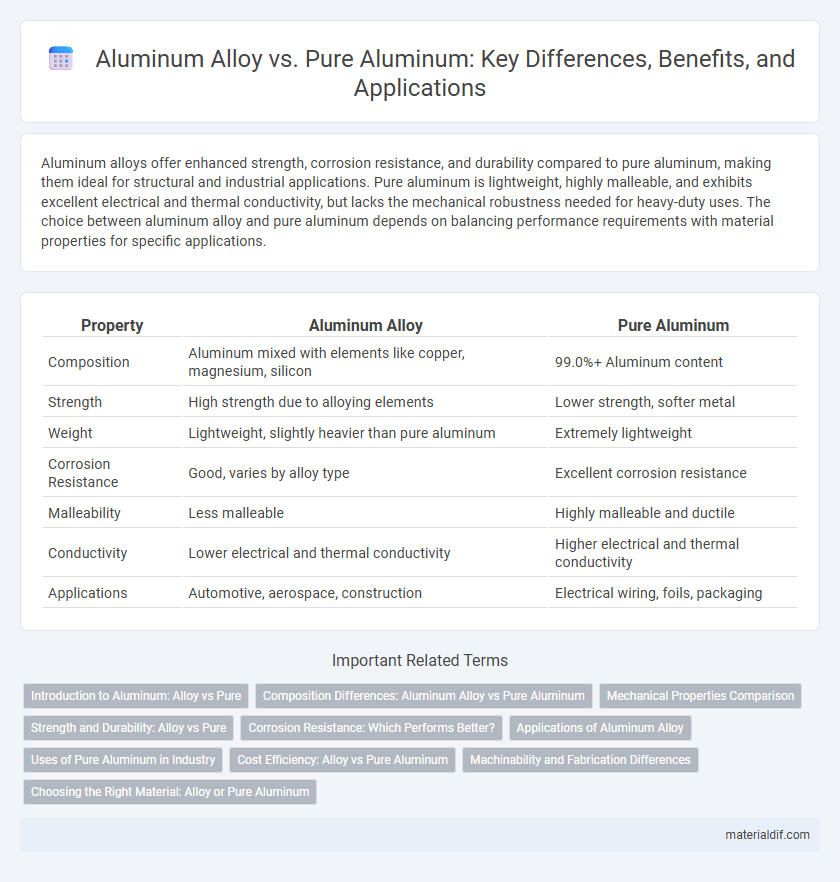

Aluminum alloys offer enhanced strength, corrosion resistance, and durability compared to pure aluminum, making them ideal for structural and industrial applications. Pure aluminum is lightweight, highly malleable, and exhibits excellent electrical and thermal conductivity, but lacks the mechanical robustness needed for heavy-duty uses. The choice between aluminum alloy and pure aluminum depends on balancing performance requirements with material properties for specific applications.

Table of Comparison

| Property | Aluminum Alloy | Pure Aluminum |

|---|---|---|

| Composition | Aluminum mixed with elements like copper, magnesium, silicon | 99.0%+ Aluminum content |

| Strength | High strength due to alloying elements | Lower strength, softer metal |

| Weight | Lightweight, slightly heavier than pure aluminum | Extremely lightweight |

| Corrosion Resistance | Good, varies by alloy type | Excellent corrosion resistance |

| Malleability | Less malleable | Highly malleable and ductile |

| Conductivity | Lower electrical and thermal conductivity | Higher electrical and thermal conductivity |

| Applications | Automotive, aerospace, construction | Electrical wiring, foils, packaging |

Introduction to Aluminum: Alloy vs Pure

Aluminum alloys contain additional elements such as copper, magnesium, and zinc, enhancing strength, corrosion resistance, and machinability compared to pure aluminum, which is lightweight and highly malleable but relatively soft. Pure aluminum, typically 99.0% or higher in purity, is ideal for applications requiring excellent conductivity and corrosion resistance, whereas aluminum alloys are preferred for structural and industrial uses due to their superior mechanical properties. Common aluminum alloys include 6061 and 7075, widely used in aerospace, automotive, and construction industries for their optimized balance of strength and durability.

Composition Differences: Aluminum Alloy vs Pure Aluminum

Aluminum alloys consist of aluminum combined with elements such as copper, magnesium, silicon, and zinc, enhancing strength, corrosion resistance, and machinability compared to pure aluminum. Pure aluminum typically contains 99.0% or higher aluminum content, offering excellent ductility, electrical conductivity, and corrosion resistance but lower mechanical strength. The specific composition ratios in alloys determine performance properties tailored for applications in aerospace, automotive, and construction industries.

Mechanical Properties Comparison

Aluminum alloys exhibit significantly higher tensile strength and improved hardness compared to pure aluminum, making them ideal for structural applications requiring durability. Pure aluminum boasts superior ductility and corrosion resistance but lacks the mechanical robustness found in alloys. The addition of elements like copper, magnesium, and silicon in aluminum alloys enhances fatigue resistance and yield strength, optimizing performance for demanding engineering uses.

Strength and Durability: Alloy vs Pure

Aluminum alloys exhibit significantly higher strength and improved durability compared to pure aluminum due to the presence of additional elements such as copper, magnesium, and silicon. These alloying elements enhance mechanical properties by increasing hardness, tensile strength, and resistance to wear and corrosion, making alloys ideal for structural and industrial applications. Pure aluminum offers excellent corrosion resistance and flexibility but lacks the robust strength required for heavy-load or high-stress environments.

Corrosion Resistance: Which Performs Better?

Aluminum alloys generally outperform pure aluminum in corrosion resistance due to the addition of elements like magnesium, silicon, and zinc, which enhance the formation of a stable, protective oxide layer. While pure aluminum naturally develops a thin oxide film that shields it from corrosion, certain alloys offer improved resistance to specific environments, such as seawater or industrial atmospheres. Selecting the appropriate aluminum alloy based on environmental exposure ensures better durability and longevity compared to relying on pure aluminum alone.

Applications of Aluminum Alloy

Aluminum alloys are preferred in aerospace, automotive, and construction industries due to their enhanced strength, corrosion resistance, and lightweight properties compared to pure aluminum. These alloys, such as 6061 and 7075, provide superior mechanical performance, making them ideal for structural components, aircraft frames, and high-performance automotive parts. Their adaptability and durability enable diverse applications where pure aluminum's softness and lower strength would be insufficient.

Uses of Pure Aluminum in Industry

Pure aluminum is widely used in the electrical industry due to its excellent conductivity and lightweight properties, making it ideal for wiring and electrical components. It is also employed in packaging applications, such as aluminum foil and beverage cans, where corrosion resistance and malleability are critical. Manufacturing processes benefit from pure aluminum's softness, allowing it to be easily formed into sheets and foils for various industrial uses.

Cost Efficiency: Alloy vs Pure Aluminum

Aluminum alloys offer enhanced cost efficiency compared to pure aluminum due to their superior mechanical properties, which allow for reduced material usage and longer component lifespans. While pure aluminum is less expensive per pound, alloys' improved strength and durability lower overall production and maintenance costs in applications such as automotive and aerospace industries. The initial higher cost of aluminum alloys is offset by their performance benefits and extended service intervals, driving better long-term economic value.

Machinability and Fabrication Differences

Aluminum alloys exhibit improved machinability compared to pure aluminum due to the presence of alloying elements such as copper, magnesium, and silicon, which enhance hardness and reduce ductility, enabling more precise cutting and shaping. Pure aluminum, while highly malleable and ductile, tends to be softer and prone to galling during machining, making it less suitable for complex fabrication processes. Fabrication of aluminum alloys often involves heat treatment techniques that optimize strength and machinability, whereas pure aluminum is typically shaped through cold working and annealing to maintain its form and surface finish.

Choosing the Right Material: Alloy or Pure Aluminum

Aluminum alloys offer enhanced strength, corrosion resistance, and durability compared to pure aluminum, making them ideal for structural and automotive applications. Pure aluminum, with its excellent conductivity and malleability, is preferred for electrical components and applications requiring high thermal efficiency. Selecting between aluminum alloy and pure aluminum depends on specific project requirements such as mechanical strength, corrosion resistance, and weight considerations.

Aluminum Alloy vs Pure Aluminum Infographic

materialdif.com

materialdif.com