Mill finish aluminum features a smooth, raw surface directly from the extrusion or rolling process, offering a cost-effective and functional option without additional treatment. Brushed finish aluminum undergoes a mechanical abrasion that creates fine lines on the surface, enhancing its aesthetic appeal while also improving scratch resistance. Choosing between mill finish and brushed finish depends on the desired look, application, and budget for aluminum pet projects.

Table of Comparison

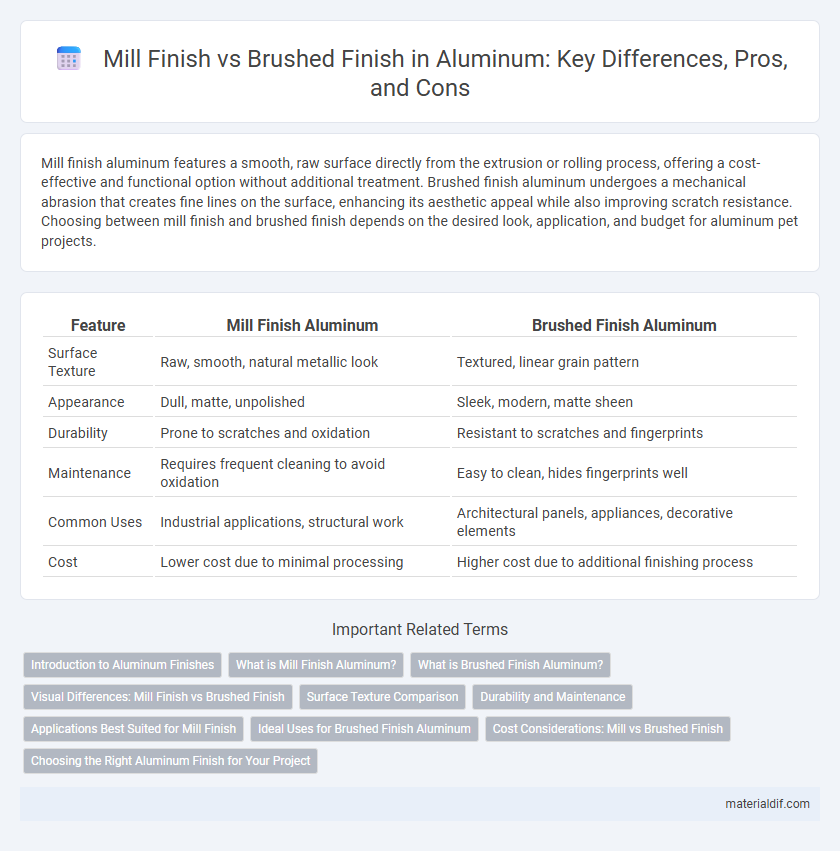

| Feature | Mill Finish Aluminum | Brushed Finish Aluminum |

|---|---|---|

| Surface Texture | Raw, smooth, natural metallic look | Textured, linear grain pattern |

| Appearance | Dull, matte, unpolished | Sleek, modern, matte sheen |

| Durability | Prone to scratches and oxidation | Resistant to scratches and fingerprints |

| Maintenance | Requires frequent cleaning to avoid oxidation | Easy to clean, hides fingerprints well |

| Common Uses | Industrial applications, structural work | Architectural panels, appliances, decorative elements |

| Cost | Lower cost due to minimal processing | Higher cost due to additional finishing process |

Introduction to Aluminum Finishes

Mill finish aluminum is the natural state of aluminum after it is rolled or extruded, featuring a dull, matte surface prone to slight oxidation and minor imperfections. Brushed finish aluminum undergoes an abrasive process that creates a uniform, linear texture, enhancing both aesthetic appeal and scratch resistance. Choosing between mill and brushed finishes depends on the desired look, surface durability, and application requirements for aluminum products.

What is Mill Finish Aluminum?

Mill finish aluminum refers to the natural surface of aluminum after it has been extruded or rolled, without any additional surface treatment or coating. This finish often appears dull and slightly rough due to the oxidation layer formed during manufacturing, making it more prone to corrosion if left unprotected. Mill finish aluminum is commonly used for industrial applications where further processing, such as anodizing or painting, will be applied to enhance durability and appearance.

What is Brushed Finish Aluminum?

Brushed finish aluminum features a unidirectional satin finish achieved by polishing the metal surface with an abrasive belt or brush, creating fine parallel lines that enhance its texture and appearance. This finish improves the material's resistance to corrosion and abrasion while offering a modern, sleek look ideal for architectural and decorative applications. Unlike mill finish aluminum, which has a raw, unfinished surface directly from the rolling process, brushed finish aluminum offers greater aesthetic appeal and improved durability in both indoor and outdoor environments.

Visual Differences: Mill Finish vs Brushed Finish

Mill finish aluminum features a raw, matte surface with visible tooling marks and a slightly rough texture, giving it an industrial, unfinished appearance. Brushed finish aluminum displays fine, uniform linear scratches created by abrasive polishing, resulting in a smooth, satin-like surface that reduces glare and enhances aesthetic appeal. These visual differences affect both the reflectivity and tactile experience, making mill finish ideal for utilitarian purposes and brushed finish preferred for decorative applications.

Surface Texture Comparison

Mill finish aluminum features a smooth, slightly matte surface resulting from the extrusion or rolling process, retaining natural oxide layers that provide basic corrosion resistance. Brushed finish aluminum exhibits a uniform, directional grain texture created by abrasive brushing techniques, enhancing aesthetic appeal while improving scratch resistance and reducing glare. The brushed surface's micro-grooves increase surface roughness compared to the mill finish, making it ideal for architectural and decorative applications.

Durability and Maintenance

Mill finish aluminum features a raw, untreated surface that is more prone to oxidation and corrosion over time, requiring frequent cleaning and protective coatings to maintain durability. Brushed finish aluminum undergoes a mechanical polishing process, resulting in a textured surface that better resists scratches and tarnishing, reducing maintenance needs. The enhanced durability and lower upkeep of brushed finish make it ideal for high-traffic or outdoor applications where longevity is critical.

Applications Best Suited for Mill Finish

Mill finish aluminum, characterized by its natural, untreated surface, is ideally suited for applications requiring corrosion resistance and cost efficiency, such as HVAC components, window frames, and automotive parts. Its raw appearance ensures optimal paint adhesion, making it perfect for products that will undergo further finishing processes like anodizing or powder coating. Mill finish aluminum is preferable in industrial and architectural projects where functionality and preparation for secondary treatments outweigh aesthetic considerations.

Ideal Uses for Brushed Finish Aluminum

Brushed finish aluminum features a textured surface with fine, linear scratches that enhance its aesthetic appeal and hide fingerprints and minor imperfections, making it ideal for decorative applications such as architectural panels, kitchen appliances, and consumer electronics. Its durability and subtle sheen are well-suited for both indoor and outdoor use where a modern, industrial look is desired without compromising corrosion resistance. This finish is particularly favored in environments requiring moderate wear resistance and easy maintenance, including automotive trims and elevator interiors.

Cost Considerations: Mill vs Brushed Finish

Mill finish aluminum typically costs less due to minimal processing, making it an economical choice for large-scale projects or budget-sensitive applications. Brushed finish aluminum involves additional machining and polishing steps, increasing labor and production time, which raises the overall material cost. Choosing between mill and brushed finishes depends on balancing aesthetic requirements with budget constraints, as the brushed finish provides a premium look at a higher price.

Choosing the Right Aluminum Finish for Your Project

Mill finish aluminum features a raw, untreated surface that showcases the natural metallic texture, making it cost-effective for applications where appearance is not a priority. Brushed finish aluminum offers a smooth, satin-like surface with fine, linear scratches that enhance both aesthetics and corrosion resistance, ideal for architectural and decorative projects. Selecting the appropriate finish depends on factors like environmental exposure, desired visual appeal, and budget constraints.

Mill Finish vs Brushed Finish Infographic

materialdif.com

materialdif.com