Rolled aluminum offers a lightweight option with excellent surface finish and uniform thickness, making it ideal for applications requiring precision and corrosion resistance. Forged aluminum provides superior strength and structural integrity due to its dense grain structure, which is beneficial in high-stress environments. Choosing between rolled and forged aluminum depends on the specific performance requirements and load-bearing conditions of the aluminum pet components.

Table of Comparison

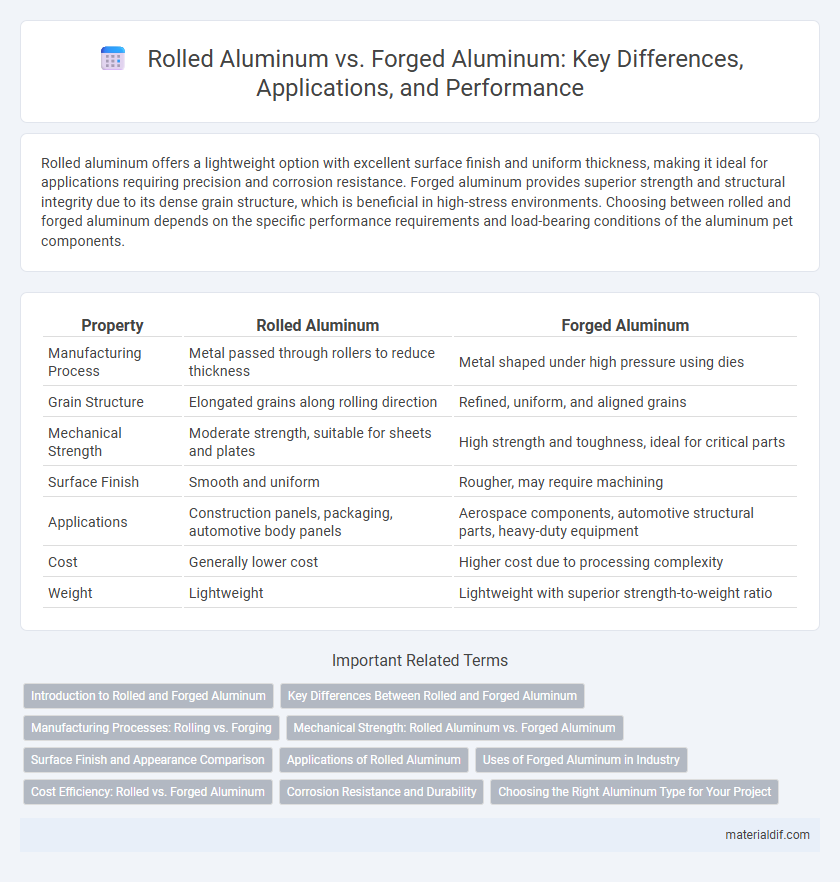

| Property | Rolled Aluminum | Forged Aluminum |

|---|---|---|

| Manufacturing Process | Metal passed through rollers to reduce thickness | Metal shaped under high pressure using dies |

| Grain Structure | Elongated grains along rolling direction | Refined, uniform, and aligned grains |

| Mechanical Strength | Moderate strength, suitable for sheets and plates | High strength and toughness, ideal for critical parts |

| Surface Finish | Smooth and uniform | Rougher, may require machining |

| Applications | Construction panels, packaging, automotive body panels | Aerospace components, automotive structural parts, heavy-duty equipment |

| Cost | Generally lower cost | Higher cost due to processing complexity |

| Weight | Lightweight | Lightweight with superior strength-to-weight ratio |

Introduction to Rolled and Forged Aluminum

Rolled aluminum is produced by passing aluminum slabs through rollers to reduce thickness and enhance surface finish, resulting in sheet, plate, or foil forms ideal for applications requiring uniform thickness and smooth surfaces. Forged aluminum is shaped by applying localized compressive forces using dies and hammers, creating components with superior strength and grain structure, often used in aerospace and automotive industries. Both manufacturing processes influence aluminum's mechanical properties and suitability for specific engineering requirements.

Key Differences Between Rolled and Forged Aluminum

Rolled aluminum is produced by passing heated aluminum slabs through rollers to achieve thin sheets with uniform thickness and smooth surfaces, making it ideal for applications requiring precise dimensions and high surface quality. Forged aluminum involves shaping aluminum by applying compressive forces with a hammer or press, resulting in components with superior structural integrity, grain alignment, and mechanical strength. Key differences include rolled aluminum's flat, thin form suited for sheet products versus forged aluminum's dense, shaped form optimized for high-strength parts like aircraft components and automotive parts.

Manufacturing Processes: Rolling vs. Forging

Rolled aluminum undergoes a continuous deformation process where aluminum slabs are passed through rollers to achieve desired thickness and surface finish, optimizing grain structure for enhanced strength and uniformity. Forged aluminum is shaped by applying compressive forces through dies or hammers, producing components with refined grain flow and superior mechanical properties suitable for high-stress applications. Rolling allows for large-scale production with consistent dimensions, while forging offers improved structural integrity and resistance to fatigue due to grain alignment.

Mechanical Strength: Rolled Aluminum vs. Forged Aluminum

Forged aluminum typically exhibits superior mechanical strength compared to rolled aluminum due to its dense grain structure formed under high pressure, enhancing toughness and fatigue resistance. Rolled aluminum, while strong and lightweight, often has a more uniform grain orientation that provides good tensile strength but may be less resistant to impact and stress than forged counterparts. Engineers select forged aluminum for critical applications requiring maximum durability, whereas rolled aluminum is favored for its cost-effectiveness and ease of fabrication in less demanding contexts.

Surface Finish and Appearance Comparison

Rolled aluminum typically features a smoother, more uniform surface finish due to the continuous pressure applied during the rolling process, making it ideal for applications requiring refined aesthetics. Forged aluminum often exhibits a more textured and varied surface appearance, which can enhance grip or provide a distinctive look but may require additional machining or finishing for a polished appearance. The choice between rolled and forged aluminum depends on the desired surface quality, with rolled aluminum favored for sleek, consistent finishes and forged aluminum preferred for strength combined with a rustic or functional texture.

Applications of Rolled Aluminum

Rolled aluminum is extensively used in automotive manufacturing, aerospace components, and packaging due to its excellent formability and lightweight properties. Its ability to produce thin sheets and foils makes it ideal for creating car body panels, aircraft skins, and food and beverage cans. The material's high strength-to-weight ratio and corrosion resistance further enhance its suitability for structural and decorative applications.

Uses of Forged Aluminum in Industry

Forged aluminum is extensively used in the aerospace, automotive, and marine industries due to its superior strength and durability compared to rolled aluminum. Its ability to withstand high stress makes it ideal for critical components such as aircraft fittings, engine parts, and high-performance automotive wheels. The forging process enhances grain structure, resulting in improved mechanical properties essential for demanding industrial applications.

Cost Efficiency: Rolled vs. Forged Aluminum

Rolled aluminum offers greater cost efficiency compared to forged aluminum due to lower production costs and faster manufacturing processes, making it ideal for large-scale applications. Forged aluminum, while stronger and more durable, involves more expensive tooling and labor-intensive production, increasing overall expenses. Selecting rolled aluminum can significantly reduce material and processing costs without sacrificing essential strength for many structural uses.

Corrosion Resistance and Durability

Rolled aluminum exhibits enhanced corrosion resistance due to its uniform grain structure, which minimizes surface defects and oxidation. Forged aluminum offers superior durability by exhibiting increased strength and toughness resulting from its dense, compact metal composition. Both processes improve aluminum's performance, but rolled aluminum excels in applications requiring resistance to environmental degradation, while forged aluminum is preferable for high-stress, impact-resistant components.

Choosing the Right Aluminum Type for Your Project

Rolled aluminum offers excellent surface finish and uniform strength, making it ideal for applications requiring precise dimensions and good formability such as automotive panels and packaging. Forged aluminum provides superior mechanical properties and enhanced fatigue resistance, suitable for high-stress components like aerospace parts and structural elements. Selecting the right aluminum type depends on balancing factors such as required strength, surface finish, and production volume specific to your project needs.

Rolled Aluminum vs Forged Aluminum Infographic

materialdif.com

materialdif.com