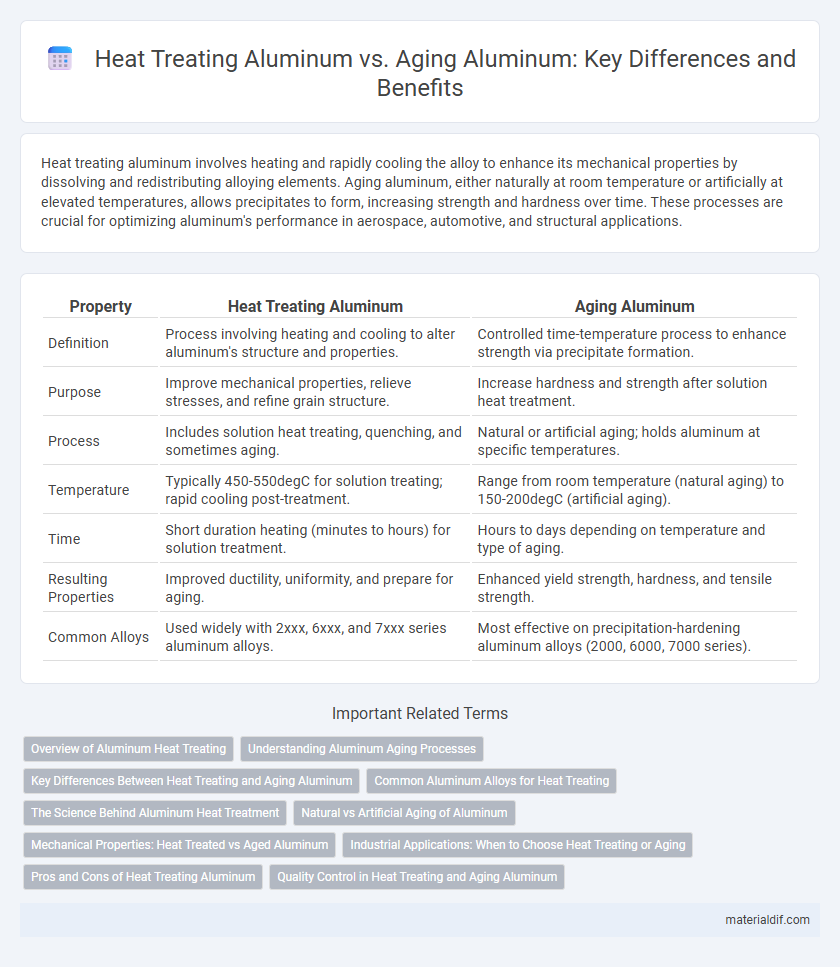

Heat treating aluminum involves heating and rapidly cooling the alloy to enhance its mechanical properties by dissolving and redistributing alloying elements. Aging aluminum, either naturally at room temperature or artificially at elevated temperatures, allows precipitates to form, increasing strength and hardness over time. These processes are crucial for optimizing aluminum's performance in aerospace, automotive, and structural applications.

Table of Comparison

| Property | Heat Treating Aluminum | Aging Aluminum |

|---|---|---|

| Definition | Process involving heating and cooling to alter aluminum's structure and properties. | Controlled time-temperature process to enhance strength via precipitate formation. |

| Purpose | Improve mechanical properties, relieve stresses, and refine grain structure. | Increase hardness and strength after solution heat treatment. |

| Process | Includes solution heat treating, quenching, and sometimes aging. | Natural or artificial aging; holds aluminum at specific temperatures. |

| Temperature | Typically 450-550degC for solution treating; rapid cooling post-treatment. | Range from room temperature (natural aging) to 150-200degC (artificial aging). |

| Time | Short duration heating (minutes to hours) for solution treatment. | Hours to days depending on temperature and type of aging. |

| Resulting Properties | Improved ductility, uniformity, and prepare for aging. | Enhanced yield strength, hardness, and tensile strength. |

| Common Alloys | Used widely with 2xxx, 6xxx, and 7xxx series aluminum alloys. | Most effective on precipitation-hardening aluminum alloys (2000, 6000, 7000 series). |

Overview of Aluminum Heat Treating

Heat treating aluminum involves processes like solution heat treating and quenching to alter the alloy's microstructure, enhancing its mechanical properties and strength. Aging aluminum, either naturally at room temperature or artificially at elevated temperatures, promotes precipitation hardening by forming fine particles that impede dislocation movement. These heat treatment stages optimize aluminum alloys such as 2024, 6061, and 7075 for aerospace, automotive, and structural applications by balancing hardness, ductility, and corrosion resistance.

Understanding Aluminum Aging Processes

Heat treating aluminum involves controlled heating and cooling to alter its microstructure, enhancing strength and hardness through precipitation hardening. Aging aluminum is a specific phase where the alloy is maintained at elevated temperatures to allow precipitates to form and distribute uniformly, significantly improving mechanical properties. Understanding the aging process is crucial for optimizing alloy performance in aerospace, automotive, and structural applications.

Key Differences Between Heat Treating and Aging Aluminum

Heat treating aluminum involves controlled heating and cooling processes to alter the metal's microstructure, improving strength and hardness. Aging aluminum, a subset of heat treatment, specifically refers to the natural or artificial process of allowing the material to attain maximum strength over time through precipitation hardening. Key differences include heat treating's broader scope of processes like annealing and solution heat treatment, while aging focuses on the time-dependent hardening phase to achieve optimal mechanical properties in aluminum alloys.

Common Aluminum Alloys for Heat Treating

Heat treating aluminum involves heating alloys like 6061, 2024, and 7075 to specific temperatures and then rapidly cooling them to alter their mechanical properties and enhance strength. Aging aluminum, a controlled heat treatment process performed after solution heat treating, allows precipitation hardening in alloys such as 6061 and 2024 to improve hardness and tensile strength. Common aluminum alloys used for heat treating and aging include 2xxx, 6xxx, and 7xxx series, each offering a balance of strength, corrosion resistance, and machinability optimized through these thermal processes.

The Science Behind Aluminum Heat Treatment

Heat treating aluminum involves heating the metal to specific temperatures to alter its microstructure, enhancing strength and durability through processes such as solution heat treatment and quenching. Aging aluminum, either naturally at room temperature or artificially at elevated temperatures, precipitates solute atoms within the alloy matrix, which increases hardness and mechanical properties. The controlled diffusion and phase transformations during heat treatment and aging optimize grain structure and precipitate distribution, crucial for achieving desired performance in aerospace, automotive, and construction applications.

Natural vs Artificial Aging of Aluminum

Heat treating aluminum involves controlled heating and cooling processes that improve mechanical properties, while aging aluminum refers to the precipitation hardening stage where strength is enhanced over time. Natural aging occurs at room temperature, gradually increasing hardness without external energy, whereas artificial aging uses elevated temperatures to accelerate precipitate formation and achieve desired mechanical characteristics faster. Understanding the differences between natural and artificial aging in aluminum alloys is crucial for optimizing strength, ductility, and corrosion resistance in aerospace and automotive applications.

Mechanical Properties: Heat Treated vs Aged Aluminum

Heat treating aluminum involves controlled heating and cooling processes to alter its microstructure, significantly enhancing strength, hardness, and tensile properties. Aging aluminum, typically through natural or artificial aging, allows precipitates to form within the alloy matrix, further improving yield strength and fatigue resistance over time. Mechanical properties of heat-treated aluminum often show immediate improvement, while aged aluminum gains strength more gradually, optimizing performance for specific aerospace and automotive applications.

Industrial Applications: When to Choose Heat Treating or Aging

Heat treating aluminum involves controlled heating and cooling to alter mechanical properties such as strength and hardness, making it ideal for high-stress industrial applications like aerospace and automotive manufacturing. Aging aluminum, a natural or artificial process, enhances alloy strength by precipitating solute atoms, commonly used to improve durability in structural components without extensive thermal cycles. Industries prioritize heat treating for rapid property changes and complex shapes, while aging is favored for uniform strength enhancement and cost efficiency in large-scale production.

Pros and Cons of Heat Treating Aluminum

Heat treating aluminum enhances mechanical properties by increasing strength and hardness through controlled heating and cooling processes, making it suitable for critical aerospace and automotive applications. However, heat treating can cause dimensional changes and residual stresses that may require further machining or stress-relief treatments. The process demands precise temperature control to avoid overheating or underheating, which can negatively impact alloy performance and durability.

Quality Control in Heat Treating and Aging Aluminum

Heat treating aluminum involves controlled heating and cooling processes to enhance mechanical properties such as strength and hardness, requiring precise temperature and time monitoring to ensure consistent quality. Aging aluminum, whether natural or artificial, stabilizes the microstructure to achieve desired mechanical characteristics, demanding rigorous quality control measures like hardness testing and tensile strength evaluations. Both processes rely heavily on strict adherence to process parameters and continuous inspection to prevent defects and maintain optimal performance in aluminum alloys.

Heat Treating Aluminum vs Aging Aluminum Infographic

materialdif.com

materialdif.com