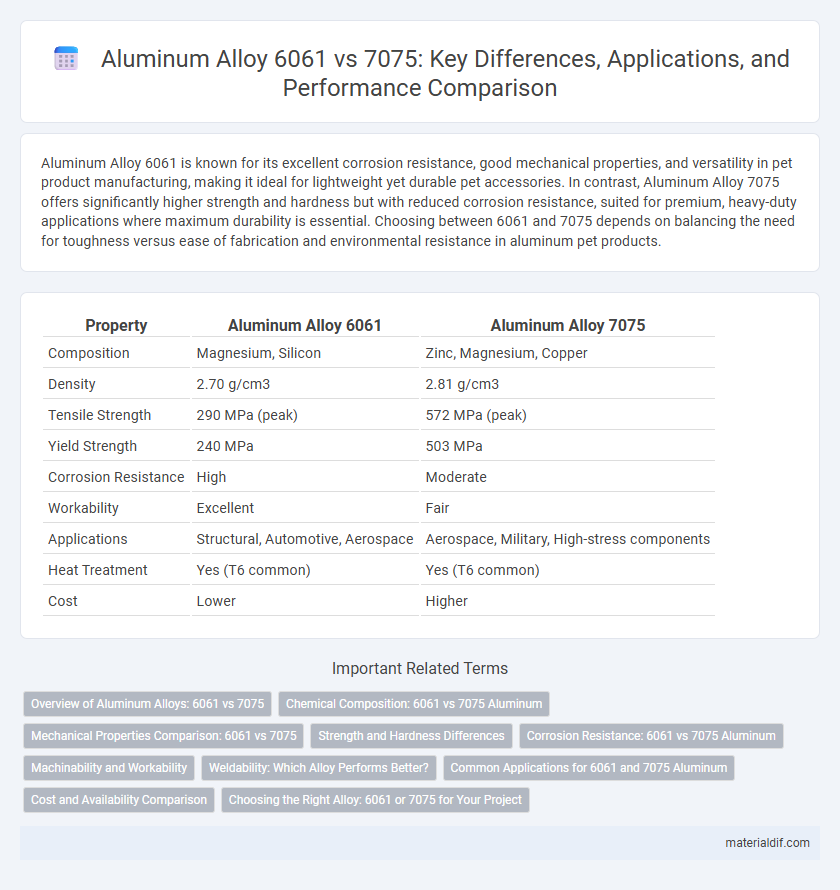

Aluminum Alloy 6061 is known for its excellent corrosion resistance, good mechanical properties, and versatility in pet product manufacturing, making it ideal for lightweight yet durable pet accessories. In contrast, Aluminum Alloy 7075 offers significantly higher strength and hardness but with reduced corrosion resistance, suited for premium, heavy-duty applications where maximum durability is essential. Choosing between 6061 and 7075 depends on balancing the need for toughness versus ease of fabrication and environmental resistance in aluminum pet products.

Table of Comparison

| Property | Aluminum Alloy 6061 | Aluminum Alloy 7075 |

|---|---|---|

| Composition | Magnesium, Silicon | Zinc, Magnesium, Copper |

| Density | 2.70 g/cm3 | 2.81 g/cm3 |

| Tensile Strength | 290 MPa (peak) | 572 MPa (peak) |

| Yield Strength | 240 MPa | 503 MPa |

| Corrosion Resistance | High | Moderate |

| Workability | Excellent | Fair |

| Applications | Structural, Automotive, Aerospace | Aerospace, Military, High-stress components |

| Heat Treatment | Yes (T6 common) | Yes (T6 common) |

| Cost | Lower | Higher |

Overview of Aluminum Alloys: 6061 vs 7075

Aluminum Alloy 6061 features moderate strength, excellent corrosion resistance, and good weldability, making it ideal for structural applications and general-purpose use. In contrast, Aluminum Alloy 7075 offers higher strength and superior fatigue resistance, commonly used in aerospace and high-stress environments but with reduced corrosion resistance and machinability. Both alloys belong to the wrought aluminum family, with 6061 being primarily magnesium and silicon-based, while 7075 is zinc-based, influencing their mechanical properties and typical applications.

Chemical Composition: 6061 vs 7075 Aluminum

Aluminum Alloy 6061 primarily contains magnesium (0.8-1.2%) and silicon (0.4-0.8%) as its major alloying elements, offering good strength and corrosion resistance. In contrast, Aluminum Alloy 7075 features a higher zinc content (5.1-6.1%) along with magnesium (2.1-2.9%) and copper (1.2-2.0%), resulting in superior tensile strength but reduced corrosion resistance. The distinct chemical compositions define their typical applications, with 6061 favored for structural and marine uses and 7075 preferred for aerospace and high-stress environments.

Mechanical Properties Comparison: 6061 vs 7075

Aluminum Alloy 7075 exhibits superior tensile strength up to 83,000 psi compared to 6061's maximum of 45,000 psi, making 7075 ideal for high-stress applications. Alloy 6061 offers better corrosion resistance and weldability, which enhances its versatility in structural components. The yield strength of 7075 surpasses 6061, with 7075 at approximately 73,000 psi versus 6061 at 40,000 psi, reflecting 7075's enhanced performance in aerospace and military uses.

Strength and Hardness Differences

Aluminum Alloy 7075 exhibits significantly higher strength and hardness compared to Aluminum Alloy 6061, making it ideal for high-stress applications such as aerospace and military components. Alloy 6061 offers moderate strength and superior corrosion resistance, suitable for structural and general-purpose use. The tensile strength of 7075 ranges from 572 to 700 MPa, whereas 6061 typically ranges from 240 to 310 MPa, highlighting the stark difference in mechanical properties.

Corrosion Resistance: 6061 vs 7075 Aluminum

Aluminum Alloy 6061 exhibits superior corrosion resistance compared to 7075, making it more suitable for applications exposed to harsh environmental conditions such as marine or chemical environments. 7075 aluminum, while stronger and harder, is more susceptible to stress corrosion cracking and requires protective coatings or anodizing for enhanced durability. The natural oxide layer on 6061 provides better inherent resistance against oxidation and corrosion, contributing to its widespread use in structural and outdoor applications.

Machinability and Workability

Aluminum Alloy 6061 offers superior machinability with its moderate strength and excellent corrosion resistance, making it easier to cut, shape, and weld for various manufacturing processes. In contrast, Aluminum Alloy 7075 provides higher strength but reduced machinability due to its harder composition, which requires more advanced tools and slower machining speeds. Workability is better in 6061 as it responds well to heat treatment and cold working, while 7075 has limited formability and is more prone to cracking during complex forming operations.

Weldability: Which Alloy Performs Better?

Aluminum Alloy 6061 exhibits superior weldability compared to Alloy 7075 due to its moderate strength and excellent corrosion resistance, making it ideal for structural applications requiring reliable joints. Alloy 7075, while stronger and commonly used in aerospace, presents challenges during welding because of its susceptibility to cracking and strength reduction in the heat-affected zone. For projects prioritizing ease of welding and durability, 6061 is the preferred choice over 7075.

Common Applications for 6061 and 7075 Aluminum

Aluminum Alloy 6061 is extensively used in structural applications such as aerospace frames, marine components, and automotive parts due to its excellent corrosion resistance and good mechanical properties. Alloy 7075 is preferred in high-stress environments including aircraft structures, sports equipment, and military-grade hardware for its superior strength and fatigue resistance. Both alloys are essential in industries requiring a balance of lightweight performance and durability.

Cost and Availability Comparison

Aluminum Alloy 6061 is generally more cost-effective and widely available compared to 7075 due to its balanced strength and excellent corrosion resistance, making it a popular choice for structural applications. Alloy 7075, while significantly stronger with superior mechanical properties, comes at a higher price point and is less common in the market, often reserved for aerospace and high-performance engineering uses. Availability of 7075 can be limited, impacting lead times, whereas 6061 benefits from extensive production and distribution networks globally.

Choosing the Right Alloy: 6061 or 7075 for Your Project

Aluminum Alloy 6061 offers excellent corrosion resistance and good weldability, making it ideal for structural applications and general-purpose projects requiring moderate strength. In contrast, Alloy 7075 provides superior strength and fatigue resistance but has lower corrosion resistance, suited for high-stress aerospace and military components. Selecting between 6061 and 7075 depends on balancing strength requirements, environmental exposure, and fabrication processes in your project.

Aluminum Alloy 6061 vs 7075 Infographic

materialdif.com

materialdif.com