Aluminum and magnesium are both lightweight metals commonly used in pet products, but aluminum offers superior corrosion resistance and durability compared to magnesium. While magnesium is lighter, it is more prone to oxidation and structural weakening over time, making aluminum a preferred choice for long-lasting pet accessories. The balance of strength, weight, and resistance makes aluminum ideal for pet carriers, cages, and feeding bowls.

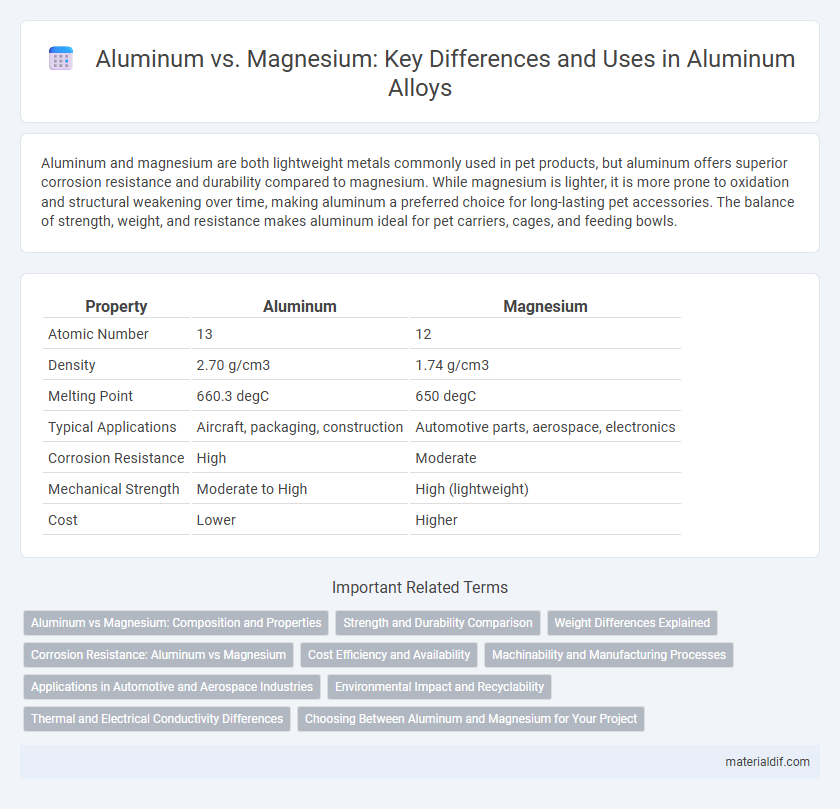

Table of Comparison

| Property | Aluminum | Magnesium |

|---|---|---|

| Atomic Number | 13 | 12 |

| Density | 2.70 g/cm3 | 1.74 g/cm3 |

| Melting Point | 660.3 degC | 650 degC |

| Typical Applications | Aircraft, packaging, construction | Automotive parts, aerospace, electronics |

| Corrosion Resistance | High | Moderate |

| Mechanical Strength | Moderate to High | High (lightweight) |

| Cost | Lower | Higher |

Aluminum vs Magnesium: Composition and Properties

Aluminum primarily consists of metallic aluminum with trace amounts of impurities, offering a lightweight and corrosion-resistant structure with high thermal and electrical conductivity. Magnesium, composed mostly of magnesium alloyed with small amounts of aluminum, zinc, or manganese, is even lighter but has lower strength and corrosion resistance compared to aluminum. The distinct crystal structures--face-centered cubic for aluminum and hexagonal close-packed for magnesium--result in aluminum having better ductility and magnesium providing superior strength-to-weight ratios in specific applications.

Strength and Durability Comparison

Aluminum exhibits high strength-to-weight ratio with excellent corrosion resistance, making it durable in various environmental conditions. Magnesium is lighter than aluminum but generally has lower tensile strength and reduced resistance to wear and corrosion. For applications demanding greater structural integrity and longevity, aluminum often outperforms magnesium due to its superior mechanical properties and enhanced durability.

Weight Differences Explained

Aluminum weighs approximately 2.7 grams per cubic centimeter, making it denser than magnesium, which has a density of about 1.74 grams per cubic centimeter. This difference means magnesium components are significantly lighter than aluminum ones, benefiting applications where weight reduction is critical, such as aerospace and automotive industries. Despite magnesium's lightness, aluminum offers superior strength-to-weight ratios and corrosion resistance, influencing material selection based on specific performance requirements.

Corrosion Resistance: Aluminum vs Magnesium

Aluminum exhibits superior corrosion resistance compared to magnesium due to the formation of a stable, protective oxide layer that prevents further oxidation. Magnesium is more prone to corrosion, especially in salty or marine environments, because it lacks a similarly protective oxide layer and reacts more readily with moisture. Protective coatings and alloying agents can improve magnesium's corrosion resistance but generally do not match the inherent durability of aluminum in corrosive conditions.

Cost Efficiency and Availability

Aluminum offers superior cost efficiency compared to magnesium due to its abundant availability and lower extraction expenses, making it a more economical choice for large-scale manufacturing. Magnesium, although lighter, is less abundant and requires more complex processing, which drives up costs and limits widespread use. This cost and availability advantage makes aluminum the preferred metal in industries seeking affordable, high-volume material solutions.

Machinability and Manufacturing Processes

Aluminum offers superior machinability compared to magnesium due to its lower cutting forces and better surface finish during manufacturing processes. Its higher thermal conductivity and ductility allow for more precise and efficient machining operations, reducing tool wear and cycle time. Magnesium, while lighter, tends to produce more tool vibrations and requires specialized handling to prevent flammability issues during high-speed machining.

Applications in Automotive and Aerospace Industries

Aluminum and magnesium are critical lightweight metals extensively employed in automotive and aerospace industries due to their strength-to-weight ratios. Aluminum's corrosion resistance and higher tensile strength make it ideal for aircraft structures, body panels, and engine components, ensuring durability and safety. Magnesium's lower density offers superior weight reduction benefits for automotive parts like transmission cases and steering wheels, promoting fuel efficiency and performance.

Environmental Impact and Recyclability

Aluminum exhibits a lower environmental impact compared to magnesium due to its higher recyclability rate, with over 75% of aluminum ever produced still in use today, significantly reducing energy consumption and greenhouse gas emissions during recycling. Magnesium production is more energy-intensive and involves environmentally harmful extraction processes, making its lifecycle impact greater despite its lightweight properties. Efficient aluminum recycling infrastructure minimizes waste and conserves natural resources, reinforcing aluminum's advantage in sustainable material management.

Thermal and Electrical Conductivity Differences

Aluminum exhibits higher electrical conductivity, averaging around 37.7 million siemens per meter (MS/m), compared to magnesium's 22.6 MS/m, making aluminum a preferred choice for electrical applications. In terms of thermal conductivity, aluminum also outperforms magnesium, with values near 235 W/m*K, whereas magnesium typically measures around 156 W/m*K, enabling better heat dissipation in aluminum-based components. These differences highlight aluminum's superiority in applications requiring efficient electrical currents and heat transfer.

Choosing Between Aluminum and Magnesium for Your Project

Aluminum offers superior corrosion resistance and higher strength-to-weight ratio compared to magnesium, making it ideal for structural applications requiring durability and longevity. Magnesium is significantly lighter than aluminum, providing advantages in weight-sensitive projects such as aerospace or automotive components where reducing mass is critical. Selecting between aluminum and magnesium depends on balancing factors like mechanical properties, corrosion resistance, weight constraints, and cost considerations specific to the project's needs.

Aluminum vs Magnesium Infographic

materialdif.com

materialdif.com