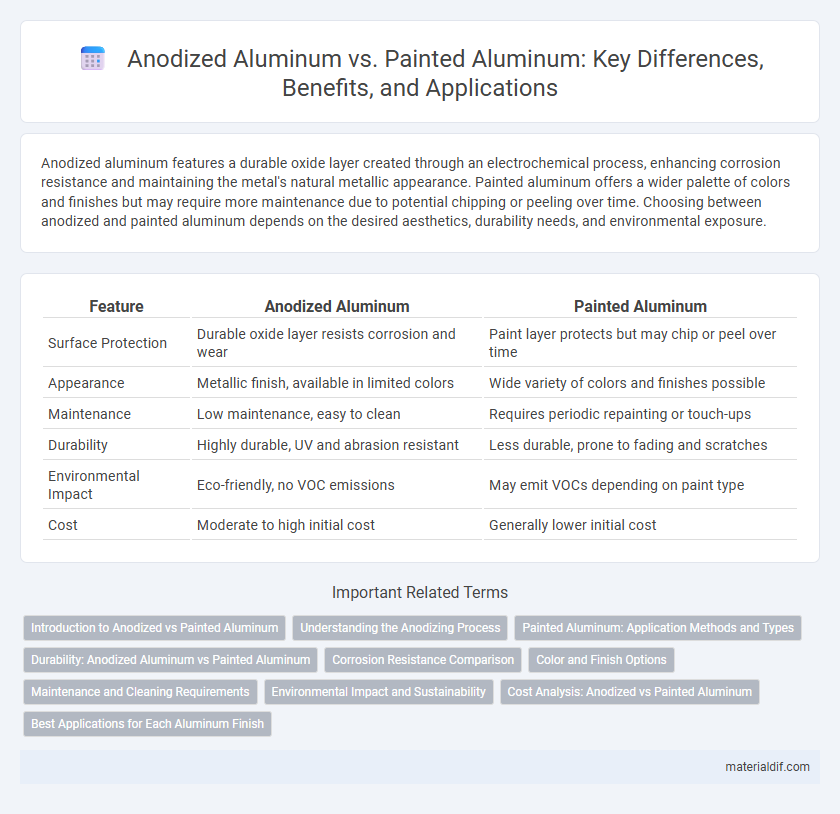

Anodized aluminum features a durable oxide layer created through an electrochemical process, enhancing corrosion resistance and maintaining the metal's natural metallic appearance. Painted aluminum offers a wider palette of colors and finishes but may require more maintenance due to potential chipping or peeling over time. Choosing between anodized and painted aluminum depends on the desired aesthetics, durability needs, and environmental exposure.

Table of Comparison

| Feature | Anodized Aluminum | Painted Aluminum |

|---|---|---|

| Surface Protection | Durable oxide layer resists corrosion and wear | Paint layer protects but may chip or peel over time |

| Appearance | Metallic finish, available in limited colors | Wide variety of colors and finishes possible |

| Maintenance | Low maintenance, easy to clean | Requires periodic repainting or touch-ups |

| Durability | Highly durable, UV and abrasion resistant | Less durable, prone to fading and scratches |

| Environmental Impact | Eco-friendly, no VOC emissions | May emit VOCs depending on paint type |

| Cost | Moderate to high initial cost | Generally lower initial cost |

Introduction to Anodized vs Painted Aluminum

Anodized aluminum features a durable, corrosion-resistant oxide layer formed through electrochemical processes, enhancing surface hardness and wear resistance. Painted aluminum provides a protective and aesthetic coating that shields against environmental damage but is more prone to chipping and scratching compared to anodized finishes. Both treatments improve aluminum's longevity, yet anodizing integrates into the metal's surface while painting forms an external barrier.

Understanding the Anodizing Process

The anodizing process enhances aluminum by creating a durable, corrosion-resistant oxide layer through an electrochemical reaction, unlike painted aluminum which relies on surface coatings that can chip or peel. This oxide layer integrates with the aluminum substrate, providing superior wear resistance and color stability without adding thickness. Anodized aluminum is ideal for environments demanding long-term durability and minimal maintenance compared to painted finishes.

Painted Aluminum: Application Methods and Types

Painted aluminum is commonly applied using methods such as spray painting, powder coating, and electrostatic coating, each offering distinct advantages in finish quality and durability. Spray painting provides a smooth, even layer suitable for intricate shapes, while powder coating delivers a thicker, more resistant surface ideal for outdoor applications. Electrostatic coating enhances adhesion and reduces waste, making it a preferred choice for industrial and automotive aluminum components.

Durability: Anodized Aluminum vs Painted Aluminum

Anodized aluminum provides superior durability compared to painted aluminum due to its hard, corrosion-resistant oxide layer formed through an electrochemical process, which enhances resistance to abrasion, UV rays, and weather exposure. Painted aluminum, while offering aesthetic versatility, tends to chip, peel, or fade over time when exposed to harsh environmental conditions, requiring more frequent maintenance. The long-lasting protective barrier of anodized aluminum makes it a preferred choice for applications demanding extended performance and minimal upkeep.

Corrosion Resistance Comparison

Anodized aluminum features a thick oxide layer that significantly enhances corrosion resistance by preventing moisture and contaminants from reaching the metal surface. Painted aluminum relies on the protective coating to shield the metal but is susceptible to chipping and degradation, which can expose the aluminum to corrosion over time. Anodizing offers superior durability and longer-lasting corrosion protection compared to painted finishes, especially in harsh environments.

Color and Finish Options

Anodized aluminum offers a durable, corrosion-resistant finish with colors that are typically metallic and subtle, including shades of silver, gold, black, and bronze due to the electrochemical process creating a permanent oxide layer. Painted aluminum provides a broader spectrum of vibrant, customizable colors and finishes, including matte, gloss, and satin, allowing for greater design flexibility but with less durability compared to anodizing. Both finishes impact the aesthetic and protective qualities, with anodized aluminum favored for long-lasting, natural metallic appearances and painted aluminum chosen for vivid, diverse color options.

Maintenance and Cleaning Requirements

Anodized aluminum offers superior resistance to corrosion and scratches, making maintenance minimal compared to painted aluminum, which can chip or peel over time and require more frequent touch-ups. Cleaning anodized aluminum involves mild soap and water without harsh chemicals, preserving its durable oxide layer, whereas painted aluminum may need specialized cleaners to prevent damage to the paint finish. The long-term durability of anodized aluminum reduces overall maintenance costs and efforts relative to painted surfaces in various environmental conditions.

Environmental Impact and Sustainability

Anodized aluminum offers superior environmental benefits compared to painted aluminum due to its non-toxic anodic oxide layer, which is created through an electrochemical process that enhances corrosion resistance without harmful chemical coatings. Painted aluminum involves organic solvents and volatile organic compounds (VOCs), contributing to air pollution and hazards during application and disposal. The durability and recyclability of anodized aluminum improve sustainability by reducing maintenance needs and enabling efficient material recovery.

Cost Analysis: Anodized vs Painted Aluminum

Anodized aluminum generally incurs higher initial costs due to its electrochemical surface treatment that enhances corrosion resistance and durability. Painted aluminum offers a lower upfront price but may require more frequent maintenance and repainting, leading to increased long-term expenses. Evaluating total cost of ownership favors anodized aluminum for applications demanding longevity and minimal upkeep.

Best Applications for Each Aluminum Finish

Anodized aluminum offers superior corrosion resistance and durability, making it ideal for outdoor applications such as architectural panels, marine equipment, and automotive parts where long-lasting protection is crucial. Painted aluminum provides a broader range of color options and aesthetic versatility, suited for decorative elements, indoor furniture, and signage that require customizable finishes. Choosing between anodized and painted aluminum depends on the balance of desired appearance, environmental exposure, and maintenance requirements.

Anodized Aluminum vs Painted Aluminum Infographic

materialdif.com

materialdif.com