Forged aluminum offers superior strength and durability compared to billet aluminum due to its compressed grain structure formed under high pressure. Billet aluminum, sourced from solid blocks, provides greater customization and precision machining capabilities but may lack the uniform strength of forged counterparts. Choosing between forged and billet aluminum depends on the specific requirements for performance, weight, and design complexity in aluminum PET applications.

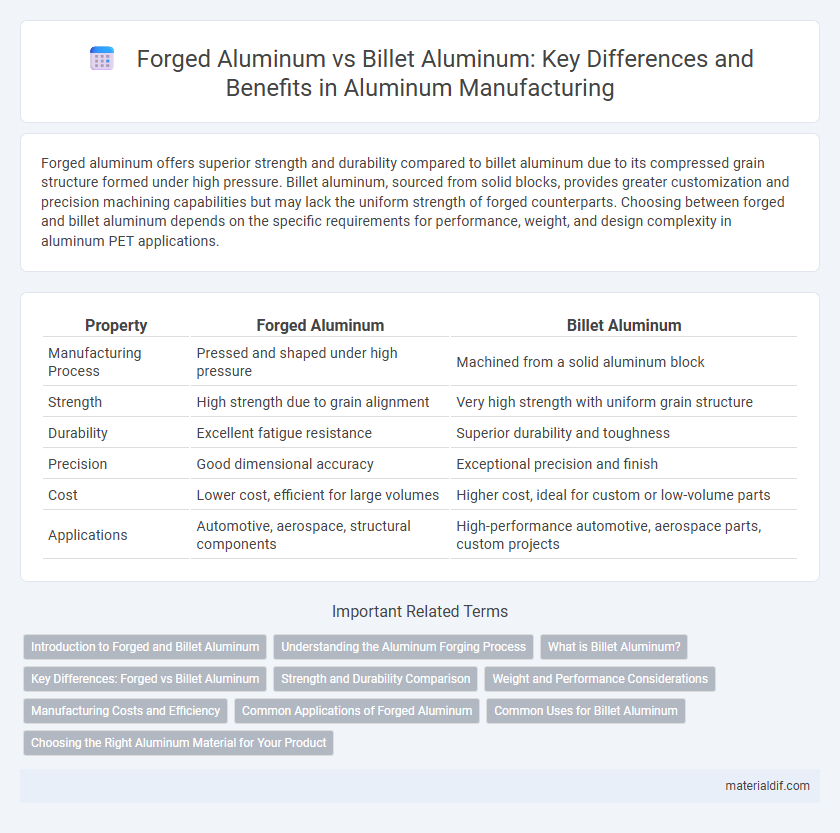

Table of Comparison

| Property | Forged Aluminum | Billet Aluminum |

|---|---|---|

| Manufacturing Process | Pressed and shaped under high pressure | Machined from a solid aluminum block |

| Strength | High strength due to grain alignment | Very high strength with uniform grain structure |

| Durability | Excellent fatigue resistance | Superior durability and toughness |

| Precision | Good dimensional accuracy | Exceptional precision and finish |

| Cost | Lower cost, efficient for large volumes | Higher cost, ideal for custom or low-volume parts |

| Applications | Automotive, aerospace, structural components | High-performance automotive, aerospace parts, custom projects |

Introduction to Forged and Billet Aluminum

Forged aluminum is produced by shaping heated aluminum using compressive forces, resulting in enhanced strength and structural integrity through a refined grain flow. Billet aluminum is crafted from a solid block of aluminum that is CNC-machined into precise shapes, offering high dimensional accuracy and a clean finish. Both methods provide unique mechanical properties tailored for applications requiring lightweight yet durable materials, widely used in automotive and aerospace industries.

Understanding the Aluminum Forging Process

The aluminum forging process involves shaping heated aluminum between dies to enhance grain structure and mechanical properties, resulting in stronger and more durable components compared to billet aluminum, which is machined from a solid block. Forged aluminum offers improved strength-to-weight ratios and superior fatigue resistance, making it ideal for high-stress applications such as aerospace and automotive industries. Understanding this process highlights the benefits of forged aluminum in delivering optimized performance through controlled deformation and refined microstructure.

What is Billet Aluminum?

Billet aluminum is a solid block of high-quality aluminum alloy, typically produced through a continuous casting process that ensures uniform grain structure and superior mechanical properties. It is prized for its strength, durability, and machinability, making it ideal for precision engineering applications such as aerospace, automotive, and custom parts manufacturing. Compared to forged aluminum, billet aluminum offers greater versatility in complex shapes and tighter tolerances due to its uniform composition and ability to be CNC machined with minimal material waste.

Key Differences: Forged vs Billet Aluminum

Forged aluminum undergoes high-pressure shaping, resulting in superior strength, enhanced grain structure, and improved fatigue resistance compared to billet aluminum, which is machined from a solid block for greater design flexibility and precision. While forged aluminum offers higher durability and impact resistance ideal for high-stress applications, billet aluminum provides customized geometries and intricate detailing suitable for specialized components. Understanding these key differences is essential for selecting the appropriate aluminum type based on strength requirements, manufacturing complexity, and performance criteria.

Strength and Durability Comparison

Forged aluminum typically offers superior strength and durability compared to billet aluminum due to its grain flow alignment, which enhances resistance to impact and fatigue. Billet aluminum, while strong and precise in shape, may contain stress concentrations from machining that can reduce its overall durability under heavy loads. For high-performance applications requiring maximum toughness and longevity, forged aluminum is generally the preferred material choice.

Weight and Performance Considerations

Forged aluminum offers superior strength-to-weight ratio due to its grain structure alignment, resulting in lighter components with enhanced durability compared to billet aluminum. Billet aluminum, machined from solid blocks, typically has a uniform density but can be heavier and less impact-resistant under dynamic loads. Performance-driven applications prioritize forged aluminum for its optimal balance of lightweight design and high mechanical strength.

Manufacturing Costs and Efficiency

Forged aluminum typically offers lower manufacturing costs and higher production efficiency compared to billet aluminum due to faster process cycles and less machining waste. Billet aluminum requires extensive CNC machining from solid blocks, increasing both material waste and labor expenses. Industries prioritize forged aluminum for cost-effective mass production, while billet aluminum suits specialized applications demanding complex geometries despite higher expenses.

Common Applications of Forged Aluminum

Forged aluminum is widely used in automotive and aerospace industries due to its superior strength and fatigue resistance, making it ideal for engine components, suspension parts, and aircraft structural elements. Its ability to withstand high stress and impact loads ensures reliability in performance-critical applications. Additionally, forged aluminum finds common usage in sporting goods and industrial machinery where durability and lightweight properties are essential.

Common Uses for Billet Aluminum

Billet aluminum is commonly used in high-performance automotive parts, aerospace components, and custom motorcycle frames due to its superior strength and precision machining capabilities. Its uniform grain structure allows for enhanced durability in critical applications such as engine blocks, suspension parts, and structural components. Manufacturers prefer billet aluminum for custom tooling and prototypes where exact dimensions and complex shapes are required.

Choosing the Right Aluminum Material for Your Product

Forged aluminum offers superior strength and durability due to its grain structure alignment, making it ideal for high-stress applications. Billet aluminum provides excellent precision and surface finish, enabling complex designs and tight tolerances for specialized components. Selecting between forged and billet aluminum depends on your product's performance requirements, cost constraints, and manufacturing complexity.

Forged aluminum vs billet aluminum Infographic

materialdif.com

materialdif.com