Sandblasting creates a textured matte finish on aluminum PET surfaces by propelling abrasive materials at high speed, enhancing adhesion and masking imperfections. Polishing, on the other hand, produces a smooth, reflective shine by removing surface irregularities through mechanical abrasion, resulting in a sleek and glossy appearance. Choosing between sandblasting and polishing depends on the desired aesthetic and functional requirements of the aluminum PET application.

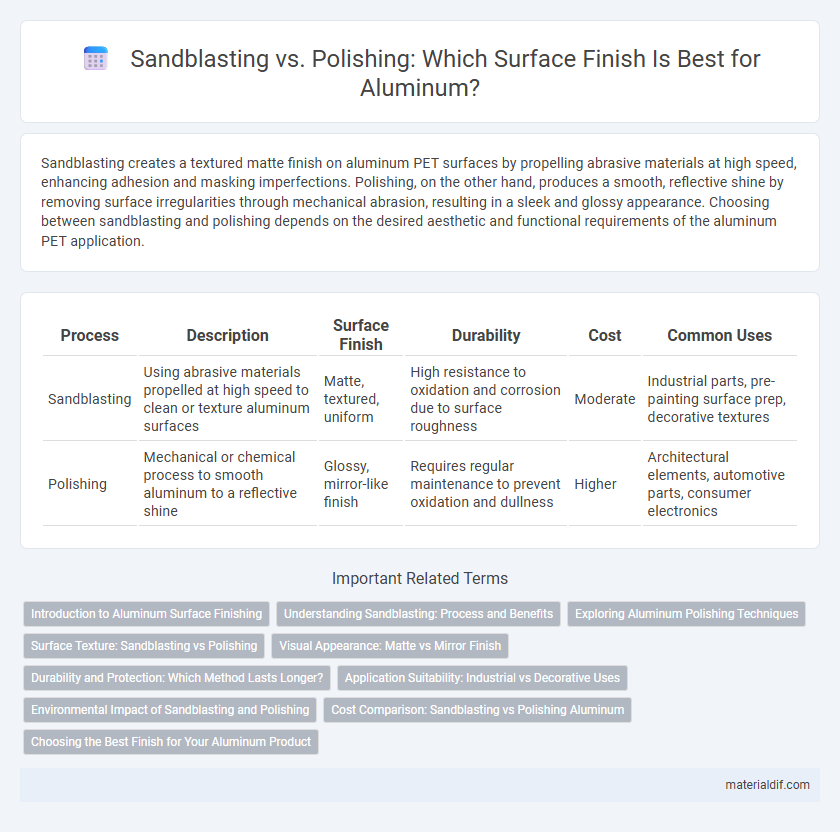

Table of Comparison

| Process | Description | Surface Finish | Durability | Cost | Common Uses |

|---|---|---|---|---|---|

| Sandblasting | Using abrasive materials propelled at high speed to clean or texture aluminum surfaces | Matte, textured, uniform | High resistance to oxidation and corrosion due to surface roughness | Moderate | Industrial parts, pre-painting surface prep, decorative textures |

| Polishing | Mechanical or chemical process to smooth aluminum to a reflective shine | Glossy, mirror-like finish | Requires regular maintenance to prevent oxidation and dullness | Higher | Architectural elements, automotive parts, consumer electronics |

Introduction to Aluminum Surface Finishing

Aluminum surface finishing techniques like sandblasting and polishing significantly impact the metal's appearance, durability, and corrosion resistance. Sandblasting uses abrasive particles to create a textured matte finish ideal for removing imperfections and preparing surfaces for further coating. Polishing produces a smooth, reflective surface by mechanically buffing aluminum, enhancing its aesthetic appeal and facilitating easier cleaning.

Understanding Sandblasting: Process and Benefits

Sandblasting aluminum involves propelling abrasive materials at high velocity to clean, etch, or texture the surface, enhancing adhesion for paints or coatings. This process removes oxides and contaminants, resulting in a uniform matte finish that improves corrosion resistance and surface durability. Compared to polishing, sandblasting offers greater efficiency in preparing aluminum for further treatments while reducing surface imperfections.

Exploring Aluminum Polishing Techniques

Aluminum polishing techniques enhance the metal's surface by removing oxidation and fine scratches, resulting in a reflective, smooth finish ideal for automotive, aerospace, and decorative applications. Unlike sandblasting, which uses abrasive materials to create a textured, matte surface, polishing involves progressively finer abrasives and compounds to achieve a mirror-like sheen that improves corrosion resistance and aesthetic appeal. Common polishing methods for aluminum include mechanical polishing with buffing wheels and chemical polishing using alkaline solutions, each optimized for different levels of finish and durability.

Surface Texture: Sandblasting vs Polishing

Sandblasting creates a rough, matte surface texture on aluminum by forcibly propelling abrasive materials, enhancing adhesion for coatings and paint. Polishing produces a smooth, reflective, and shiny finish by mechanically buffing the aluminum surface, reducing surface irregularities to a glossy sheen. The choice between sandblasting and polishing impacts durability, corrosion resistance, and aesthetic appeal based on the aluminum's intended application.

Visual Appearance: Matte vs Mirror Finish

Sandblasting aluminum produces a matte finish that diffuses light and reduces glare, creating a uniform, textured surface ideal for industrial applications. Polishing aluminum results in a mirror finish with high reflectivity, enhancing brightness and highlighting the metal's natural luster for decorative or aesthetic purposes. The choice between sandblasting and polishing directly impacts the visual appearance, with sandblasting offering a muted, non-reflective look and polishing providing a smooth, glossy surface.

Durability and Protection: Which Method Lasts Longer?

Sandblasting creates a durable, textured surface on aluminum that enhances corrosion resistance by removing contaminants and promoting adhesion of protective coatings. Polishing produces a smooth, reflective finish that resists oxidation but is more susceptible to scratches and wear over time. The longevity of protection depends on environmental exposure, with sandblasted aluminum generally offering superior durability in harsh conditions compared to polished aluminum.

Application Suitability: Industrial vs Decorative Uses

Sandblasting aluminum is ideal for industrial applications due to its ability to create a uniform, matte surface that improves paint adhesion and corrosion resistance. Polishing aluminum, in contrast, is suited for decorative uses where a reflective, smooth finish enhances aesthetic appeal and surface brilliance. Selecting between sandblasting and polishing depends on whether durability and surface preparation or visual enhancement is the primary requirement.

Environmental Impact of Sandblasting and Polishing

Sandblasting aluminum involves the use of abrasive materials that can generate dust and waste, potentially harming the environment if not properly contained and disposed of. Polishing aluminum typically requires fewer abrasive materials and often uses chemical cleaners that, if managed correctly, result in less environmental contamination compared to sandblasting. Proper waste management and environmentally friendly materials are crucial in reducing the ecological footprint of both sandblasting and polishing aluminum surfaces.

Cost Comparison: Sandblasting vs Polishing Aluminum

Sandblasting aluminum generally incurs lower upfront costs due to minimal equipment and faster process time compared to polishing, which demands specialized machinery and skilled labor. Polishing aluminum often results in higher maintenance and operational expenses because of ongoing consumables like polishing compounds and pads. Cost efficiency depends on project scale and desired finish quality, with sandblasting favored for rough textures and polishing preferred for smooth, reflective surfaces.

Choosing the Best Finish for Your Aluminum Product

Selecting the best finish for your aluminum product depends on the desired surface texture and application requirements. Sandblasting provides a matte, uniform finish that enhances paint adhesion and hides imperfections, making it ideal for industrial or decorative uses where durability is key. Polishing creates a smooth, reflective surface that enhances aesthetic appeal and corrosion resistance, preferred for consumer products or architectural elements demanding a high-gloss appearance.

Sandblasting vs Polishing Infographic

materialdif.com

materialdif.com