Hard anodizing creates a thicker, denser oxide layer on aluminum, enhancing wear resistance and corrosion protection for industrial applications. Soft anodizing produces a thinner, more decorative coating that improves surface appearance and provides basic corrosion resistance. Choosing between hard and soft anodizing depends on the required durability and aesthetic needs of the aluminum product.

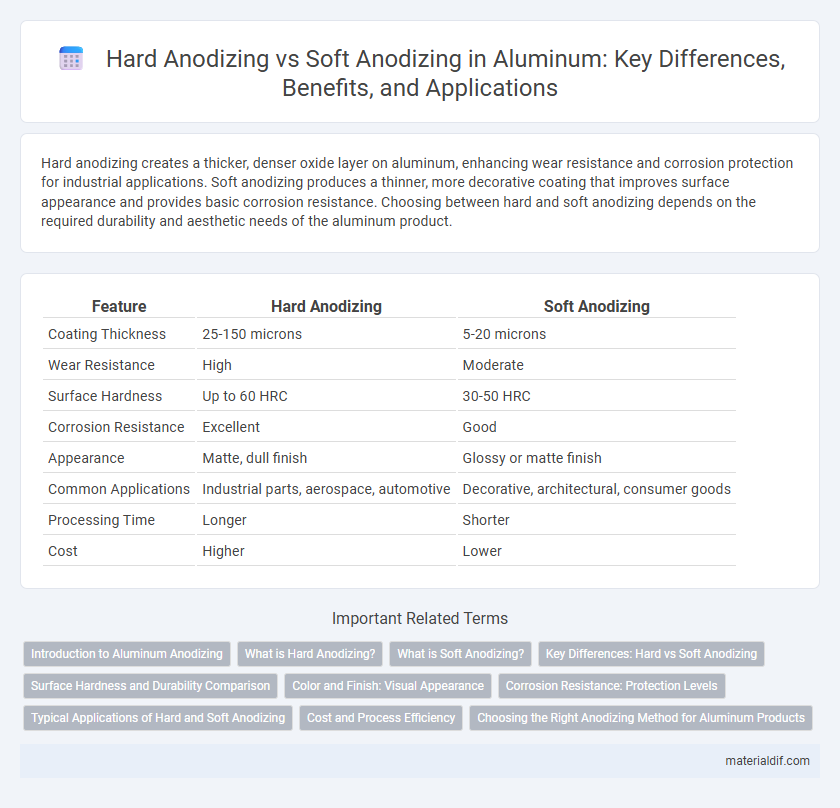

Table of Comparison

| Feature | Hard Anodizing | Soft Anodizing |

|---|---|---|

| Coating Thickness | 25-150 microns | 5-20 microns |

| Wear Resistance | High | Moderate |

| Surface Hardness | Up to 60 HRC | 30-50 HRC |

| Corrosion Resistance | Excellent | Good |

| Appearance | Matte, dull finish | Glossy or matte finish |

| Common Applications | Industrial parts, aerospace, automotive | Decorative, architectural, consumer goods |

| Processing Time | Longer | Shorter |

| Cost | Higher | Lower |

Introduction to Aluminum Anodizing

Aluminum anodizing enhances corrosion resistance and surface durability by forming a protective oxide layer through an electrochemical process. Hard anodizing produces a thicker, denser oxide layer, ideal for wear resistance and heavy-duty applications, while soft anodizing results in a thinner, more decorative finish suited for aesthetic purposes. Both methods improve aluminum's lifespan and performance but differ significantly in oxide layer properties and application suitability.

What is Hard Anodizing?

Hard anodizing is an electrochemical process applied to aluminum that produces a thicker, denser oxide layer typically between 25 to 150 microns, significantly enhancing surface hardness and wear resistance up to 60-70 HRC. This specialized anodic coating provides superior corrosion protection and increased resistance to abrasion compared to soft anodizing, making it ideal for high-performance applications in aerospace, automotive, and industrial machinery. The process involves lower temperatures and higher current densities, resulting in a matte or satin finish with improved durability under extreme conditions.

What is Soft Anodizing?

Soft anodizing is a surface treatment process for aluminum that produces a thin, porous oxide layer typically ranging from 5 to 25 microns in thickness. This type of anodizing enhances corrosion resistance and improves surface adhesion without significantly affecting the metal's dimensions or mechanical properties. Soft anodized aluminum is commonly used in applications requiring moderate wear resistance and decorative finishes.

Key Differences: Hard vs Soft Anodizing

Hard anodizing creates a thicker, denser oxide layer on aluminum surfaces, enhancing wear resistance and corrosion protection compared to soft anodizing. Soft anodizing produces a thinner, more porous coating, primarily improving aesthetic appearance and basic surface protection. The key differences lie in coating thickness, hardness, and application suitability, with hard anodizing preferred for industrial uses requiring durability and soft anodizing for decorative or light-duty purposes.

Surface Hardness and Durability Comparison

Hard anodizing of aluminum produces a significantly thicker oxide layer ranging from 50 to 150 microns, resulting in surface hardness up to 60-70 HRC (Rockwell Hardness Scale), which greatly enhances wear and abrasion resistance compared to soft anodizing's thinner layer of about 5-25 microns and hardness around 15-20 HRC. The denser and more compact oxide structure in hard anodized aluminum offers superior durability against corrosion and mechanical damage in extreme environments, making it ideal for industrial applications. Soft anodizing, with its lighter coating, is better suited for decorative purposes or applications requiring electrical insulation but provides less protection under heavy wear conditions.

Color and Finish: Visual Appearance

Hard anodizing produces a thicker, more durable oxide layer on aluminum, resulting in a matte, uniform finish with limited color options, typically in shades of gray to black. Soft anodizing creates a thinner oxide layer that allows for a wider range of vibrant colors and smoother, glossier surfaces. The difference in oxide thickness directly impacts the visual appearance, with hard anodizing offering enhanced wear resistance and a subdued aesthetic compared to the more decorative and colorful finish of soft anodizing.

Corrosion Resistance: Protection Levels

Hard anodizing creates a thicker, denser oxide layer on aluminum surfaces, significantly enhancing corrosion resistance and making it ideal for harsh environments. Soft anodizing produces a thinner oxide coating that provides moderate corrosion protection suitable for less demanding applications. The higher protection levels of hard anodizing result from increased surface hardness and reduced porosity, which effectively shield the aluminum from chemical exposure and wear.

Typical Applications of Hard and Soft Anodizing

Hard anodizing is typically applied in industries requiring enhanced surface hardness and wear resistance, such as aerospace components, automotive parts, and industrial machinery. Soft anodizing is commonly used for decorative finishes, corrosion protection, and improving paint adhesion in consumer electronics, architectural elements, and household appliances. Both processes enhance aluminum's durability but target different application needs based on the required surface characteristics.

Cost and Process Efficiency

Hard anodizing on aluminum offers higher durability and thickness but involves longer processing times and increased energy consumption, leading to higher costs. Soft anodizing uses shorter cycles and lower voltage, resulting in cost-effective production with less energy usage but produces a thinner, less wear-resistant coating. Manufacturers prioritize soft anodizing for low-cost, high-efficiency applications, while hard anodizing suits industries demanding superior surface protection despite higher expenses.

Choosing the Right Anodizing Method for Aluminum Products

Hard anodizing creates a thicker, harder oxide layer on aluminum, enhancing wear resistance and corrosion protection for industrial and high-stress applications. Soft anodizing produces a thinner, decorative oxide layer that improves surface finish and color options, ideal for consumer products requiring aesthetic appeal. Selecting the right anodizing method depends on the aluminum product's functional requirements, balancing durability and appearance for optimal performance.

Hard Anodizing vs Soft Anodizing Infographic

materialdif.com

materialdif.com