Aluminum welding creates a strong, continuous joint by melting the base metal and filler material, providing structural integrity ideal for high-stress applications. Aluminum brazing joins metals using a lower melting point filler alloy without melting the base aluminum, preserving its properties and reducing distortion. Choosing between aluminum welding and brazing depends on the required joint strength, application conditions, and the need to minimize thermal impact on the aluminum components.

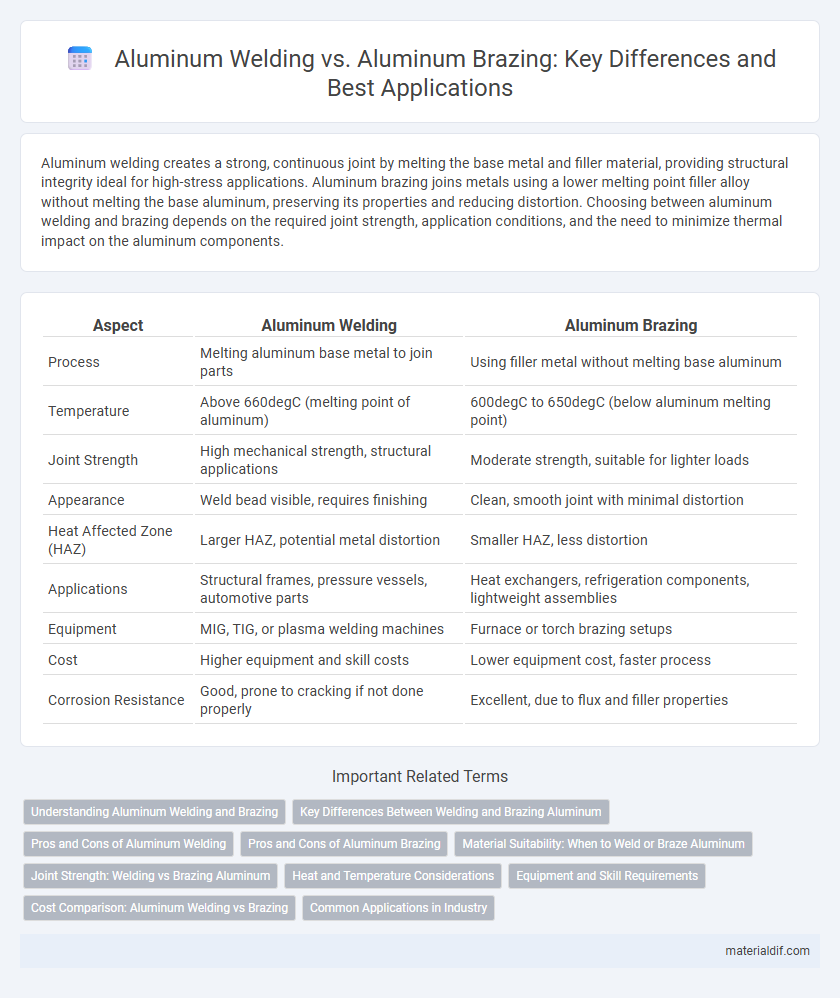

Table of Comparison

| Aspect | Aluminum Welding | Aluminum Brazing |

|---|---|---|

| Process | Melting aluminum base metal to join parts | Using filler metal without melting base aluminum |

| Temperature | Above 660degC (melting point of aluminum) | 600degC to 650degC (below aluminum melting point) |

| Joint Strength | High mechanical strength, structural applications | Moderate strength, suitable for lighter loads |

| Appearance | Weld bead visible, requires finishing | Clean, smooth joint with minimal distortion |

| Heat Affected Zone (HAZ) | Larger HAZ, potential metal distortion | Smaller HAZ, less distortion |

| Applications | Structural frames, pressure vessels, automotive parts | Heat exchangers, refrigeration components, lightweight assemblies |

| Equipment | MIG, TIG, or plasma welding machines | Furnace or torch brazing setups |

| Cost | Higher equipment and skill costs | Lower equipment cost, faster process |

| Corrosion Resistance | Good, prone to cracking if not done properly | Excellent, due to flux and filler properties |

Understanding Aluminum Welding and Brazing

Aluminum welding involves melting the base metal to create a strong, fused joint typically using TIG or MIG welding techniques, which are ideal for structural applications requiring high strength and durability. Aluminum brazing, on the other hand, joins metals by melting a filler alloy with a lower melting point than aluminum, avoiding melting the base metal and producing less thermal distortion, making it suitable for thin or heat-sensitive parts. Understanding the differences in heat application, joint strength, and suitable materials is essential for optimizing the performance and longevity of aluminum assemblies.

Key Differences Between Welding and Brazing Aluminum

Aluminum welding involves melting the base metal to create a strong, fused joint, while aluminum brazing uses a filler metal with a lower melting point to join parts without melting the aluminum itself. Welding typically offers superior mechanical strength and is suitable for structural applications, whereas brazing provides better aesthetics and is often used for joining complex assemblies with thin materials. The heat input in welding is higher, increasing the risk of distortion, while brazing operates at lower temperatures, minimizing thermal stress on aluminum components.

Pros and Cons of Aluminum Welding

Aluminum welding provides strong, permanent joints with excellent mechanical strength and good electrical conductivity, making it ideal for structural applications and high-stress environments. However, it requires precise control of heat input due to aluminum's high thermal conductivity and oxide layer, leading to potential warping, porosity, and cracking if not performed correctly. Despite these challenges, welding offers superior joint integrity compared to brazing, which relies on filler metals and lower temperatures, resulting in weaker bonds and limited suitability for load-bearing components.

Pros and Cons of Aluminum Brazing

Aluminum brazing offers advantages such as lower temperatures that reduce warping and distortion, making it ideal for joining thin or delicate aluminum components. It provides strong, leak-resistant joints with excellent corrosion resistance, especially suitable for heat exchangers and automotive radiators. However, aluminum brazing typically requires flux and careful surface preparation, and the brazed joints may exhibit lower mechanical strength compared to welded aluminum parts.

Material Suitability: When to Weld or Braze Aluminum

Aluminum welding is best suited for thick, load-bearing components where a strong, continuous joint is essential, especially in structural applications like automotive frames and aerospace parts. Aluminum brazing is ideal for joining thin or delicate aluminum sheets and complex assemblies requiring minimal thermal distortion, such as heat exchangers and electronic housings. Material thickness, joint design, and required mechanical strength guide the choice between welding and brazing aluminum.

Joint Strength: Welding vs Brazing Aluminum

Aluminum welding creates stronger joints by fusing base metals through melting, resulting in high structural integrity suitable for load-bearing applications. Aluminum brazing joins metals with a filler alloy melted at lower temperatures, producing joints with less strength and limited mechanical load capacity. Welding generally offers superior joint strength compared to brazing, which is preferred for corrosion resistance and joining dissimilar metals.

Heat and Temperature Considerations

Aluminum welding requires higher temperatures, typically above 600degC, to melt the base metal and create a strong, fusion bond, whereas aluminum brazing operates at lower temperatures, around 450degC to 600degC, using a filler metal to join parts without melting the base metal. The heat input in welding can cause distortion and requires careful control to prevent warping and cracking due to aluminum's high thermal conductivity. Brazing's lower temperatures minimize thermal stress and oxidation, making it suitable for complex or thin aluminum components where heat damage is a concern.

Equipment and Skill Requirements

Aluminum welding requires specialized equipment such as TIG or MIG welders with precise control over heat input and shielding gas to prevent oxidation. Skilled welders must possess advanced knowledge of aluminum's thermal properties and the ability to manage its high thermal conductivity and oxide layer. In contrast, aluminum brazing demands less complex equipment, typically involving a torch and filler metals with lower melting points, but still requires proficiency in temperature control and joint preparation for strong, corrosion-resistant bonds.

Cost Comparison: Aluminum Welding vs Brazing

Aluminum welding typically incurs higher costs due to specialized equipment, skilled labor requirements, and longer processing times compared to aluminum brazing. Brazing offers a cost-efficient alternative by using lower temperatures and simpler setups, reducing energy consumption and minimizing material distortion. When evaluating overall expenses, brazing often provides significant savings in labor and operational costs, especially for thin or delicate aluminum components.

Common Applications in Industry

Aluminum welding is widely used in the aerospace and automotive industries for fabricating structural components requiring high strength and durability, such as aircraft frames and vehicle chassis. Aluminum brazing is commonly applied in HVAC systems and heat exchangers, where joining thin aluminum sheets with corrosion resistance and thermal conductivity is essential. Both techniques are essential in manufacturing but serve different functions based on material thickness and mechanical requirements.

Aluminum Welding vs Aluminum Brazing Infographic

materialdif.com

materialdif.com