6063 aluminum is prized for its excellent corrosion resistance and smooth surface finish, making it ideal for architectural applications and lightweight structural components. In contrast, 2024 aluminum offers superior strength and fatigue resistance, commonly used in aerospace and military industries where durability under stress is critical. Choosing between 6063 and 2024 aluminum depends on the balance required between strength, corrosion resistance, and fabrication needs.

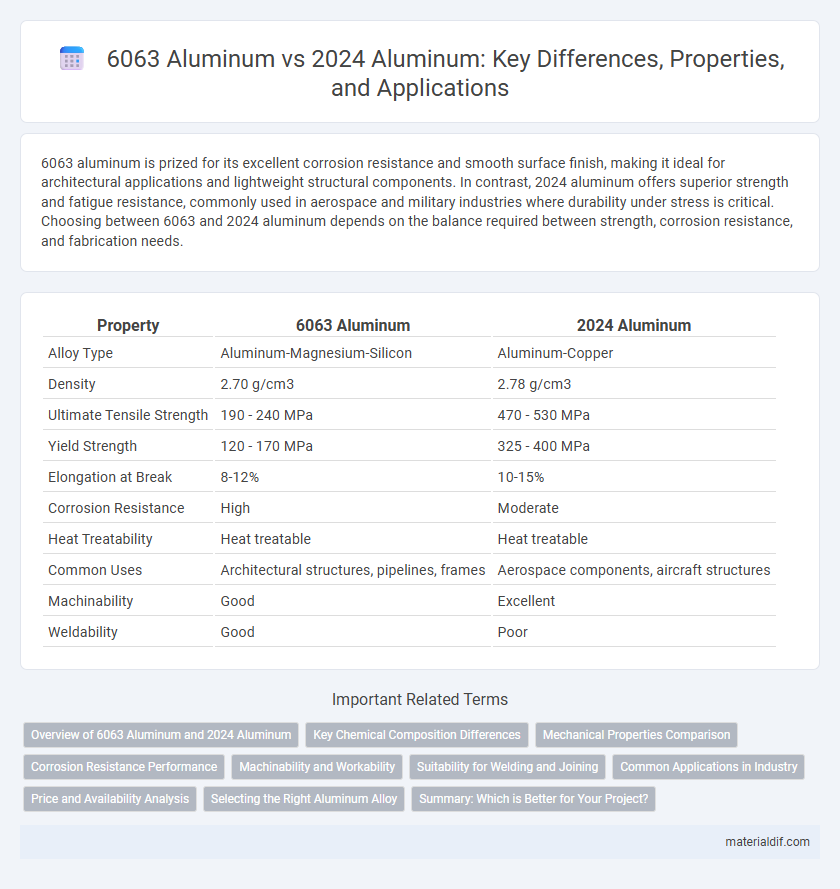

Table of Comparison

| Property | 6063 Aluminum | 2024 Aluminum |

|---|---|---|

| Alloy Type | Aluminum-Magnesium-Silicon | Aluminum-Copper |

| Density | 2.70 g/cm3 | 2.78 g/cm3 |

| Ultimate Tensile Strength | 190 - 240 MPa | 470 - 530 MPa |

| Yield Strength | 120 - 170 MPa | 325 - 400 MPa |

| Elongation at Break | 8-12% | 10-15% |

| Corrosion Resistance | High | Moderate |

| Heat Treatability | Heat treatable | Heat treatable |

| Common Uses | Architectural structures, pipelines, frames | Aerospace components, aircraft structures |

| Machinability | Good | Excellent |

| Weldability | Good | Poor |

Overview of 6063 Aluminum and 2024 Aluminum

6063 aluminum is a medium-strength alloy primarily composed of magnesium and silicon, known for its excellent corrosion resistance, good surface finish, and high extrudability, making it ideal for architectural applications and structural tubing. In contrast, 2024 aluminum is a high-strength alloy containing copper as the principal alloying element, offering superior fatigue resistance and machinability, widely used in aerospace and military sectors. While 6063 emphasizes formability and aesthetic qualities, 2024 prioritizes mechanical strength and durability under stress.

Key Chemical Composition Differences

6063 aluminum primarily contains magnesium (0.45-0.9%) and silicon (0.2-0.6%), offering excellent corrosion resistance and good weldability, making it ideal for architectural applications. In contrast, 2024 aluminum features a higher copper content (3.8-4.9%) along with magnesium (1.2-1.8%) and manganese (0.3-0.9%), which significantly enhances its strength and fatigue resistance but reduces corrosion resistance. These elemental differences define 6063 as a versatile, corrosion-resistant alloy, whereas 2024 is favored for high-strength aerospace components.

Mechanical Properties Comparison

6063 aluminum features a tensile strength of around 21,000 psi and excellent corrosion resistance, making it ideal for architectural applications, while 2024 aluminum offers a higher tensile strength of approximately 63,000 psi and superior fatigue resistance, preferred in aerospace components. The yield strength of 6063 aluminum averages 19,000 psi, compared to 2024 aluminum's yield strength of about 49,000 psi, reflecting its stronger mechanical performance under stress. Despite 2024 aluminum's greater strength, 6063 aluminum provides better formability and weldability, influencing material choice based on specific mechanical property requirements.

Corrosion Resistance Performance

6063 aluminum offers superior corrosion resistance compared to 2024 aluminum due to its higher magnesium and silicon content, which enhances its natural oxide layer. 2024 aluminum, containing more copper, demonstrates lower corrosion resistance, especially in marine and high-humidity environments without protective coatings. This makes 6063 aluminum the preferred choice for architectural and outdoor applications where exposure to moisture and oxidation is a concern.

Machinability and Workability

6063 aluminum offers superior workability due to its excellent extrusion properties and ease of welding, making it ideal for architectural applications and complex shapes. In contrast, 2024 aluminum exhibits higher machinability with better hardness and strength, commonly used in aerospace components requiring precision machining. The trade-off between 6063's formability and 2024's machinability should guide material selection based on specific manufacturing needs.

Suitability for Welding and Joining

6063 aluminum exhibits superior weldability due to its excellent corrosion resistance and smoother surface finish, making it ideal for applications requiring precise and clean weld joints. In contrast, 2024 aluminum has lower weldability because of its high copper content, which can lead to cracking and reduced corrosion resistance around the weld area. For projects prioritizing strong, durable joints with minimal post-weld treatment, 6063 aluminum is more suitable, whereas 2024 aluminum requires specialized techniques like friction stir welding to improve weld quality.

Common Applications in Industry

6063 Aluminum is widely used in architectural applications, such as window frames, doors, and irrigation tubing, owing to its excellent corrosion resistance and good formability. In contrast, 2024 Aluminum is favored in aerospace and military industries for structural components requiring high strength and fatigue resistance, including aircraft wing structures and fuselage parts. While 6063 excels in aesthetic and lightweight construction projects, 2024 Aluminum is preferred where mechanical performance under stress is critical.

Price and Availability Analysis

6063 aluminum is generally more affordable and widely available due to its common use in architectural and structural applications, offering good corrosion resistance and workability. In contrast, 2024 aluminum commands a higher price because of its superior strength and fatigue resistance, making it preferred for aerospace and military components, but it is less abundant in the market. The cost difference and availability dynamics are influenced by their distinct alloying elements, with 6063 focusing on magnesium and silicon, and 2024 containing higher copper content, impacting production complexity and supply chain factors.

Selecting the Right Aluminum Alloy

Selecting the right aluminum alloy depends on application-specific requirements such as strength, corrosion resistance, and workability; 6063 aluminum excels in architectural and structural uses due to its excellent surface finish and moderate strength, while 2024 aluminum offers superior strength and fatigue resistance ideal for aerospace and high-stress components. 6063 aluminum contains magnesium and silicon, enhancing its extrudability and corrosion resistance, whereas 2024 aluminum, alloyed with copper, prioritizes mechanical performance over corrosion resistance. Understanding these compositional and mechanical differences is crucial for engineers and designers to optimize material choice for durability, machinability, and environmental exposure.

Summary: Which is Better for Your Project?

6063 aluminum offers excellent corrosion resistance and is ideal for architectural applications due to its good extrudability and surface finish. In contrast, 2024 aluminum provides superior strength and fatigue resistance, making it suitable for aerospace and structural projects requiring high mechanical performance. Choosing between 6063 and 2024 aluminum depends on whether your project prioritizes corrosion resistance and aesthetics or strength and durability.

6063 Aluminum vs 2024 Aluminum Infographic

materialdif.com

materialdif.com