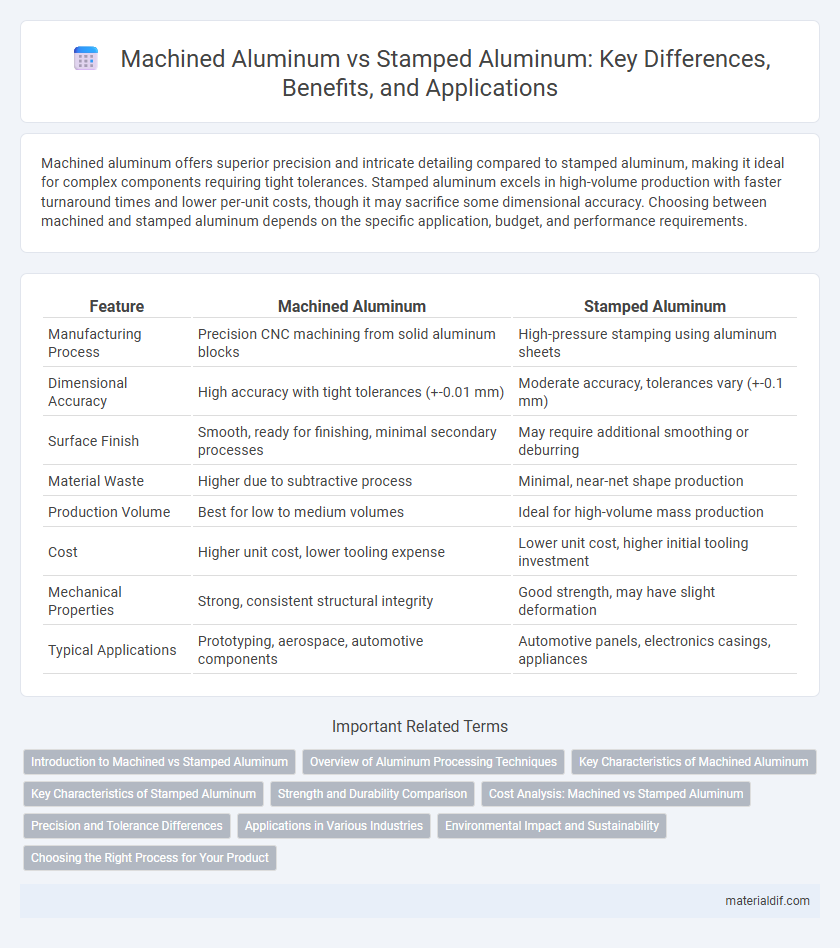

Machined aluminum offers superior precision and intricate detailing compared to stamped aluminum, making it ideal for complex components requiring tight tolerances. Stamped aluminum excels in high-volume production with faster turnaround times and lower per-unit costs, though it may sacrifice some dimensional accuracy. Choosing between machined and stamped aluminum depends on the specific application, budget, and performance requirements.

Table of Comparison

| Feature | Machined Aluminum | Stamped Aluminum |

|---|---|---|

| Manufacturing Process | Precision CNC machining from solid aluminum blocks | High-pressure stamping using aluminum sheets |

| Dimensional Accuracy | High accuracy with tight tolerances (+-0.01 mm) | Moderate accuracy, tolerances vary (+-0.1 mm) |

| Surface Finish | Smooth, ready for finishing, minimal secondary processes | May require additional smoothing or deburring |

| Material Waste | Higher due to subtractive process | Minimal, near-net shape production |

| Production Volume | Best for low to medium volumes | Ideal for high-volume mass production |

| Cost | Higher unit cost, lower tooling expense | Lower unit cost, higher initial tooling investment |

| Mechanical Properties | Strong, consistent structural integrity | Good strength, may have slight deformation |

| Typical Applications | Prototyping, aerospace, automotive components | Automotive panels, electronics casings, appliances |

Introduction to Machined vs Stamped Aluminum

Machined aluminum is produced by removing material from a solid aluminum block using precision CNC machines, resulting in highly accurate and complex parts with tight tolerances. Stamped aluminum, on the other hand, is formed by pressing flat aluminum sheets into desired shapes through high-speed stamping processes, ideal for high-volume production with consistent dimensions. Choosing between machined and stamped aluminum depends on factors such as part complexity, production volume, and required mechanical properties.

Overview of Aluminum Processing Techniques

Machined aluminum involves the precise removal of material using tools like CNC machines, enabling complex shapes and tight tolerances ideal for aerospace and automotive components. Stamped aluminum, produced by pressing sheets into molds, offers high-volume efficiency and consistent, lightweight parts commonly used in packaging and consumer electronics. Both techniques optimize aluminum's strength-to-weight ratio but differ in production speed, cost, and design flexibility.

Key Characteristics of Machined Aluminum

Machined aluminum is characterized by its high precision, smooth surface finish, and ability to achieve complex geometries with tight tolerances. It offers superior strength and durability due to the subtractive manufacturing process that preserves material integrity. This makes machined aluminum ideal for applications requiring intricate details and structural reliability.

Key Characteristics of Stamped Aluminum

Stamped aluminum offers high production speed and cost efficiency by using dies to rapidly form sheets into precise shapes, making it ideal for large-scale manufacturing. It provides excellent dimensional consistency and repeatability, with the ability to produce complex geometries and fine details not easily achieved through machining. This process results in lightweight components with good strength and minimal material waste, enhancing sustainability in automotive and aerospace applications.

Strength and Durability Comparison

Machined aluminum exhibits superior strength and durability due to its solid, uniform structure achieved through precision cutting from a single block, minimizing internal stresses and defects. Stamped aluminum, formed by pressing sheets into shape, often contains microstructural weaknesses and residual stresses that reduce its load-bearing capacity and resistance to fatigue. For applications demanding high-strength and long-lasting performance, machined aluminum components offer enhanced structural integrity and longevity.

Cost Analysis: Machined vs Stamped Aluminum

Machined aluminum typically incurs higher costs due to the precision and labor-intensive processes involved, making it suitable for low-volume or highly detailed parts. Stamped aluminum offers significant cost savings in large-scale production because of faster cycle times and reduced material waste. Evaluating the upfront tooling investments against per-unit costs is essential to determine the most cost-effective manufacturing method for specific aluminum component requirements.

Precision and Tolerance Differences

Machined aluminum offers superior precision and tighter tolerances compared to stamped aluminum due to its CNC-controlled subtractive manufacturing process. Stamped aluminum, produced through high-pressure dies, generally exhibits broader tolerance ranges and less detailed features, making it suitable for high-volume, lower-precision applications. The choice between machined and stamped aluminum hinges on required dimensional accuracy, with machined parts often achieving tolerances within microns, whereas stamped components typically maintain tolerances in the range of +-0.1 to +-0.5 mm.

Applications in Various Industries

Machined aluminum offers precise tolerances and complex geometries, making it ideal for aerospace components, medical devices, and automotive parts requiring high strength and detailed finishes. Stamped aluminum excels in high-volume production with consistent shapes, commonly used in electronics housings, automotive body panels, and consumer appliances where cost efficiency and speed are critical. Both methods optimize aluminum's lightweight and corrosion-resistant properties to meet diverse industrial demands.

Environmental Impact and Sustainability

Machined aluminum typically generates more waste due to the subtractive manufacturing process, whereas stamped aluminum benefits from material efficiency by shaping sheets with minimal scrap. The energy consumption of machining is generally higher compared to stamping, impacting the carbon footprint of production. Recyclability remains high for both forms, but stamped aluminum's lower processing energy offers a more sustainable choice for eco-conscious manufacturing.

Choosing the Right Process for Your Product

Machined aluminum offers superior precision and customization, ideal for complex parts requiring tight tolerances and detailed finishes, whereas stamped aluminum excels in high-volume production with faster turnaround and cost efficiency. Selecting the right process depends on factors like production volume, design complexity, and budget constraints. Understanding the strengths of machined versus stamped aluminum ensures optimal performance, durability, and cost-effectiveness in your product.

Machined Aluminum vs Stamped Aluminum Infographic

materialdif.com

materialdif.com