Extruded aluminum offers superior strength and design flexibility by forcing heated aluminum through a shaped die, ideal for complex cross-sections and custom profiles. Rolled aluminum involves passing a heated slab through rollers to create thin sheets or plates, providing uniform thickness and smooth surfaces suited for applications requiring lightweight and corrosion resistance. Choosing extruded or rolled aluminum depends on the specific structural requirements and product design complexity.

Table of Comparison

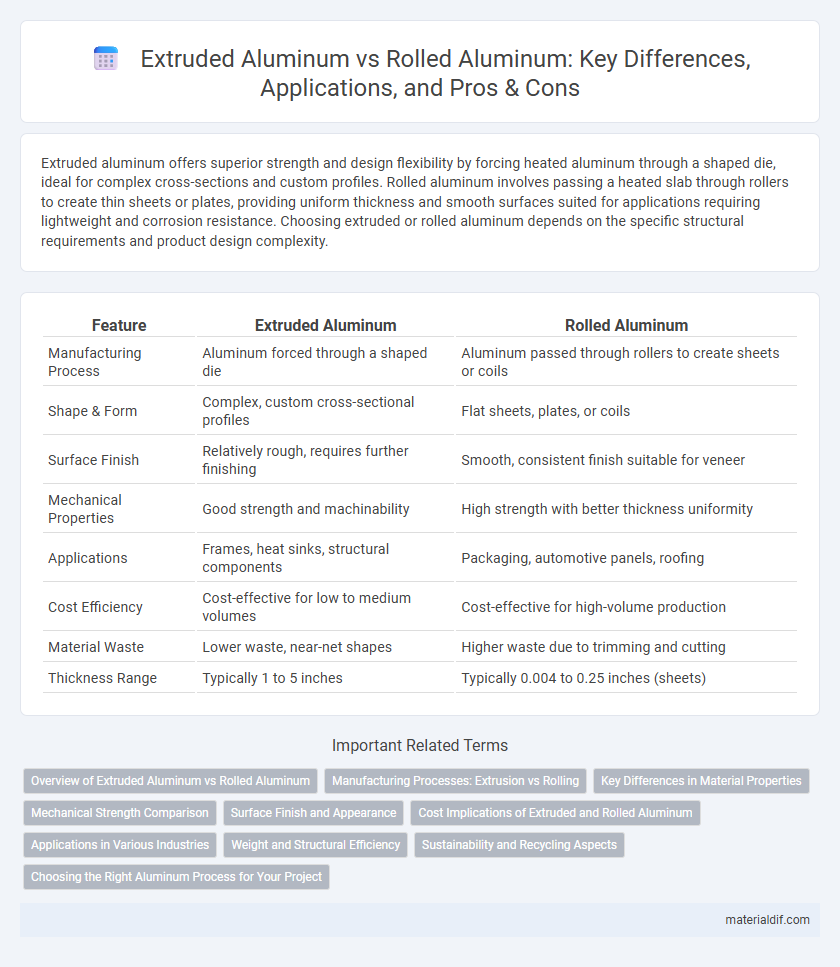

| Feature | Extruded Aluminum | Rolled Aluminum |

|---|---|---|

| Manufacturing Process | Aluminum forced through a shaped die | Aluminum passed through rollers to create sheets or coils |

| Shape & Form | Complex, custom cross-sectional profiles | Flat sheets, plates, or coils |

| Surface Finish | Relatively rough, requires further finishing | Smooth, consistent finish suitable for veneer |

| Mechanical Properties | Good strength and machinability | High strength with better thickness uniformity |

| Applications | Frames, heat sinks, structural components | Packaging, automotive panels, roofing |

| Cost Efficiency | Cost-effective for low to medium volumes | Cost-effective for high-volume production |

| Material Waste | Lower waste, near-net shapes | Higher waste due to trimming and cutting |

| Thickness Range | Typically 1 to 5 inches | Typically 0.004 to 0.25 inches (sheets) |

Overview of Extruded Aluminum vs Rolled Aluminum

Extruded aluminum is produced by forcing heated aluminum through a shaped die, creating complex cross-sectional profiles with high strength and precise dimensions, ideal for architectural and automotive applications. Rolled aluminum is manufactured by passing aluminum ingots through rollers to produce flat sheets or plates, offering uniform thickness and smooth surfaces suitable for packaging, construction, and aerospace industries. Extrusion allows for customized shapes while rolling provides extensive surface area and consistent thickness for structural uses.

Manufacturing Processes: Extrusion vs Rolling

Extruded aluminum is produced by forcing heated aluminum billet through a shaped die to create complex cross-sectional profiles, allowing precise control over dimensions and customized designs. Rolled aluminum involves passing aluminum slabs through a series of rollers to reduce thickness and produce flat sheets or coils, optimizing surface finish and mechanical properties. Extrusion offers greater versatility for intricate shapes, while rolling is more efficient for high-volume production of uniform flat products.

Key Differences in Material Properties

Extruded aluminum features a uniform microstructure due to the controlled process of forcing the alloy through a die, resulting in higher tensile strength and improved mechanical properties along the extrusion direction. Rolled aluminum, produced by compressing the alloy between rollers, exhibits enhanced surface finish and dimensional accuracy but may have anisotropic properties with reduced strength perpendicular to the rolling direction. The key differences in material properties between extruded and rolled aluminum influence their suitability for structural applications, where extrusions provide superior strength-to-weight ratios and rolled products offer better formability and surface characteristics.

Mechanical Strength Comparison

Extruded aluminum exhibits superior mechanical strength compared to rolled aluminum due to its continuous grain flow, which enhances structural integrity and resistance to deformation. The extrusion process aligns the metal's grain structure along the profile, resulting in increased tensile strength and improved load-bearing capabilities. Rolled aluminum, while offering uniform thickness and surface finish, generally has slightly lower strength due to its grain orientation being less optimized for mechanical stress.

Surface Finish and Appearance

Extruded aluminum typically features a smoother, more uniform surface finish due to the controlled extrusion process that minimizes surface imperfections and allows for intricate shapes with consistent textures. Rolled aluminum exhibits a different aesthetic with a slightly textured surface characterized by fine grain patterns and potential minor surface irregularities from the rolling process. The appearance of extruded aluminum is generally preferred for applications requiring sleek, polished looks, while rolled aluminum's texture offers enhanced grip and visual interest for functional or decorative purposes.

Cost Implications of Extruded and Rolled Aluminum

Extruded aluminum typically incurs higher production costs due to its complex shaping process and slower production speeds, which result in increased energy consumption and tooling expenses. Rolled aluminum benefits from faster manufacturing rates and more efficient material usage, leading to lower overall costs, especially for large-volume applications such as sheets and foils. Budget considerations often favor rolled aluminum for large, flat parts, while extruded aluminum is preferred when intricate profiles justify the additional expense.

Applications in Various Industries

Extruded aluminum offers superior design flexibility and strength, making it ideal for automotive frames, aerospace components, and construction frameworks where complex cross-sections are required. Rolled aluminum provides excellent surface finishes and consistent thickness, preferred in packaging, foil production, and heat exchanger panels for the electronics and food industries. Both forms optimize aluminum's lightweight, corrosion resistance, and conductivity for diverse industrial applications.

Weight and Structural Efficiency

Extruded aluminum offers higher structural efficiency due to its ability to create complex cross-sectional shapes that optimize strength-to-weight ratios, making it ideal for lightweight applications. Rolled aluminum, while typically thinner and more uniform, often provides less design flexibility but can achieve weight savings in large, flat components. Choosing extruded aluminum enhances load-bearing performance per unit weight, whereas rolled aluminum excels in applications requiring consistent thickness and surface finish.

Sustainability and Recycling Aspects

Extruded aluminum offers enhanced material efficiency due to precise shaping, resulting in less scrap and lower energy consumption during production compared to rolled aluminum. Rolled aluminum, although offering excellent surface finish and uniform thickness, often involves higher energy use and generates more waste during processing. Both forms are highly recyclable, retaining aluminum's inherent sustainability benefits, but extruded aluminum's reduced material waste and energy footprint contribute to a more eco-friendly lifecycle.

Choosing the Right Aluminum Process for Your Project

Extruded aluminum offers superior strength and intricate cross-sectional shapes, making it ideal for structural components and custom profiles, while rolled aluminum provides uniform thickness and smooth finishes suited for sheets and foils. Selecting the right aluminum process depends on factors such as required mechanical properties, design complexity, and manufacturing volume. Understanding the benefits of extrusion's dimensional versatility versus rolling's efficiency in producing large surface areas ensures optimal material performance for your project needs.

Extruded Aluminum vs Rolled Aluminum Infographic

materialdif.com

materialdif.com