T5 temper aluminum is artificially aged after being cooled from an elevated temperature, providing moderate strength and good machinability, making it suitable for applications requiring a balance of performance and cost. T6 temper aluminum undergoes solution heat treatment followed by artificial aging, resulting in higher strength and improved corrosion resistance compared to T5, ideal for structural components and high-stress environments. Choosing between T5 and T6 tempers depends on the specific mechanical requirements and environmental conditions of the application.

Table of Comparison

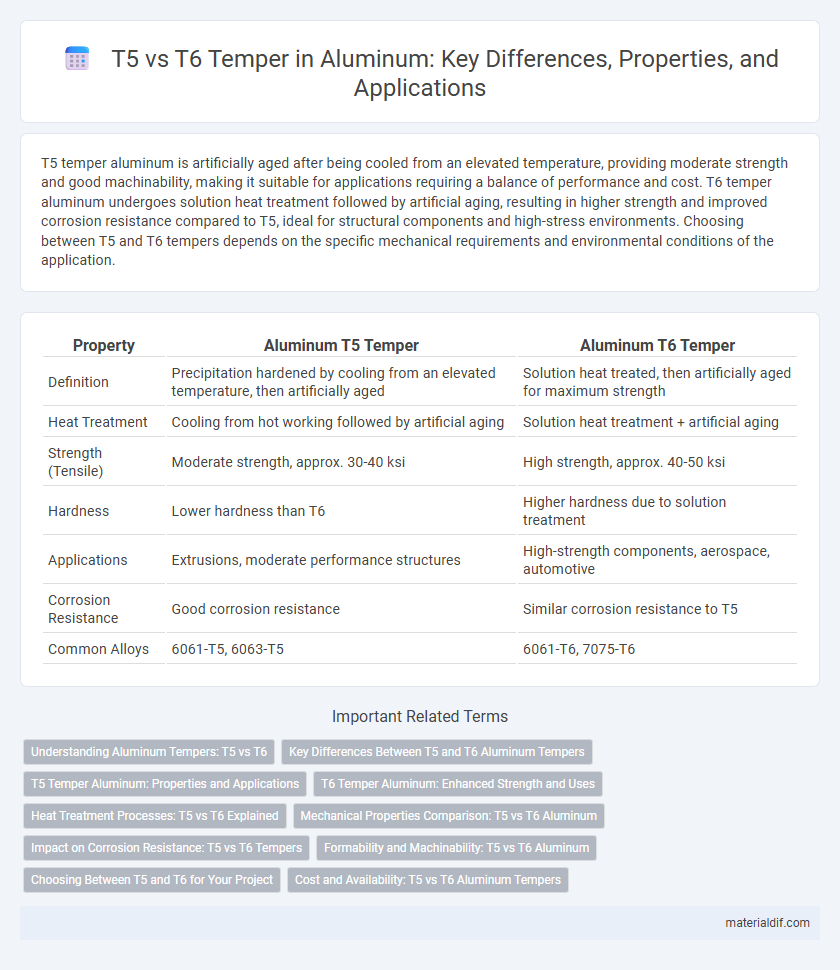

| Property | Aluminum T5 Temper | Aluminum T6 Temper |

|---|---|---|

| Definition | Precipitation hardened by cooling from an elevated temperature, then artificially aged | Solution heat treated, then artificially aged for maximum strength |

| Heat Treatment | Cooling from hot working followed by artificial aging | Solution heat treatment + artificial aging |

| Strength (Tensile) | Moderate strength, approx. 30-40 ksi | High strength, approx. 40-50 ksi |

| Hardness | Lower hardness than T6 | Higher hardness due to solution treatment |

| Applications | Extrusions, moderate performance structures | High-strength components, aerospace, automotive |

| Corrosion Resistance | Good corrosion resistance | Similar corrosion resistance to T5 |

| Common Alloys | 6061-T5, 6063-T5 | 6061-T6, 7075-T6 |

Understanding Aluminum Tempers: T5 vs T6

T5 temper aluminum is solution heat-treated and then artificially aged to achieve a moderate level of strength, making it suitable for applications requiring good machinability and corrosion resistance. T6 temper undergoes a more rigorous solution heat treatment followed by a precise artificial aging process, resulting in higher tensile strength and improved mechanical properties. Selecting between T5 and T6 tempers depends on the balance needed between strength, ductility, and performance in structural and automotive components.

Key Differences Between T5 and T6 Aluminum Tempers

T5 aluminum temper is characterized by being cooled from an elevated temperature shaping process and then artificially aged to achieve moderate strength, while T6 aluminum temper undergoes solution heat treatment followed by artificial aging to attain higher strength and improved mechanical properties. The key difference lies in the heat treatment process, where T6 offers better tensile strength, hardness, and stress resistance compared to T5, making it suitable for more demanding structural applications. T5 is often used for parts requiring moderate strength with good corrosion resistance, whereas T6 is preferred in aerospace and automotive industries requiring maximum performance and durability.

T5 Temper Aluminum: Properties and Applications

T5 temper aluminum undergoes artificial aging after being cooled from an elevated temperature shaping process, resulting in moderate strength and excellent corrosion resistance. This temper enhances machinability and is commonly used in automotive parts, architectural components, and electronic enclosures where a balance between strength and ductility is crucial. T5 aluminum offers improved stability and surface finish compared to other tempers, making it ideal for applications requiring a smooth, durable surface with good mechanical properties.

T6 Temper Aluminum: Enhanced Strength and Uses

T6 temper aluminum undergoes solution heat treatment followed by artificial aging, resulting in significantly enhanced mechanical strength and improved corrosion resistance compared to T5 temper. This makes T6 aluminum ideal for high-stress applications such as aerospace components, automotive parts, and structural framing where durability and performance are critical. The precise control over aging conditions in T6 temper optimizes the alloy's microstructure, delivering superior hardness and tensile strength.

Heat Treatment Processes: T5 vs T6 Explained

T5 temper involves cooling aluminum from an elevated temperature shaping process followed by artificial aging, enhancing strength without full solution heat treatment. T6 temper includes solution heat treatment, rapid quenching, and artificial aging, resulting in maximum strength and improved mechanical properties. The key difference lies in T6's solution treatment step, which dissolves soluble phases, allowing precipitation hardening during aging for superior hardness and durability.

Mechanical Properties Comparison: T5 vs T6 Aluminum

T5 tempered aluminum undergoes artificial aging after being cooled from an elevated temperature shaping process, resulting in moderate strength and improved machinability. T6 temper involves solution heat treatment followed by artificial aging, yielding higher tensile strength, better hardness, and increased fatigue resistance compared to T5. Mechanical properties of T6 aluminum typically exceed those of T5, making T6 ideal for applications demanding enhanced structural performance.

Impact on Corrosion Resistance: T5 vs T6 Tempers

T5 temper aluminum is artificially aged after being cooled from an elevated temperature shaping process, resulting in moderate strength with improved corrosion resistance due to less internal stress. T6 temper involves solution heat treatment followed by artificial aging, which enhances strength but can increase susceptibility to corrosion because of increased residual stresses and microstructural changes. Comparing corrosion resistance, T5 temper aluminum generally exhibits better performance in corrosive environments than T6, making it preferable for applications requiring higher resistance to environmental degradation.

Formability and Machinability: T5 vs T6 Aluminum

T5 aluminum temper offers superior formability due to its lower hardness and increased ductility, making it ideal for complex bending and shaping applications. In contrast, T6 aluminum delivers enhanced machinability because of its higher strength and hardness after solution heat treatment and artificial aging, which allows for precision machining with less tool wear. Choosing between T5 and T6 depends on the balance needed between ease of forming and efficiency in machining for the intended manufacturing process.

Choosing Between T5 and T6 for Your Project

T5 temper involves artificial aging of aluminum after it has been cooled from an elevated temperature shaping process, resulting in moderate strength and good machinability. T6 temper features solution heat treatment followed by artificial aging, delivering higher strength and improved fatigue resistance ideal for structural applications. Selecting between T5 and T6 depends on the required mechanical properties and performance criteria of your project, with T6 preferred for maximum strength and T5 offering a balance between strength and workability.

Cost and Availability: T5 vs T6 Aluminum Tempers

T5 aluminum temper generally offers lower production costs due to its simpler heat treatment process, making it more economically viable for large-scale manufacturing. T6 aluminum, involving solution heat treatment and artificial aging, typically incurs higher expenses but provides superior mechanical properties, justifying its premium price in critical applications. Availability for T5 aluminum is often greater in standard extrusions, whereas T6 aluminum may require specialized processing, affecting lead times and supply chain accessibility.

T5 temper vs T6 temper Infographic

materialdif.com

materialdif.com