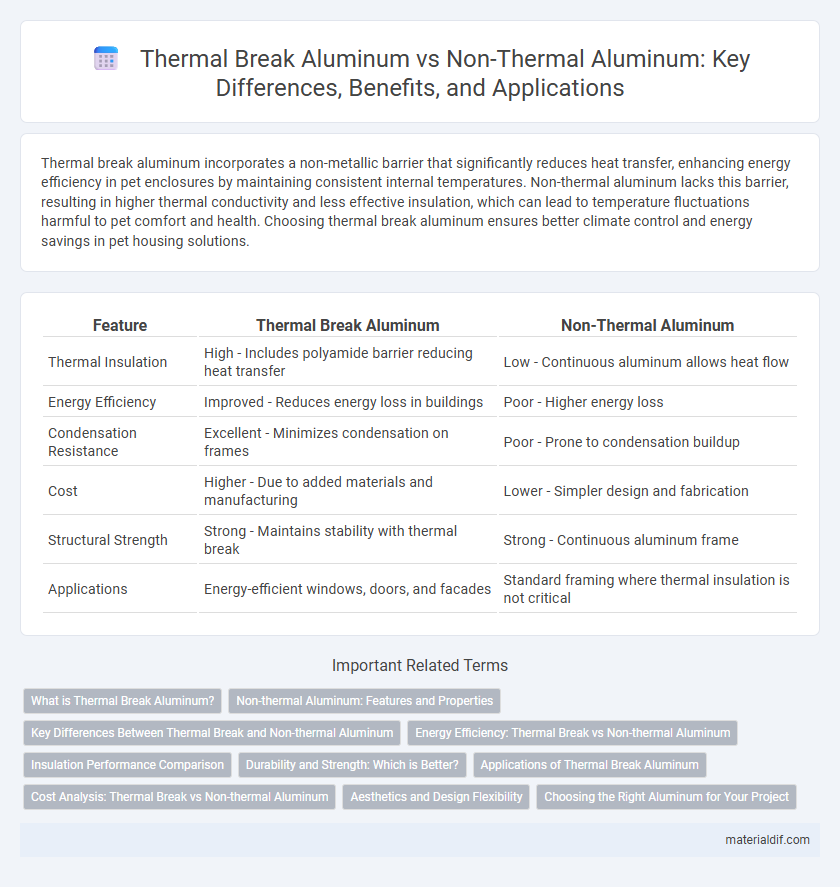

Thermal break aluminum incorporates a non-metallic barrier that significantly reduces heat transfer, enhancing energy efficiency in pet enclosures by maintaining consistent internal temperatures. Non-thermal aluminum lacks this barrier, resulting in higher thermal conductivity and less effective insulation, which can lead to temperature fluctuations harmful to pet comfort and health. Choosing thermal break aluminum ensures better climate control and energy savings in pet housing solutions.

Table of Comparison

| Feature | Thermal Break Aluminum | Non-Thermal Aluminum |

|---|---|---|

| Thermal Insulation | High - Includes polyamide barrier reducing heat transfer | Low - Continuous aluminum allows heat flow |

| Energy Efficiency | Improved - Reduces energy loss in buildings | Poor - Higher energy loss |

| Condensation Resistance | Excellent - Minimizes condensation on frames | Poor - Prone to condensation buildup |

| Cost | Higher - Due to added materials and manufacturing | Lower - Simpler design and fabrication |

| Structural Strength | Strong - Maintains stability with thermal break | Strong - Continuous aluminum frame |

| Applications | Energy-efficient windows, doors, and facades | Standard framing where thermal insulation is not critical |

What is Thermal Break Aluminum?

Thermal break aluminum incorporates a non-metallic insulating material between the inner and outer aluminum profiles, significantly reducing heat transfer and improving energy efficiency in building applications. This design minimizes condensation and enhances thermal performance compared to non-thermal aluminum, which conducts heat directly through the frame. Thermal break aluminum is essential in modern construction for maintaining indoor temperature control and complying with energy codes.

Non-thermal Aluminum: Features and Properties

Non-thermal aluminum features a single continuous metal profile without insulation barriers, providing excellent structural strength and conductivity. It is commonly used in applications where thermal insulation is less critical, such as interior framing and decorative elements. This type of aluminum offers cost-effectiveness and durability but lacks the energy efficiency benefits of thermal break aluminum.

Key Differences Between Thermal Break and Non-thermal Aluminum

Thermal break aluminum incorporates a non-metallic insulating barrier between aluminum profiles, significantly reducing heat transfer and improving energy efficiency compared to non-thermal aluminum, which lacks this insulation and conducts heat more readily. Key differences include enhanced thermal performance, lower condensation risk, and better indoor climate control with thermal break aluminum. Non-thermal aluminum is typically more cost-effective but less efficient in preventing heat loss or gain.

Energy Efficiency: Thermal Break vs Non-thermal Aluminum

Thermal break aluminum significantly improves energy efficiency by incorporating an insulating polymer barrier between the inner and outer aluminum sections, reducing thermal conductivity and minimizing heat transfer. Non-thermal aluminum lacks this barrier, leading to higher heat loss or gain, which decreases overall energy performance in building envelopes. Buildings using thermal break aluminum experience lower heating and cooling costs, enhancing sustainability and comfort compared to non-thermal aluminum systems.

Insulation Performance Comparison

Thermal break aluminum incorporates a polyamide barrier between the interior and exterior aluminum frames, significantly reducing heat transfer and enhancing insulation performance compared to non-thermal aluminum. Non-thermal aluminum lacks this insulating barrier, resulting in higher thermal conductivity that allows for considerable heat loss or gain, which diminishes energy efficiency. As a result, thermal break aluminum systems are preferred in energy-conscious architectural applications for superior thermal insulation and improved indoor climate control.

Durability and Strength: Which is Better?

Thermal break aluminum incorporates a polymer barrier between its interior and exterior aluminum profiles, enhancing thermal insulation without significantly compromising structural strength. Non-thermal aluminum offers superior durability and rigidity due to its uninterrupted metal composition, making it ideal for applications requiring maximum load-bearing capacity. For long-term structural integrity in demanding environments, non-thermal aluminum is often preferred, while thermal break aluminum balances moderate strength with improved energy efficiency.

Applications of Thermal Break Aluminum

Thermal break aluminum is essential in architectural applications requiring enhanced energy efficiency, such as window frames, curtain walls, and doors, by significantly reducing heat transfer and minimizing condensation. Its use in building envelopes helps achieve better thermal insulation standards, contributing to green building certifications like LEED. Unlike non-thermal aluminum, thermal break aluminum improves indoor comfort and energy savings in both commercial and residential construction projects.

Cost Analysis: Thermal Break vs Non-thermal Aluminum

Thermal break aluminum typically incurs higher initial costs due to the integration of insulating materials that enhance energy efficiency and reduce heat transfer. Non-thermal aluminum is generally more affordable upfront but may lead to increased energy expenses over time because of less effective thermal regulation. Long-term cost analysis often favors thermal break aluminum for projects prioritizing sustainability and lower heating and cooling bills.

Aesthetics and Design Flexibility

Thermal break aluminum incorporates a plastic section between metal profiles, enhancing insulation while allowing sleek, narrow frames that elevate modern architectural aesthetics. Non-thermal aluminum offers greater design flexibility with thinner profiles but lacks the energy efficiency and condensation control provided by thermal breaks. Choosing thermal break aluminum enables designers to achieve both high performance and contemporary visual appeal in facade and window systems.

Choosing the Right Aluminum for Your Project

Thermal break aluminum features an insulating barrier that significantly reduces heat transfer, making it ideal for energy-efficient buildings and projects requiring superior thermal performance. Non-thermal aluminum lacks this barrier, offering higher conductivity and often lower cost, suitable for applications where insulation is less critical. Choosing the right aluminum involves assessing project requirements for energy efficiency, climate conditions, and budget constraints to select either thermal break aluminum for enhanced insulation or non-thermal aluminum for cost-effective durability.

Thermal Break Aluminum vs Non-thermal Aluminum Infographic

materialdif.com

materialdif.com