Drawn aluminum undergoes a process where the metal is pulled through a die to achieve precise shapes and enhanced strength, making it ideal for manufacturing tubes, rods, and intricate components. Rolled aluminum is produced by passing the metal between rollers to create sheets or plates with uniform thickness, commonly used in construction, packaging, and automotive industries. The choice between drawn and rolled aluminum depends on the required mechanical properties and final application, as drawn aluminum offers superior tensile strength while rolled aluminum provides flexibility and surface finish options.

Table of Comparison

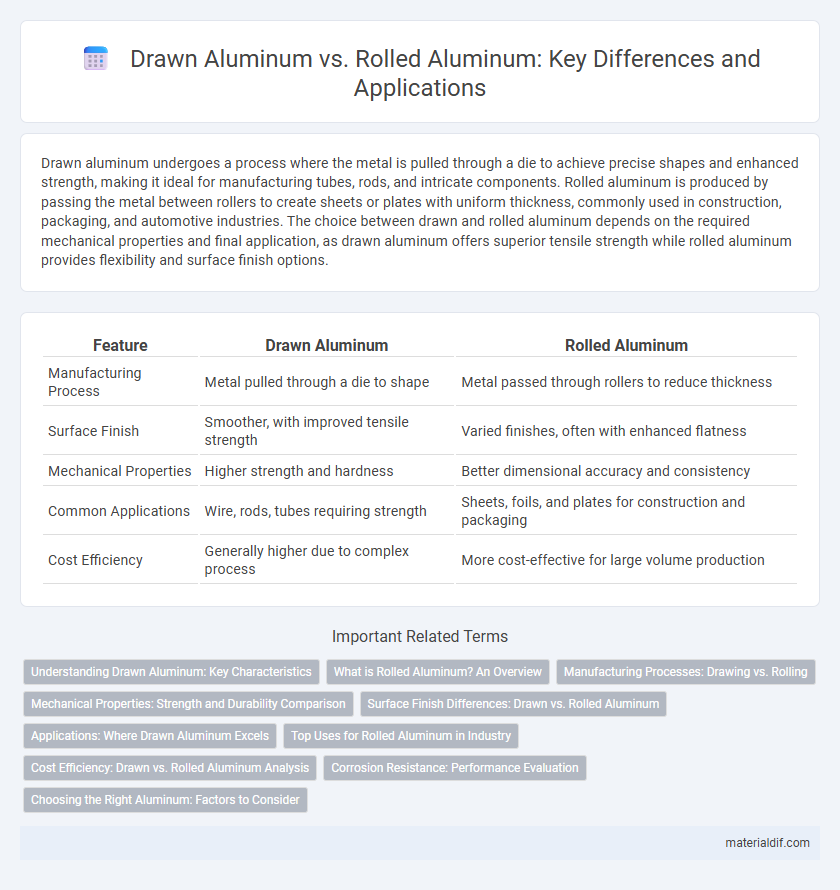

| Feature | Drawn Aluminum | Rolled Aluminum |

|---|---|---|

| Manufacturing Process | Metal pulled through a die to shape | Metal passed through rollers to reduce thickness |

| Surface Finish | Smoother, with improved tensile strength | Varied finishes, often with enhanced flatness |

| Mechanical Properties | Higher strength and hardness | Better dimensional accuracy and consistency |

| Common Applications | Wire, rods, tubes requiring strength | Sheets, foils, and plates for construction and packaging |

| Cost Efficiency | Generally higher due to complex process | More cost-effective for large volume production |

Understanding Drawn Aluminum: Key Characteristics

Drawn aluminum is produced by pulling the metal through a die, which enhances its tensile strength and dimensional accuracy compared to rolled aluminum. It typically exhibits a smoother surface finish and tighter tolerances, making it ideal for precision applications such as aerospace components and electrical conductors. The cold working process involved in drawing increases the metal's hardness and resistance to wear, distinguishing it from the more malleable and thicker profiles found in rolled aluminum products.

What is Rolled Aluminum? An Overview

Rolled aluminum is produced by passing aluminum alloy sheets or plates through a series of rollers to reduce thickness and improve mechanical properties. This process enhances surface smoothness, strength, and uniformity, making it ideal for applications like automotive panels and aircraft skins. Compared to drawn aluminum, rolled aluminum offers superior dimensional accuracy and surface finish for large-scale manufacturing.

Manufacturing Processes: Drawing vs. Rolling

Drawn aluminum is produced by pulling a heated aluminum billet through a die to reduce its diameter, which enhances tensile strength and surface finish due to work hardening. Rolled aluminum involves passing heated aluminum slabs through rollers to form sheets or plates, improving grain structure uniformity and thickness consistency. Drawing typically yields more precise, smaller cross-sections ideal for tubing and wire, while rolling is suited for producing larger, flat products such as sheets and coils.

Mechanical Properties: Strength and Durability Comparison

Drawn aluminum typically exhibits higher tensile strength and improved fatigue resistance due to its unidirectional grain structure formed during the drawing process. Rolled aluminum, while offering excellent ductility and toughness, often shows more isotropic mechanical properties but slightly lower yield strength compared to drawn aluminum. The enhanced strength and durability of drawn aluminum make it ideal for applications requiring precise dimensional tolerances and high mechanical performance.

Surface Finish Differences: Drawn vs. Rolled Aluminum

Drawn aluminum features a smoother, more uniform surface finish due to the controlled tension applied during the drawing process, which enhances its aesthetic appeal and reduces surface defects. Rolled aluminum typically exhibits a flatter, more consistent texture with slight directional grain patterns resulting from the compressive forces in rolling, making it ideal for applications requiring precise thickness and flatness. Surface finish differences impact corrosion resistance and paint adhesion, with drawn aluminum often preferred for decorative uses while rolled aluminum suits structural or industrial purposes.

Applications: Where Drawn Aluminum Excels

Drawn aluminum exhibits superior strength and enhanced surface finish, making it ideal for precision applications such as aerospace components, automotive parts, and electrical connectors. Its uniform grain structure improves mechanical properties and corrosion resistance, benefiting architectural elements and intricate machinery. Industries requiring tight tolerances and high-quality finishes frequently select drawn aluminum over rolled alternatives for optimal performance.

Top Uses for Rolled Aluminum in Industry

Rolled aluminum is extensively used in industries requiring flat and uniform sheets, such as automotive manufacturing for body panels and aerospace for structural components. Its enhanced surface finish and precise thickness control make it ideal for packaging, including beverage cans and foil, as well as construction materials like roofing and siding. The versatility of rolled aluminum supports electrical applications, heat exchangers, and decorative purposes due to its strength, lightweight properties, and corrosion resistance.

Cost Efficiency: Drawn vs. Rolled Aluminum Analysis

Drawn aluminum exhibits higher cost efficiency in applications requiring precise dimensions and superior surface finish due to minimal need for secondary machining, reducing overall production expenses. Rolled aluminum offers advantages in large-scale manufacturing with lower material waste and faster throughput, making it more economical for bulk structural components. Analyzing total lifecycle costs reveals drawn aluminum is preferable for precision parts, while rolled aluminum is optimal for high-volume, cost-sensitive projects.

Corrosion Resistance: Performance Evaluation

Drawn aluminum typically exhibits higher corrosion resistance due to the reduced presence of surface defects and a more uniform oxide layer, enhancing its durability in harsh environments. Rolled aluminum, while offering excellent mechanical strength, may have microstructural inconsistencies from the rolling process that can affect corrosion behavior. Evaluating performance in marine and industrial atmospheres, drawn aluminum consistently outperforms rolled aluminum in resisting pitting and galvanic corrosion.

Choosing the Right Aluminum: Factors to Consider

Choosing the right aluminum depends on the specific application requirements, where drawn aluminum offers superior strength and dimensional precision due to its manufacturing process, making it ideal for structural components and intricate profiles. Rolled aluminum provides enhanced surface finish and isotropic mechanical properties, suitable for large sheet applications such as automotive panels and packaging. Consider factors like mechanical strength, surface finish, dimensional tolerances, and intended use environment to determine the best aluminum type for optimal performance and cost-efficiency.

Drawn Aluminum vs Rolled Aluminum Infographic

materialdif.com

materialdif.com