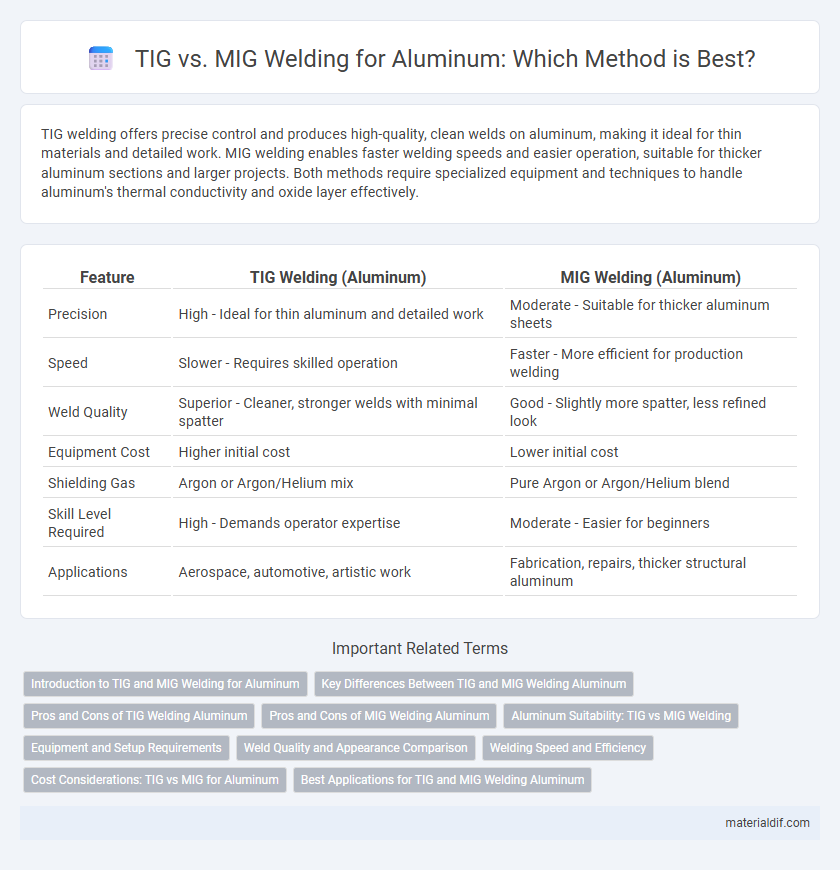

TIG welding offers precise control and produces high-quality, clean welds on aluminum, making it ideal for thin materials and detailed work. MIG welding enables faster welding speeds and easier operation, suitable for thicker aluminum sections and larger projects. Both methods require specialized equipment and techniques to handle aluminum's thermal conductivity and oxide layer effectively.

Table of Comparison

| Feature | TIG Welding (Aluminum) | MIG Welding (Aluminum) |

|---|---|---|

| Precision | High - Ideal for thin aluminum and detailed work | Moderate - Suitable for thicker aluminum sheets |

| Speed | Slower - Requires skilled operation | Faster - More efficient for production welding |

| Weld Quality | Superior - Cleaner, stronger welds with minimal spatter | Good - Slightly more spatter, less refined look |

| Equipment Cost | Higher initial cost | Lower initial cost |

| Shielding Gas | Argon or Argon/Helium mix | Pure Argon or Argon/Helium blend |

| Skill Level Required | High - Demands operator expertise | Moderate - Easier for beginners |

| Applications | Aerospace, automotive, artistic work | Fabrication, repairs, thicker structural aluminum |

Introduction to TIG and MIG Welding for Aluminum

TIG welding for aluminum uses a non-consumable tungsten electrode and requires a shielding gas, typically argon, creating precise, high-quality welds ideal for thin materials and intricate joints. MIG welding employs a consumable wire electrode with a continuous feed and is faster, suitable for thicker aluminum sections and production environments. Both techniques demand clean aluminum surfaces and proper gas flow to prevent oxidation and ensure strong weld integrity.

Key Differences Between TIG and MIG Welding Aluminum

TIG welding aluminum uses a non-consumable tungsten electrode and requires filler rod separately, providing superior precision and control for thin or complex aluminum components. MIG welding aluminum employs a consumable wire electrode fed continuously, enabling faster welds and better suitability for thicker aluminum materials or production environments. TIG offers cleaner, high-quality welds with less spatter, while MIG welding excels in speed and ease of use, particularly in large-scale aluminum fabrication.

Pros and Cons of TIG Welding Aluminum

TIG welding Aluminum offers precise control and produces high-quality, clean welds with minimal spatter, making it ideal for thin or intricate aluminum components. However, TIG welding requires greater skill and slower welding speed compared to MIG, leading to longer production times and potentially higher labor costs. Its ability to create stronger, more aesthetically pleasing joints makes TIG welds preferred in aerospace and automotive industries despite these challenges.

Pros and Cons of MIG Welding Aluminum

MIG welding aluminum offers faster welding speeds and is generally easier for beginners due to continuous wire feed and less technique sensitivity. However, it requires high-quality shielding gas and careful control of heat input to prevent burn-through and porosity. MIG welding aluminum is less precise than TIG, making it less suitable for thin sheets or detailed welds despite its efficiency on thicker aluminum sections.

Aluminum Suitability: TIG vs MIG Welding

TIG welding offers superior control and precision, making it ideal for thin aluminum sheets and detailed welds with a clean finish. MIG welding, while faster and easier to master, suits thicker aluminum sections and production environments requiring high deposition rates. Both methods require specialized equipment and shielding gas to prevent oxidation and ensure strong, durable welds in aluminum applications.

Equipment and Setup Requirements

TIG welding aluminum requires a high-precision setup, including a constant current power supply, a tungsten electrode, and an inert gas like pure argon for shielding, providing superior control over heat input and weld quality. MIG welding aluminum uses a constant voltage power supply with a spool gun or push-pull feeder system to handle the soft aluminum wire, necessitating less operator skill but more complex equipment setup to prevent wire feeding issues. Both methods demand clean aluminum surfaces and proper gas flow settings, but TIG welding setups prioritize intricate control, while MIG setups emphasize efficient wire feeding mechanisms.

Weld Quality and Appearance Comparison

TIG welding aluminum produces cleaner, more precise welds with superior control over heat input, resulting in a smoother, aesthetically pleasing finish and minimal oxidation. MIG welding offers faster weld speeds suitable for thicker aluminum sections but often leads to spatter and less refined weld appearance. For high-quality, visually appealing aluminum welds, TIG is preferred due to its ability to create uniform, crack-resistant joints with excellent bead consistency.

Welding Speed and Efficiency

TIG welding offers precise control for aluminum with cleaner welds but operates at a slower speed, making it ideal for detailed or thin material applications. MIG welding provides faster welding speeds and higher deposition rates on aluminum, enhancing efficiency for thicker sections and large-scale projects. Efficiency in aluminum welding depends on balancing the required weld quality with production speed, where MIG excels in volume, while TIG delivers superior finish quality.

Cost Considerations: TIG vs MIG for Aluminum

TIG welding for aluminum typically involves higher costs due to slower welding speeds and the need for specialized inert gas mixtures like pure argon, while MIG welding offers faster deposition rates and increased efficiency, lowering labor expenses. Equipment for TIG welding tends to be more expensive and requires more precise skill, impacting overall operational costs compared to MIG, which uses less complex machinery and consumables. When factoring in cost considerations for aluminum welding, MIG welding is generally preferred for larger projects or production runs due to its economic advantage, whereas TIG is chosen for precision work despite the higher cost.

Best Applications for TIG and MIG Welding Aluminum

TIG welding aluminum is ideal for thin sections and precision applications such as aerospace components, automotive parts, and artistic metalwork due to its superior control and clean welds. MIG welding aluminum excels in thicker materials and high-production environments like shipbuilding, heavy machinery fabrication, and aluminum trailers because of its faster welding speed and higher deposition rate. Selecting between TIG and MIG depends on factors like material thickness, required weld quality, and production efficiency in aluminum manufacturing.

TIG Welding vs MIG Welding (for Aluminum) Infographic

materialdif.com

materialdif.com