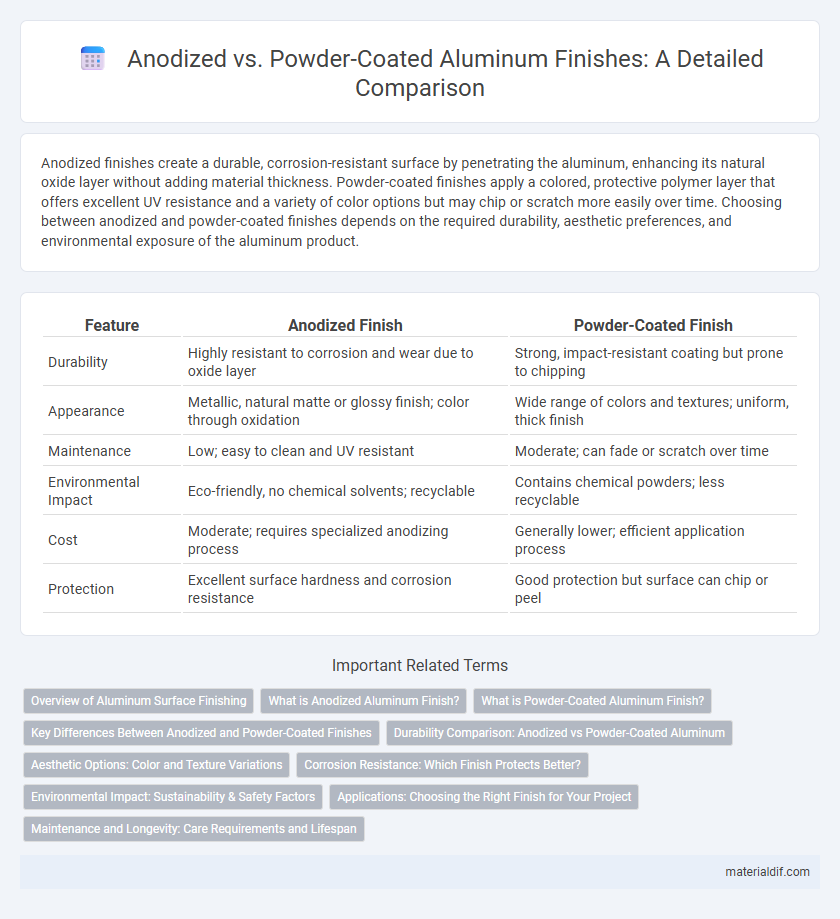

Anodized finishes create a durable, corrosion-resistant surface by penetrating the aluminum, enhancing its natural oxide layer without adding material thickness. Powder-coated finishes apply a colored, protective polymer layer that offers excellent UV resistance and a variety of color options but may chip or scratch more easily over time. Choosing between anodized and powder-coated finishes depends on the required durability, aesthetic preferences, and environmental exposure of the aluminum product.

Table of Comparison

| Feature | Anodized Finish | Powder-Coated Finish |

|---|---|---|

| Durability | Highly resistant to corrosion and wear due to oxide layer | Strong, impact-resistant coating but prone to chipping |

| Appearance | Metallic, natural matte or glossy finish; color through oxidation | Wide range of colors and textures; uniform, thick finish |

| Maintenance | Low; easy to clean and UV resistant | Moderate; can fade or scratch over time |

| Environmental Impact | Eco-friendly, no chemical solvents; recyclable | Contains chemical powders; less recyclable |

| Cost | Moderate; requires specialized anodizing process | Generally lower; efficient application process |

| Protection | Excellent surface hardness and corrosion resistance | Good protection but surface can chip or peel |

Overview of Aluminum Surface Finishing

Aluminum surface finishing enhances durability, corrosion resistance, and aesthetic appeal through processes like anodizing and powder coating. Anodized finish creates a thin, protective oxide layer that is integral to the aluminum, offering superior hardness and corrosion resistance while maintaining a metallic appearance. Powder-coated finish involves applying a durable polymer layer that provides a wider range of colors and textures, with excellent resistance to chipping, fading, and weathering.

What is Anodized Aluminum Finish?

Anodized aluminum finish is an electrochemical process that enhances the natural oxide layer on the aluminum surface, increasing corrosion resistance and durability. This finish creates a porous, protective coating that can be dyed in various colors while maintaining the metal's metallic appearance and texture. Anodizing improves wear resistance and provides a long-lasting, environmentally friendly alternative to organic paints or powder coatings.

What is Powder-Coated Aluminum Finish?

Powder-coated aluminum finish involves applying a dry, powdered paint that is electrostatically charged and sprayed onto the aluminum surface, then cured under heat to form a hard, durable layer. This finish offers superior resistance to chipping, scratching, and fading compared to traditional paint, making it ideal for outdoor applications. The process creates a uniform, smooth coating that enhances corrosion resistance and aesthetic appeal while maintaining environmental friendliness due to low volatile organic compounds (VOCs).

Key Differences Between Anodized and Powder-Coated Finishes

Anodized finishes on aluminum create a protective oxide layer by electrochemical process, enhancing corrosion resistance and wear durability without adding material thickness. Powder-coated finishes apply a colored polymer layer cured under heat, offering greater color variety and thicker protective coverage but can chip or peel over time. Anodizing is typically more scratch-resistant and environmentally friendly, while powder coating provides superior impact resistance and aesthetic flexibility.

Durability Comparison: Anodized vs Powder-Coated Aluminum

Anodized aluminum offers superior corrosion resistance and increased surface hardness due to the electrochemical oxidation process, making it highly durable in harsh environments. Powder-coated aluminum features a thick, protective polymer layer that provides excellent impact resistance and UV stability but may chip or peel over time under heavy mechanical stress. For long-term durability, anodized finishes are preferred in applications requiring abrasion resistance and exposure to extreme weather, while powder coating is ideal for decorative and protective purposes with less abrasive wear.

Aesthetic Options: Color and Texture Variations

Anodized aluminum offers a durable, natural metallic finish with subtle color options such as bronze, black, and champagne, enhancing the metal's grain and texture for a sleek, sophisticated look. Powder-coated aluminum provides a broader spectrum of vibrant colors and uniform matte or glossy textures, allowing for more creative and customizable aesthetic applications. Both finishes improve corrosion resistance, but powder coating delivers greater versatility in color and texture variations tailored to design preferences.

Corrosion Resistance: Which Finish Protects Better?

Anodized aluminum offers superior corrosion resistance by creating a durable, oxide layer that bonds with the metal surface, preventing oxidation and wear in harsh environments. Powder-coated finishes provide a thick, protective polymer layer that resists chipping, fading, and corrosion, but may degrade under prolonged UV exposure or physical damage. In marine or industrial applications, anodizing generally ensures longer-lasting corrosion protection, while powder coating is preferred for aesthetic versatility and impact resistance.

Environmental Impact: Sustainability & Safety Factors

Anodized aluminum finish offers superior environmental benefits due to its non-toxic process that does not produce hazardous waste, and it enhances aluminum's natural corrosion resistance without adding chemicals. Powder-coated finishes involve the use of synthetic resins and curing at high temperatures, which can release volatile organic compounds (VOCs) and generate more waste, though powder coatings are increasingly formulated to minimize environmental harm. Sustainability factors favor anodizing for long-lasting durability and recyclability, while powder coating requires careful disposal of overspray and solvents to ensure safety and environmental compliance.

Applications: Choosing the Right Finish for Your Project

Anodized aluminum provides excellent corrosion resistance and a durable, wear-resistant surface ideal for architectural elements, automotive parts, and electronic housings exposed to harsh environments. Powder-coated aluminum offers a thicker, more vibrant finish suited for outdoor furniture, industrial equipment, and decorative trims requiring superior color variety and impact resistance. Selecting between anodized and powder-coated finishes depends on the specific application demands, environmental exposure, and desired aesthetic longevity.

Maintenance and Longevity: Care Requirements and Lifespan

Anodized aluminum offers superior corrosion resistance and requires minimal maintenance, maintaining its appearance for 20 to 30 years due to its durable oxide layer. Powder-coated aluminum provides a thicker, protective layer that guards against chipping and fading, typically lasting 10 to 15 years but requiring periodic inspections and touch-ups to sustain its finish. Both finishes enhance aluminum's durability, but anodizing demands less upkeep and delivers a longer lifespan in harsh environmental conditions.

Anodized Finish vs Powder-Coated Finish Infographic

materialdif.com

materialdif.com