Alloyed aluminum offers enhanced strength, durability, and corrosion resistance compared to pure aluminum, making it ideal for structural and industrial applications. Pure aluminum, while lightweight and highly malleable, lacks the mechanical robustness needed for heavy-duty use. Choosing alloyed aluminum ensures improved performance in demanding environments without sacrificing the material's inherent lightness.

Table of Comparison

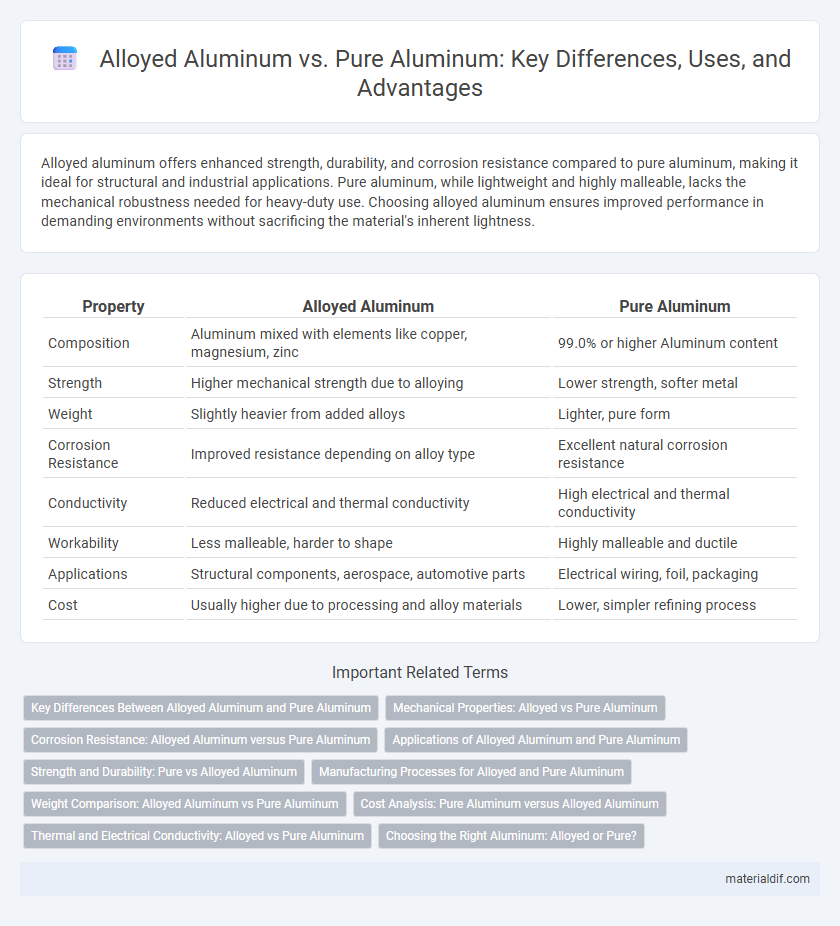

| Property | Alloyed Aluminum | Pure Aluminum |

|---|---|---|

| Composition | Aluminum mixed with elements like copper, magnesium, zinc | 99.0% or higher Aluminum content |

| Strength | Higher mechanical strength due to alloying | Lower strength, softer metal |

| Weight | Slightly heavier from added alloys | Lighter, pure form |

| Corrosion Resistance | Improved resistance depending on alloy type | Excellent natural corrosion resistance |

| Conductivity | Reduced electrical and thermal conductivity | High electrical and thermal conductivity |

| Workability | Less malleable, harder to shape | Highly malleable and ductile |

| Applications | Structural components, aerospace, automotive parts | Electrical wiring, foil, packaging |

| Cost | Usually higher due to processing and alloy materials | Lower, simpler refining process |

Key Differences Between Alloyed Aluminum and Pure Aluminum

Alloyed aluminum contains additional elements like copper, magnesium, or zinc that enhance its strength, durability, and corrosion resistance, making it ideal for structural applications and aerospace components. Pure aluminum, with a minimum of 99% aluminum content, offers superior corrosion resistance and excellent electrical and thermal conductivity but lacks the mechanical strength of alloyed variants. The key differences lie in mechanical properties, corrosion resistance, and suitability for specific industrial uses, with alloyed aluminum preferred for strength-critical applications and pure aluminum favored where conductivity and corrosion resistance are paramount.

Mechanical Properties: Alloyed vs Pure Aluminum

Alloyed aluminum exhibits significantly enhanced mechanical properties compared to pure aluminum, including higher tensile strength, improved hardness, and greater yield strength due to the addition of elements such as copper, magnesium, and silicon. Pure aluminum, while highly ductile and corrosion-resistant, has lower mechanical strength, limiting its use in structural applications where load-bearing capacity is critical. The tailored microstructure of aluminum alloys increases resistance to deformation and improves fatigue strength, making alloyed aluminum preferable for aerospace, automotive, and construction industries.

Corrosion Resistance: Alloyed Aluminum versus Pure Aluminum

Alloyed aluminum typically exhibits enhanced corrosion resistance compared to pure aluminum due to the presence of elements like copper, magnesium, and zinc, which form stable oxide layers that protect the metal surface. Pure aluminum, while naturally forming a protective oxide film, can be more susceptible to pitting and localized corrosion in aggressive environments. The choice between alloyed and pure aluminum depends on the specific application requirements for durability and exposure conditions.

Applications of Alloyed Aluminum and Pure Aluminum

Alloyed aluminum is widely used in aerospace, automotive, and construction industries due to its enhanced strength, corrosion resistance, and machinability, making it ideal for structural components and high-performance parts. Pure aluminum, with its excellent electrical conductivity and corrosion resistance, is primarily utilized in electrical transmission lines, packaging materials, and chemical equipment. The tailored properties of alloyed aluminum enable specialized applications, whereas pure aluminum is preferred where conductivity and formability are critical.

Strength and Durability: Pure vs Alloyed Aluminum

Alloyed aluminum provides significantly higher strength and enhanced durability compared to pure aluminum, due to the addition of elements like copper, magnesium, and zinc that create a stronger microstructure. Pure aluminum, while highly corrosion-resistant and lightweight, lacks the mechanical robustness required for structural applications. Engineers prefer alloyed aluminum for aerospace, automotive, and construction industries where superior strength-to-weight ratio and wear resistance are critical.

Manufacturing Processes for Alloyed and Pure Aluminum

Alloyed aluminum involves the addition of elements such as copper, magnesium, and silicon during melting, which enhances mechanical properties and requires precise control in casting and extrusion processes. Pure aluminum, typically 99.9% aluminum, undergoes simpler manufacturing techniques like rolling and annealing, emphasizing high ductility and corrosion resistance. The selection of manufacturing processes depends on the intended application, with alloyed aluminum demanding advanced heat treatment to optimize strength and durability.

Weight Comparison: Alloyed Aluminum vs Pure Aluminum

Alloyed aluminum typically has a slightly higher density than pure aluminum due to the addition of elements like copper, magnesium, and silicon, which enhance its mechanical properties while increasing weight marginally. Pure aluminum has a density of approximately 2.70 g/cm3, whereas common aluminum alloys range from about 2.75 to 2.85 g/cm3. This small increase in weight is often offset by significant gains in strength and durability, making alloyed aluminum preferable for applications requiring lightweight yet robust materials.

Cost Analysis: Pure Aluminum versus Alloyed Aluminum

Pure aluminum typically incurs lower initial costs due to its simpler refining process and fewer additives, making it more affordable for applications requiring high corrosion resistance and electrical conductivity. Alloyed aluminum, while generally more expensive upfront, offers enhanced mechanical properties such as increased strength, durability, and machinability, which can reduce long-term maintenance and replacement costs in structural and aerospace applications. Cost efficiency depends on balancing pure aluminum's lower material expense against the superior performance and lifespan benefits provided by aluminum alloys in specific industrial uses.

Thermal and Electrical Conductivity: Alloyed vs Pure Aluminum

Pure aluminum exhibits superior thermal and electrical conductivity, typically around 235 W/m*K and 3.5 x 10^7 S/m respectively, due to its minimal impurities and uniform lattice structure. Alloyed aluminum, while offering enhanced mechanical strength and corrosion resistance, experiences reduced conductivity levels because alloying elements disrupt electron flow and heat transfer pathways. Selecting between pure and alloyed aluminum depends on the balance required between conductivity efficiency and structural performance in specific applications.

Choosing the Right Aluminum: Alloyed or Pure?

Choosing the right aluminum depends on application requirements, where alloyed aluminum offers enhanced strength, corrosion resistance, and machinability due to the addition of elements like copper, magnesium, and silicon. Pure aluminum, typically 99.0% to 99.9% pure, excels in electrical conductivity, corrosion resistance, and malleability but lacks the mechanical strength of alloys. For structural or high-stress applications, alloyed aluminum is preferred, while pure aluminum suits electrical and chemical environments needing high conductivity and flexibility.

Alloyed Aluminum vs Pure Aluminum Infographic

materialdif.com

materialdif.com