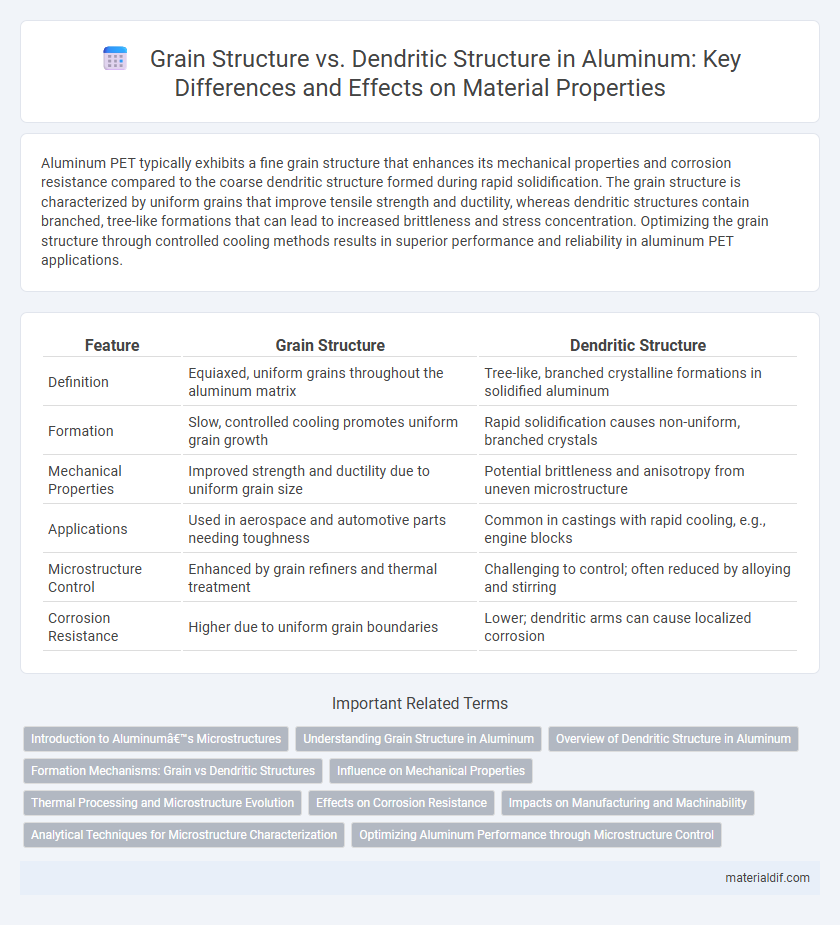

Aluminum PET typically exhibits a fine grain structure that enhances its mechanical properties and corrosion resistance compared to the coarse dendritic structure formed during rapid solidification. The grain structure is characterized by uniform grains that improve tensile strength and ductility, whereas dendritic structures contain branched, tree-like formations that can lead to increased brittleness and stress concentration. Optimizing the grain structure through controlled cooling methods results in superior performance and reliability in aluminum PET applications.

Table of Comparison

| Feature | Grain Structure | Dendritic Structure |

|---|---|---|

| Definition | Equiaxed, uniform grains throughout the aluminum matrix | Tree-like, branched crystalline formations in solidified aluminum |

| Formation | Slow, controlled cooling promotes uniform grain growth | Rapid solidification causes non-uniform, branched crystals |

| Mechanical Properties | Improved strength and ductility due to uniform grain size | Potential brittleness and anisotropy from uneven microstructure |

| Applications | Used in aerospace and automotive parts needing toughness | Common in castings with rapid cooling, e.g., engine blocks |

| Microstructure Control | Enhanced by grain refiners and thermal treatment | Challenging to control; often reduced by alloying and stirring |

| Corrosion Resistance | Higher due to uniform grain boundaries | Lower; dendritic arms can cause localized corrosion |

Introduction to Aluminum’s Microstructures

Aluminum's microstructure plays a crucial role in determining its mechanical and physical properties, with grain structure and dendritic structure being the two primary forms. Grain structure consists of equiaxed grains formed during solidification, providing uniform strength and ductility, while dendritic structure features tree-like formations resulting from non-uniform cooling, often causing anisotropy and variable mechanical behavior. Understanding and controlling these microstructures is essential for optimizing aluminum alloys in automotive, aerospace, and construction applications.

Understanding Grain Structure in Aluminum

Grain structure in aluminum refers to the arrangement of individual crystals or grains within the metal, which significantly influences its mechanical properties and corrosion resistance. Fine, equiaxed grains typically enhance strength and ductility due to more grain boundaries, which hinder dislocation movement. Understanding grain structure is essential for optimizing heat treatment processes and ensuring desired performance in applications such as aerospace and automotive industries.

Overview of Dendritic Structure in Aluminum

Dendritic structure in aluminum refers to the tree-like crystal formations that develop during solidification, significantly influencing mechanical properties and microstructural characteristics. These dendrites grow from nucleation points and create a network of primary arms and secondary branches, affecting grain boundary strength and impurity distribution. Understanding dendritic morphology is crucial for optimizing casting processes and enhancing aluminum alloy performance.

Formation Mechanisms: Grain vs Dendritic Structures

Grain structures in aluminum form during solidification through uniform nucleation and growth, resulting in equiaxed grains that enhance mechanical properties. Dendritic structures develop when solidification occurs under non-equilibrium conditions, characterized by tree-like crystal growth driven by thermal gradients and solute redistribution. Understanding the formation mechanisms of grain versus dendritic structures enables control over microstructure to optimize aluminum's strength, ductility, and corrosion resistance.

Influence on Mechanical Properties

Grain structure in aluminum, characterized by equiaxed grains, enhances mechanical properties such as tensile strength and ductility by providing uniform stress distribution and resistance to crack propagation. Dendritic structures, formed during rapid solidification, often result in anisotropic properties and the presence of microsegregation, which can reduce toughness and increase susceptibility to corrosion. Optimizing cooling rates and alloy composition controls the transition between grain and dendritic structures, directly influencing aluminum's performance in aerospace and automotive applications.

Thermal Processing and Microstructure Evolution

Thermal processing of aluminum significantly influences its grain structure and dendritic formation, impacting mechanical properties and corrosion resistance. Controlled cooling rates during solidification promote refined grain structures, while faster cooling favors dendritic microstructures characterized by primary and secondary arms. Optimizing thermal parameters enables precise microstructure evolution, enhancing strength and ductility in aluminum alloys.

Effects on Corrosion Resistance

Grain structure in aluminum typically offers improved corrosion resistance due to the uniform distribution of grains that minimize localized anodic and cathodic sites, reducing susceptibility to intergranular corrosion. Conversely, dendritic structures often exhibit segregation of alloying elements along the dendrite arms, creating micro-galvanic cells that accelerate corrosion processes. Optimizing grain refinement techniques enhances aluminum's protective oxide layer stability, thereby extending its lifespan in corrosive environments.

Impacts on Manufacturing and Machinability

Grain structure in aluminum enhances uniform mechanical properties and improves machinability by providing consistent hardness and strength throughout the material. In contrast, dendritic structures, formed during rapid solidification, can create micro-segregation and non-uniform mechanical properties, leading to challenges in manufacturing processes such as casting and machining. Optimizing aluminum alloys for a refined grain structure reduces tool wear, improves surface finish, and ensures dimensional stability in precision manufacturing applications.

Analytical Techniques for Microstructure Characterization

Analytical techniques for microstructure characterization in aluminum focus on revealing grain structure and dendritic structure differences using optical microscopy and scanning electron microscopy (SEM) for high-resolution imaging. Electron backscatter diffraction (EBSD) provides detailed crystallographic orientation maps essential for grain boundary analysis, distinguishing between equiaxed grains and dendritic arms. Energy-dispersive X-ray spectroscopy (EDS) complements these methods by identifying compositional variations within dendritic structures, facilitating a comprehensive understanding of solidification patterns.

Optimizing Aluminum Performance through Microstructure Control

Optimizing aluminum performance requires precise control over grain structure and dendritic structure, as fine, equiaxed grains enhance mechanical strength and corrosion resistance while reducing anisotropy. Controlling solidification parameters promotes uniform grain refinement, minimizing dendritic formation that can cause segregation and weaken alloy integrity. Advanced microstructure control techniques such as grain refiners and directional solidification are essential for maximizing aluminum's structural and functional properties.

Grain Structure vs Dendritic Structure Infographic

materialdif.com

materialdif.com