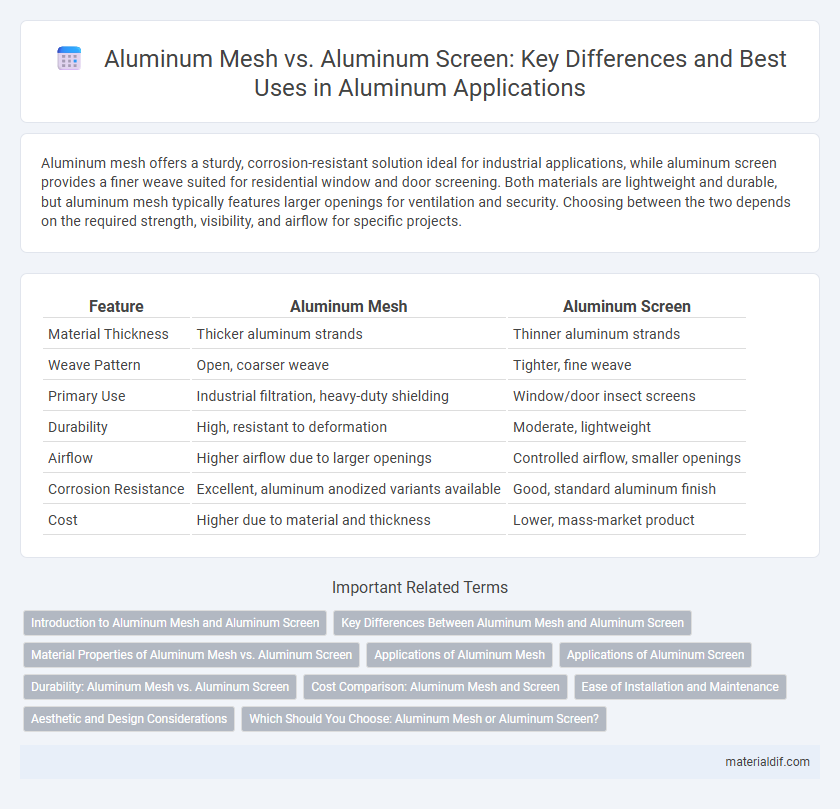

Aluminum mesh offers a sturdy, corrosion-resistant solution ideal for industrial applications, while aluminum screen provides a finer weave suited for residential window and door screening. Both materials are lightweight and durable, but aluminum mesh typically features larger openings for ventilation and security. Choosing between the two depends on the required strength, visibility, and airflow for specific projects.

Table of Comparison

| Feature | Aluminum Mesh | Aluminum Screen |

|---|---|---|

| Material Thickness | Thicker aluminum strands | Thinner aluminum strands |

| Weave Pattern | Open, coarser weave | Tighter, fine weave |

| Primary Use | Industrial filtration, heavy-duty shielding | Window/door insect screens |

| Durability | High, resistant to deformation | Moderate, lightweight |

| Airflow | Higher airflow due to larger openings | Controlled airflow, smaller openings |

| Corrosion Resistance | Excellent, aluminum anodized variants available | Good, standard aluminum finish |

| Cost | Higher due to material and thickness | Lower, mass-market product |

Introduction to Aluminum Mesh and Aluminum Screen

Aluminum mesh consists of woven or welded strands of aluminum wire forming a durable grid, primarily used for filtration, security, and ventilation purposes. Aluminum screens feature tightly spaced aluminum wires designed to provide insect protection while allowing airflow and visibility in residential and commercial windows. Both products leverage aluminum's corrosion resistance, lightweight properties, and strength, but differ in mesh size and functional applications.

Key Differences Between Aluminum Mesh and Aluminum Screen

Aluminum mesh consists of larger, more open weaves designed for structural support and ventilation, while aluminum screens feature finer, tighter weaves primarily intended for insect protection and filtration. The mesh offers greater durability and resistance to weather, making it ideal for industrial applications, whereas screens prioritize visibility and airflow control in residential settings. Material thickness and weave pattern are critical factors distinguishing aluminum mesh's robustness from the screen's delicate filtering capabilities.

Material Properties of Aluminum Mesh vs. Aluminum Screen

Aluminum mesh and aluminum screen both utilize high-purity aluminum, but their structural designs impact material properties differently. Aluminum mesh features a woven pattern that provides greater flexibility and tensile strength, enhancing durability in applications requiring pliability. In contrast, aluminum screens have a finer, tighter weave that offers superior corrosion resistance and improved particle filtration due to reduced pore size.

Applications of Aluminum Mesh

Aluminum mesh is widely used in applications requiring lightweight, corrosion-resistant materials such as filtration systems, insect screens, and protective covers in industrial environments. Its high durability and flexibility make it ideal for architectural facades, ventilation grilles, and security fencing. Aluminum screen, while similar, is primarily designed for insect control in residential and commercial windows rather than heavy-duty industrial use.

Applications of Aluminum Screen

Aluminum screen is widely used in window and door screening applications due to its lightweight durability and resistance to corrosion, which makes it ideal for outdoor environments. It provides effective insect protection while allowing air and light to pass through, enhancing ventilation without compromising security. Commonly employed in residential, commercial, and industrial settings, aluminum screen supports energy efficiency and weather resistance in all climates.

Durability: Aluminum Mesh vs. Aluminum Screen

Aluminum mesh and aluminum screen differ significantly in durability, with aluminum mesh offering superior resistance to corrosion, dents, and weathering due to its thicker gauge and tighter weave. The aluminum screen, often thinner and more flexible, is more prone to damage from impacts and prolonged exposure to harsh environmental conditions. For applications requiring long-lasting protection and structural integrity, aluminum mesh provides enhanced durability compared to standard aluminum screens.

Cost Comparison: Aluminum Mesh and Screen

Aluminum mesh generally costs less than aluminum screen due to its simpler manufacturing process and lower material density. The price difference is also influenced by the mesh size and thickness, with finer screens requiring more aluminum and precision, thus increasing the cost. For budget-sensitive projects, aluminum mesh offers an economical solution, whereas aluminum screens provide enhanced durability at a higher price point.

Ease of Installation and Maintenance

Aluminum mesh is lightweight and flexible, making it easier to cut and fit into various frame sizes during installation, while aluminum screens are more rigid and may require precise measurements and tools for proper fitting. Maintenance of aluminum mesh involves simple cleaning with water and mild detergent due to its corrosion-resistant properties, whereas aluminum screens might trap more dirt in their tighter weave, necessitating more frequent cleaning. Both materials resist rust, but aluminum mesh's design often allows quicker drying and less buildup, reducing long-term upkeep efforts.

Aesthetic and Design Considerations

Aluminum mesh offers a sleek and modern aesthetic with its uniform pattern and lightweight structure, making it ideal for contemporary architectural designs. In contrast, aluminum screens typically provide a more robust and textured appearance, enhancing privacy while maintaining an industrial or rustic style. Both options allow for customizable finishes and colors, enabling designers to tailor the visual impact to specific project requirements.

Which Should You Choose: Aluminum Mesh or Aluminum Screen?

Aluminum mesh offers a coarser weave with larger openings, making it ideal for applications that require durability and ventilation, such as fencing or industrial filtration. Aluminum screen features a finer weave providing better insect protection and is commonly used in window and door screens for residential purposes. Selecting between aluminum mesh and aluminum screen depends on whether the priority is robust airflow and strength or effective pest control and fine filtration.

Aluminum Mesh vs Aluminum Screen Infographic

materialdif.com

materialdif.com