Forged aluminum offers superior strength and durability due to its dense, grain-aligned structure, making it ideal for high-performance applications. Cast aluminum provides more complex shapes and cost-effective production but has lower tensile strength and is more prone to porosity. Choosing between forged and cast aluminum depends on the balance needed between mechanical strength and manufacturing flexibility.

Table of Comparison

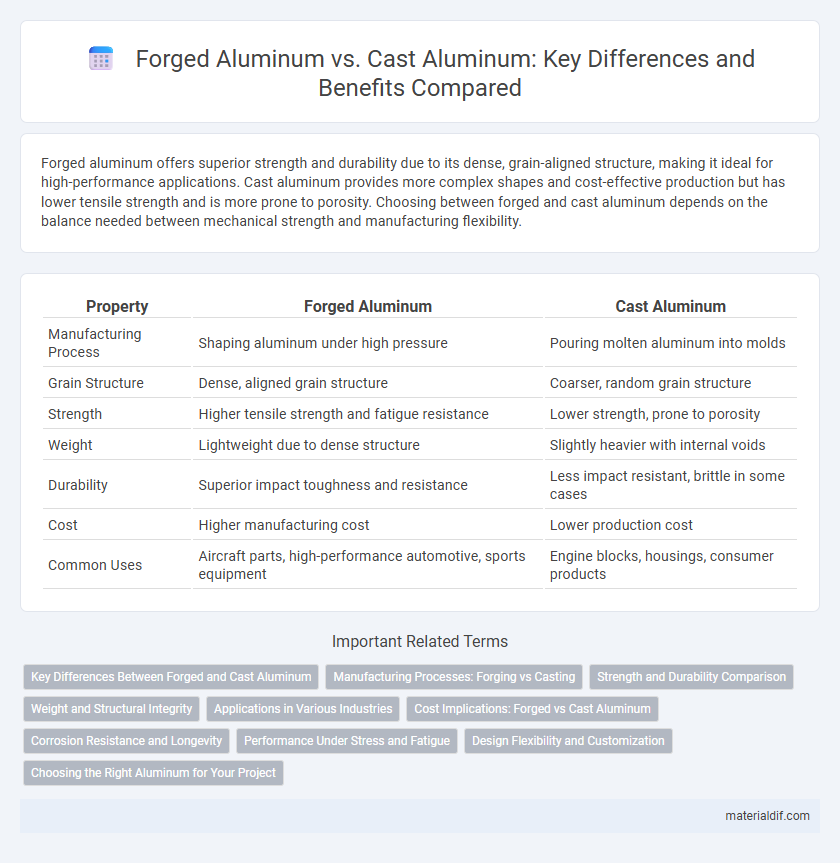

| Property | Forged Aluminum | Cast Aluminum |

|---|---|---|

| Manufacturing Process | Shaping aluminum under high pressure | Pouring molten aluminum into molds |

| Grain Structure | Dense, aligned grain structure | Coarser, random grain structure |

| Strength | Higher tensile strength and fatigue resistance | Lower strength, prone to porosity |

| Weight | Lightweight due to dense structure | Slightly heavier with internal voids |

| Durability | Superior impact toughness and resistance | Less impact resistant, brittle in some cases |

| Cost | Higher manufacturing cost | Lower production cost |

| Common Uses | Aircraft parts, high-performance automotive, sports equipment | Engine blocks, housings, consumer products |

Key Differences Between Forged and Cast Aluminum

Forged aluminum is produced by shaping solid aluminum under high pressure, resulting in a denser and stronger material with superior mechanical properties compared to cast aluminum, which is formed by pouring molten aluminum into molds. The forging process minimizes porosity and improves grain structure, enhancing fatigue resistance and impact strength, making it ideal for high-stress applications such as aerospace and automotive parts. Cast aluminum offers more complex shapes and lower production costs but generally exhibits lower tensile strength and toughness due to its coarser microstructure and potential for internal defects.

Manufacturing Processes: Forging vs Casting

Forged aluminum undergoes a manufacturing process where aluminum billets are heated and shaped under high pressure, resulting in a dense, uniform grain structure that enhances strength and fatigue resistance. Cast aluminum is produced by pouring molten aluminum into molds, allowing complex shapes and intricate designs but often resulting in a coarser grain structure with potential porosity that can affect mechanical properties. The forging process emphasizes mechanical performance through grain flow alignment, while casting offers design flexibility at the cost of slightly reduced structural integrity.

Strength and Durability Comparison

Forged aluminum exhibits superior strength and durability compared to cast aluminum due to its denser grain structure formed under high pressure, which reduces the likelihood of internal defects and improves impact resistance. Cast aluminum, while more cost-effective and suitable for complex shapes, tends to have a coarser grain and higher porosity, making it less resistant to fatigue and mechanical stress. In applications requiring high performance and longevity, such as aerospace and automotive components, forged aluminum is preferred for its enhanced tensile strength and toughness.

Weight and Structural Integrity

Forged aluminum exhibits superior structural integrity compared to cast aluminum due to its denser, more uniform grain structure formed under high pressure, resulting in enhanced strength and durability. Cast aluminum, while generally heavier and less robust, allows for more complex shapes but contains internal porosity that can compromise weight efficiency and mechanical performance. The weight advantage of forged aluminum is critical in applications like aerospace and automotive manufacturing, where reducing mass without sacrificing strength improves fuel efficiency and overall safety.

Applications in Various Industries

Forged aluminum offers superior strength and durability, making it ideal for aerospace and automotive components that require high performance under stress. Cast aluminum is favored in manufacturing complex shapes with precise dimensions, commonly used in engine blocks, housings, and decorative parts across the automotive, construction, and consumer goods industries. Both materials fulfill specific needs, with forged aluminum excelling in structural applications and cast aluminum preferred for detailed, intricate designs.

Cost Implications: Forged vs Cast Aluminum

Forged aluminum typically incurs higher manufacturing costs due to its more labor-intensive process, involving high pressure and precise shaping to enhance material strength and durability. Cast aluminum offers a cost-effective alternative with lower production expenses by pouring molten metal into molds, making it suitable for complex shapes and large-scale production. Businesses must weigh the initial cost savings of cast aluminum against the long-term benefits of forged aluminum's superior mechanical properties and reduced failure rates.

Corrosion Resistance and Longevity

Forged aluminum exhibits superior corrosion resistance compared to cast aluminum due to its denser microstructure, which reduces porosity and minimizes exposure to corrosive elements. This enhanced durability contributes to the longer lifespan of forged aluminum components, making them ideal for applications requiring high mechanical strength and environmental resilience. Cast aluminum, while cost-effective, tends to have higher porosity and impurity levels, leading to increased susceptibility to corrosion and shorter service life in harsh environments.

Performance Under Stress and Fatigue

Forged aluminum exhibits superior performance under stress and fatigue due to its dense, uniform grain structure formed through high-pressure deformation, enhancing strength and resistance to crack propagation. Cast aluminum, while cost-effective and capable of complex shapes, contains inherent porosity and microstructural inconsistencies that reduce its fatigue life and stress endurance. For applications demanding high durability and longevity under cyclic loading, forged aluminum offers a distinct advantage over cast aluminum.

Design Flexibility and Customization

Forged aluminum offers superior design flexibility and customization due to its ability to achieve complex shapes and intricate details with enhanced strength and durability. Cast aluminum, while more cost-effective for large production runs, is limited by mold constraints, resulting in less intricate designs and reduced structural integrity. Choosing forged aluminum enables tailored, high-performance components ideal for demanding applications requiring precise customization.

Choosing the Right Aluminum for Your Project

Forged aluminum offers superior strength and durability due to its refined grain structure, making it ideal for high-stress applications like aerospace and automotive components. Cast aluminum provides more complex shapes with excellent corrosion resistance, suitable for architectural and decorative projects. Selecting the right aluminum depends on project requirements for strength, precision, and design complexity.

Forged Aluminum vs Cast Aluminum Infographic

materialdif.com

materialdif.com