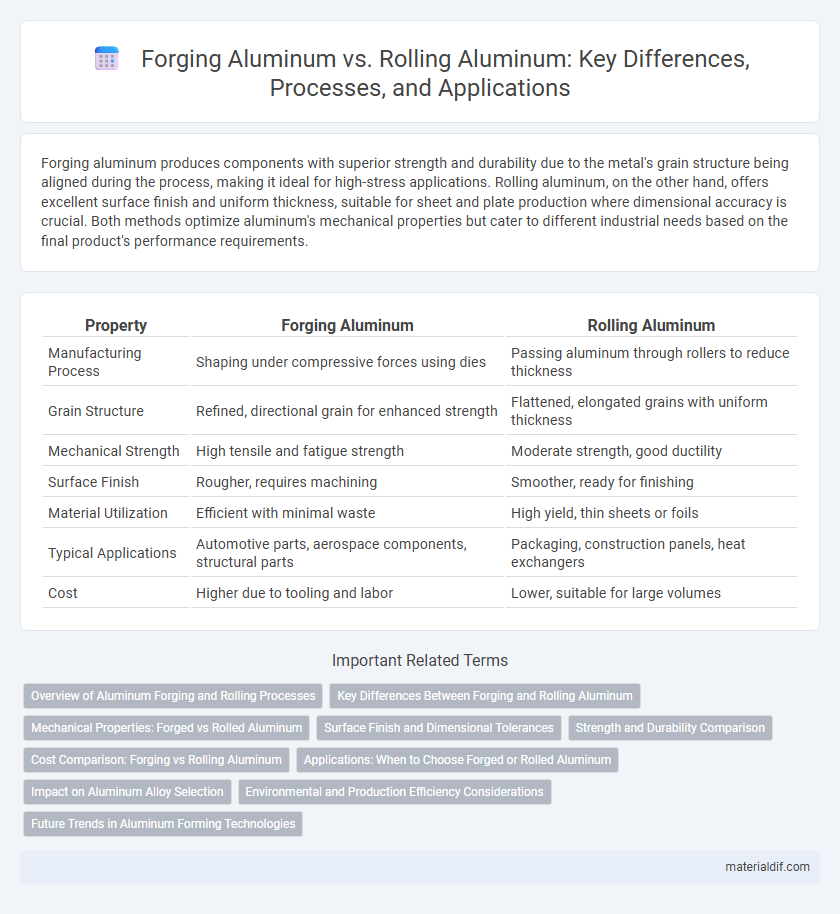

Forging aluminum produces components with superior strength and durability due to the metal's grain structure being aligned during the process, making it ideal for high-stress applications. Rolling aluminum, on the other hand, offers excellent surface finish and uniform thickness, suitable for sheet and plate production where dimensional accuracy is crucial. Both methods optimize aluminum's mechanical properties but cater to different industrial needs based on the final product's performance requirements.

Table of Comparison

| Property | Forging Aluminum | Rolling Aluminum |

|---|---|---|

| Manufacturing Process | Shaping under compressive forces using dies | Passing aluminum through rollers to reduce thickness |

| Grain Structure | Refined, directional grain for enhanced strength | Flattened, elongated grains with uniform thickness |

| Mechanical Strength | High tensile and fatigue strength | Moderate strength, good ductility |

| Surface Finish | Rougher, requires machining | Smoother, ready for finishing |

| Material Utilization | Efficient with minimal waste | High yield, thin sheets or foils |

| Typical Applications | Automotive parts, aerospace components, structural parts | Packaging, construction panels, heat exchangers |

| Cost | Higher due to tooling and labor | Lower, suitable for large volumes |

Overview of Aluminum Forging and Rolling Processes

Aluminum forging involves shaping metal by applying compressive forces using a hammer or press, resulting in enhanced mechanical properties such as increased strength and improved grain structure. Rolling aluminum, on the other hand, passes the metal through a series of rollers to reduce thickness and create uniform sheet or plate forms, optimizing surface finish and dimensional tolerances. Both processes are essential in manufacturing, with forging ideal for high-strength components and rolling suited for producing large, consistent aluminum sheets.

Key Differences Between Forging and Rolling Aluminum

Forging aluminum involves shaping the metal using compressive forces, which enhances its strength and structural integrity by aligning the grain flow, while rolling aluminum involves passing the metal through rollers to reduce thickness and improve surface finish with greater dimensional accuracy. Forged aluminum typically exhibits higher tensile strength and better fatigue resistance, making it ideal for aerospace and automotive components, whereas rolled aluminum offers superior flatness and is commonly used in sheet products and foil applications. The key differences lie in their grain structure, mechanical properties, and typical use cases, with forging preferred for critical load-bearing parts and rolling favored for large-scale sheet manufacturing.

Mechanical Properties: Forged vs Rolled Aluminum

Forged aluminum exhibits superior mechanical properties, such as enhanced tensile strength and fatigue resistance, due to its refined grain structure resulting from compressive forces during forging. Rolled aluminum, while offering consistent thickness and superior surface finish, generally has lower strength compared to forged aluminum because the rolling process elongates grains and may introduce directional properties. The choice between forging and rolling aluminum depends on the specific mechanical performance requirements, with forging preferred for high-stress applications demanding maximum durability.

Surface Finish and Dimensional Tolerances

Forging aluminum produces a denser and more uniform surface finish with superior structural integrity compared to rolling, which often results in surface lines and less uniformity. Forged aluminum components exhibit tighter dimensional tolerances, typically within +-0.01 to +-0.05 mm, due to controlled deformation processes, whereas rolled aluminum sheets generally have broader tolerances around +-0.1 to +-0.2 mm. These differences make forging preferable for high-precision applications requiring enhanced mechanical properties and surface quality.

Strength and Durability Comparison

Forging aluminum enhances strength and durability by creating a refined grain structure that improves resistance to fatigue and impact compared to rolling aluminum, which can introduce anisotropy due to directional grain flow. Forged aluminum components typically exhibit superior mechanical properties and higher tensile strength, making them ideal for high-stress applications. Rolling aluminum offers better surface finish and dimensional accuracy but often results in lower toughness and increased susceptibility to cracking under extreme stress.

Cost Comparison: Forging vs Rolling Aluminum

Forging aluminum typically incurs higher costs due to the intensive labor, specialized equipment, and longer cycle times required to shape the metal under extreme pressure. Rolling aluminum offers a more cost-effective solution by enabling continuous production with lower energy consumption and less material waste, making it ideal for large-scale manufacturing. While forging provides superior mechanical properties for critical applications, rolling aluminum remains the preferred method where cost efficiency and high-volume output are priorities.

Applications: When to Choose Forged or Rolled Aluminum

Forged aluminum offers superior strength and fatigue resistance, making it ideal for aerospace components, high-performance automotive parts, and structural applications requiring high durability. Rolled aluminum excels in producing uniform thickness sheets and plates, preferred for packaging, automotive body panels, and construction materials where consistent surface finish and precise dimensions are critical. Selecting forged or rolled aluminum depends on the specific mechanical properties and form factors required by the end-use application.

Impact on Aluminum Alloy Selection

Forging aluminum produces denser and stronger components by refining the grain structure, making it ideal for high-strength aluminum alloys such as 7075 and 2024 commonly used in aerospace applications. Rolling aluminum primarily yields sheets and plates with uniform thickness, favoring alloys like 6061 and 3003 that exhibit excellent formability and corrosion resistance. The choice between forging and rolling directly influences aluminum alloy selection based on mechanical property requirements and manufacturing constraints.

Environmental and Production Efficiency Considerations

Forging aluminum typically consumes more energy than rolling due to the intense heat and pressure required, impacting overall production efficiency and carbon emissions. Rolling aluminum enables continuous processing with less energy use and material waste, enhancing environmental sustainability. Both methods demand careful resource management, but rolling offers greater scalability with lower ecological footprint in large-scale manufacturing.

Future Trends in Aluminum Forming Technologies

Forging aluminum enhances mechanical properties through refined grain structures, while rolling aluminum excels in producing thin, uniform sheets with high dimensional accuracy. Future trends in aluminum forming technologies emphasize hybrid processes combining forging and rolling to achieve superior strength-to-weight ratios and improved surface finishes. Advanced innovations such as additive manufacturing integration and AI-driven process optimization are poised to revolutionize aluminum component production, boosting efficiency and sustainability in aerospace and automotive industries.

Forging Aluminum vs Rolling Aluminum Infographic

materialdif.com

materialdif.com