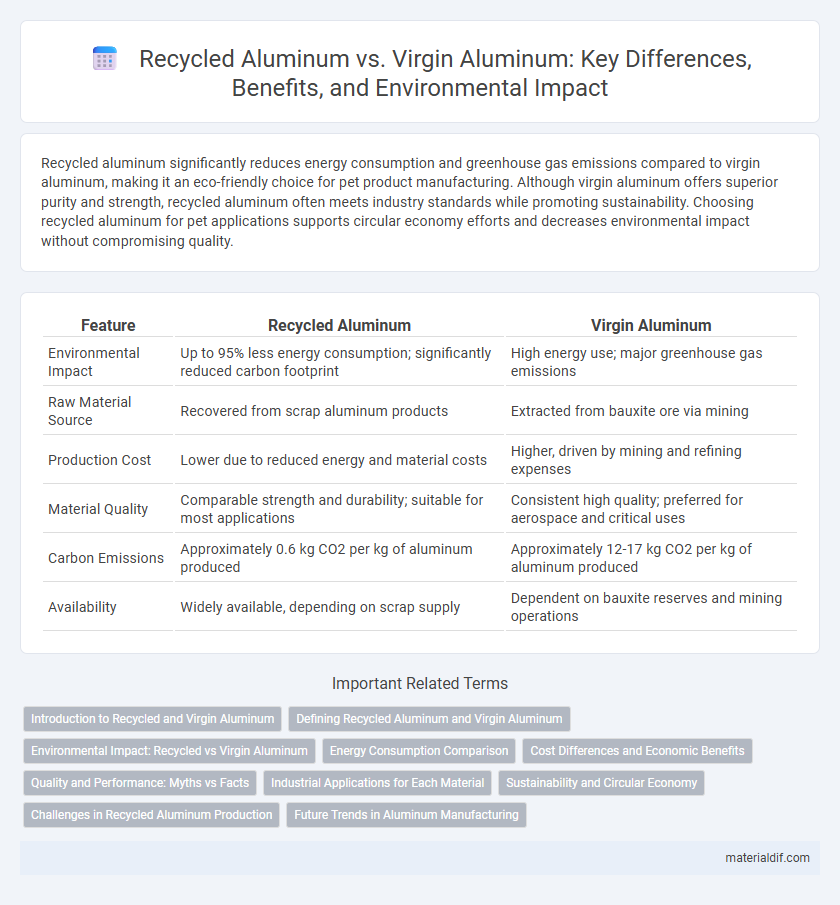

Recycled aluminum significantly reduces energy consumption and greenhouse gas emissions compared to virgin aluminum, making it an eco-friendly choice for pet product manufacturing. Although virgin aluminum offers superior purity and strength, recycled aluminum often meets industry standards while promoting sustainability. Choosing recycled aluminum for pet applications supports circular economy efforts and decreases environmental impact without compromising quality.

Table of Comparison

| Feature | Recycled Aluminum | Virgin Aluminum |

|---|---|---|

| Environmental Impact | Up to 95% less energy consumption; significantly reduced carbon footprint | High energy use; major greenhouse gas emissions |

| Raw Material Source | Recovered from scrap aluminum products | Extracted from bauxite ore via mining |

| Production Cost | Lower due to reduced energy and material costs | Higher, driven by mining and refining expenses |

| Material Quality | Comparable strength and durability; suitable for most applications | Consistent high quality; preferred for aerospace and critical uses |

| Carbon Emissions | Approximately 0.6 kg CO2 per kg of aluminum produced | Approximately 12-17 kg CO2 per kg of aluminum produced |

| Availability | Widely available, depending on scrap supply | Dependent on bauxite reserves and mining operations |

Introduction to Recycled and Virgin Aluminum

Recycled aluminum is produced by melting down scrap aluminum, significantly reducing energy consumption by up to 95% compared to virgin aluminum, which is extracted from bauxite ore through energy-intensive processes like refining and smelting. Virgin aluminum offers high purity and strength, making it ideal for applications requiring specific mechanical properties, while recycled aluminum provides a cost-effective and eco-friendly alternative with slightly varied material characteristics. The shift towards recycled aluminum supports sustainability by conserving natural resources and lowering greenhouse gas emissions associated with primary aluminum production.

Defining Recycled Aluminum and Virgin Aluminum

Recycled aluminum is produced by melting down used aluminum scrap, significantly reducing energy consumption compared to processing virgin aluminum, which is extracted from bauxite ore through refining and smelting. Virgin aluminum offers high purity and consistent quality, essential for applications requiring stringent material properties, whereas recycled aluminum supports sustainability by lowering carbon emissions and conserving natural resources. Both forms of aluminum play crucial roles in manufacturing, with recycled aluminum contributing to circular economy initiatives and virgin aluminum providing the raw material for new, high-performance aluminum products.

Environmental Impact: Recycled vs Virgin Aluminum

Recycled aluminum significantly reduces environmental impact by using up to 95% less energy compared to virgin aluminum production, which involves energy-intensive bauxite mining and refining. The recycling process lowers greenhouse gas emissions and conserves natural resources while minimizing landfill waste. Utilizing recycled aluminum supports circular economy principles, decreasing overall carbon footprint and preserving ecosystems.

Energy Consumption Comparison

Recycled aluminum uses up to 95% less energy than virgin aluminum production, significantly reducing carbon emissions and environmental impact. Producing one ton of recycled aluminum consumes approximately 5% of the energy required for extracting and processing raw bauxite ore into virgin aluminum. This energy efficiency makes recycled aluminum a highly sustainable alternative in manufacturing and construction industries.

Cost Differences and Economic Benefits

Recycled aluminum requires only 5% of the energy needed to produce virgin aluminum, resulting in significantly lower production costs and reduced greenhouse gas emissions. The cost savings from using recycled aluminum can translate into competitive pricing and higher profit margins for manufacturers. Economic benefits include decreased reliance on raw bauxite mining, lowering environmental remediation expenses, and supporting sustainable supply chains.

Quality and Performance: Myths vs Facts

Recycled aluminum maintains nearly identical quality and performance levels as virgin aluminum due to its closed-loop recycling process, which preserves its structural integrity and purity. Myths about inferior strength or durability in recycled aluminum are debunked by extensive metallurgical testing showing consistent alloy composition and mechanical properties. Industrial standards confirm that recycled aluminum alloys meet or exceed performance requirements in applications ranging from aerospace to automotive manufacturing.

Industrial Applications for Each Material

Recycled aluminum is widely favored in industrial applications due to its significantly lower energy consumption--up to 95% less than virgin aluminum--making it ideal for manufacturing automotive parts, packaging, and construction materials. Virgin aluminum is preferred in aerospace and high-performance sectors where material purity, strength, and consistency are critical for meeting stringent safety standards. Both materials play crucial roles in industrial manufacturing, with recycled aluminum supporting sustainability goals and virgin aluminum enabling advanced engineering requirements.

Sustainability and Circular Economy

Recycled aluminum significantly reduces energy consumption by up to 95% compared to virgin aluminum production, making it a cornerstone of sustainable manufacturing. Utilizing recycled aluminum supports a circular economy by minimizing raw material extraction and decreasing greenhouse gas emissions. This closed-loop process extends aluminum's lifecycle, promoting resource efficiency and environmental conservation.

Challenges in Recycled Aluminum Production

Recycled aluminum production faces challenges such as contamination from coatings, paints, and other metals that reduce material purity and affect the mechanical properties of the final product. Energy consumption in recycling processes, although significantly lower than virgin aluminum production, still requires optimization to minimize environmental impact and cost. Furthermore, inconsistencies in scrap supply and quality create difficulties in maintaining steady production and meeting industry standards for recycled aluminum.

Future Trends in Aluminum Manufacturing

Recycled aluminum significantly reduces energy consumption by up to 95% compared to virgin aluminum, making it a critical focus for future sustainable manufacturing trends. Advanced sorting and melting technologies are being developed to improve the quality and yield of recycled aluminum, facilitating a circular economy in the metal industry. Innovations in alloy formulation and processing techniques aim to enhance the performance of recycled aluminum, driving increased adoption in automotive, aerospace, and construction sectors.

Recycled Aluminum vs Virgin Aluminum Infographic

materialdif.com

materialdif.com