Aluminum laminate offers enhanced flexibility and barrier properties by combining multiple layers, making it ideal for packaging sensitive products. In contrast, aluminum monoblock consists of a single, solid aluminum layer, providing superior durability and resistance to punctures. Choosing between aluminum laminate and monoblock depends on the specific requirements for protection, weight, and cost efficiency in pet packaging applications.

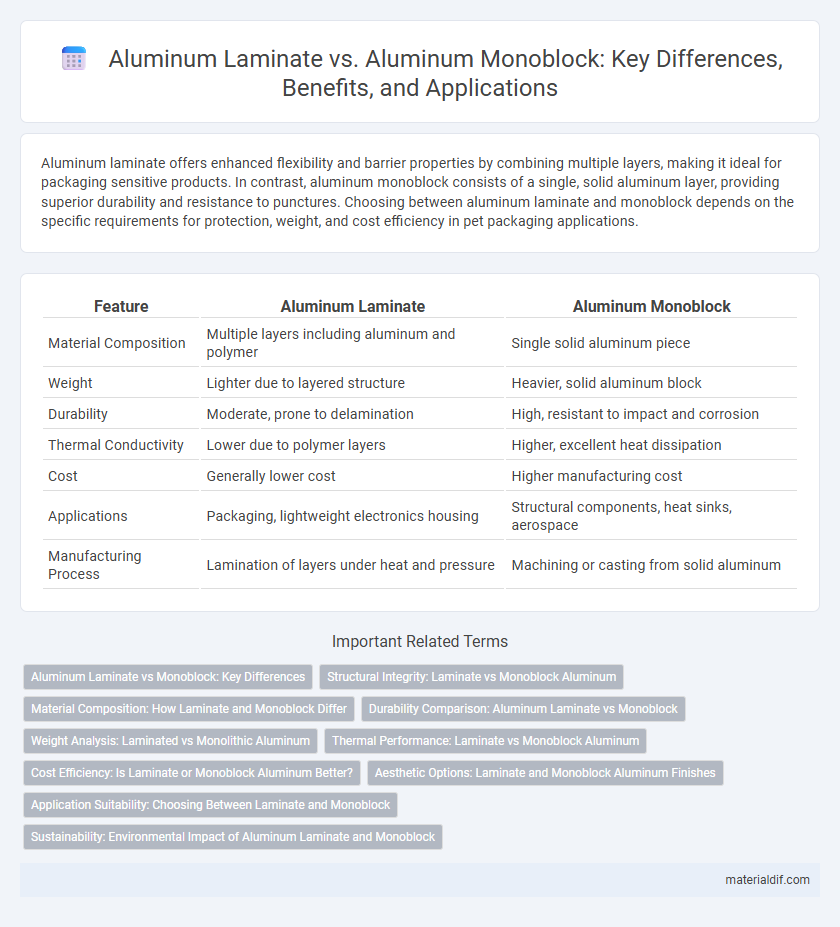

Table of Comparison

| Feature | Aluminum Laminate | Aluminum Monoblock |

|---|---|---|

| Material Composition | Multiple layers including aluminum and polymer | Single solid aluminum piece |

| Weight | Lighter due to layered structure | Heavier, solid aluminum block |

| Durability | Moderate, prone to delamination | High, resistant to impact and corrosion |

| Thermal Conductivity | Lower due to polymer layers | Higher, excellent heat dissipation |

| Cost | Generally lower cost | Higher manufacturing cost |

| Applications | Packaging, lightweight electronics housing | Structural components, heat sinks, aerospace |

| Manufacturing Process | Lamination of layers under heat and pressure | Machining or casting from solid aluminum |

Aluminum Laminate vs Monoblock: Key Differences

Aluminum laminate consists of layered aluminum sheets bonded together with polymers, offering enhanced flexibility and improved thermal insulation properties compared to aluminum monoblock, which is a solid, single-piece aluminum structure known for superior mechanical strength and durability. The laminate design enables better resistance to corrosion and noise reduction, while monoblock aluminum excels in applications requiring high structural integrity and uniform heat distribution. Key differences include weight, with laminate being lighter and more versatile for architectural applications, whereas monoblock provides higher load-bearing capacity and longevity.

Structural Integrity: Laminate vs Monoblock Aluminum

Aluminum monoblock offers superior structural integrity due to its single-piece construction, eliminating weak points associated with joints or adhesives found in aluminum laminate. The monoblock's homogeneous material distribution enhances strength, durability, and resistance to mechanical stress. Conversely, aluminum laminate, while lighter and more flexible, may face delamination risks and reduced load-bearing capacity under high stress.

Material Composition: How Laminate and Monoblock Differ

Aluminum laminate consists of multiple layers, typically aluminum sheets bonded with polymer or other materials, enhancing flexibility, insulation, and corrosion resistance. In contrast, aluminum monoblock is a single, solid piece of aluminum, offering superior structural integrity and durability but less adaptability in terms of design and thermal properties. The differing material compositions directly impact their applications in construction, packaging, and automotive industries.

Durability Comparison: Aluminum Laminate vs Monoblock

Aluminum monoblock offers superior durability compared to aluminum laminate due to its solid, single-piece construction, which resists deformation and corrosion more effectively. Aluminum laminate, consisting of layered materials, may be prone to delamination and damage under extreme stress or prolonged exposure to harsh environments. The enhanced structural integrity of monoblock aluminum makes it ideal for applications demanding long-lasting performance and minimal maintenance.

Weight Analysis: Laminated vs Monolithic Aluminum

Aluminum laminate consists of multiple bonded layers, resulting in a lighter composite with high strength-to-weight ratio compared to monolithic aluminum, which is a solid, single-piece material. Weight analysis reveals aluminum laminate often reduces overall structural weight by up to 30% while maintaining comparable mechanical properties, enhancing fuel efficiency and load capacity in aerospace and automotive applications. Monolithic aluminum, though heavier, provides excellent uniformity and durability, often preferred where maximum impact resistance and fabrication simplicity are crucial.

Thermal Performance: Laminate vs Monoblock Aluminum

Aluminum laminate windows combine multiple aluminum layers with insulating materials, significantly reducing thermal conductivity and enhancing energy efficiency compared to monoblock aluminum, which consists of a single solid aluminum profile prone to higher heat transfer. The thermal break technology within laminate structures minimizes heat loss and condensation, making laminate aluminum ideal for climates demanding superior insulation performance. Monoblock aluminum's uniform metal composition lacks insulation barriers, resulting in less effective thermal performance and increased energy consumption.

Cost Efficiency: Is Laminate or Monoblock Aluminum Better?

Aluminum laminate offers superior cost efficiency due to its lower material and fabrication expenses compared to aluminum monoblock, which requires more intensive processing and higher raw material quality. Laminate panels combine a thin aluminum surface with cost-effective core materials, reducing overall production costs while maintaining adequate durability for many applications. Monoblock aluminum, although more expensive, provides enhanced strength and longevity, making it a cost-effective choice only in highly demanding environments where these properties justify the investment.

Aesthetic Options: Laminate and Monoblock Aluminum Finishes

Aluminum laminate offers a wide range of decorative finishes, including wood grains, metallic sheens, and vibrant colors, providing diverse design flexibility for modern architectural applications. Monoblock aluminum features a uniform, sleek surface with anodized or powder-coated finishes that emphasize durability and a minimalist aesthetic. Both finishes enhance corrosion resistance, but laminate excels in customizable textures while monoblock prioritizes structural integrity and a consistent appearance.

Application Suitability: Choosing Between Laminate and Monoblock

Aluminum laminate suits applications requiring enhanced corrosion resistance and flexibility, ideal for packaging, roofing, and cladding. Aluminum monoblock, with its solid and robust structure, excels in structural and industrial uses, such as automotive parts and heavy machinery components. Selecting between laminate and monoblock depends on specific application needs like durability, weight, and resistance to environmental factors.

Sustainability: Environmental Impact of Aluminum Laminate and Monoblock

Aluminum laminate and aluminum monoblock differ significantly in their environmental impact, with aluminum monoblock offering higher sustainability due to its recyclability and lower material waste during production. Aluminum monoblock's single-material structure simplifies recycling processes, reducing landfill contributions and energy consumption compared to the multilayer composition of aluminum laminate. The complex manufacturing and separation challenges of aluminum laminate often result in increased carbon emissions and resource inefficiencies, making aluminum monoblock a more eco-friendly choice in sustainable aluminum applications.

Aluminum Laminate vs Aluminum Monoblock Infographic

materialdif.com

materialdif.com