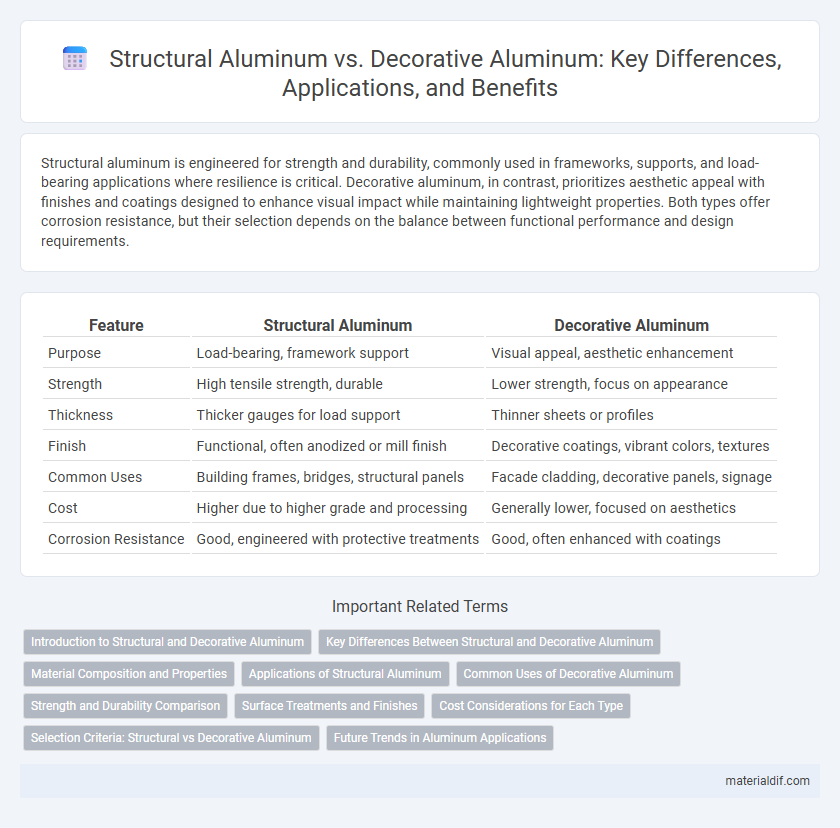

Structural aluminum is engineered for strength and durability, commonly used in frameworks, supports, and load-bearing applications where resilience is critical. Decorative aluminum, in contrast, prioritizes aesthetic appeal with finishes and coatings designed to enhance visual impact while maintaining lightweight properties. Both types offer corrosion resistance, but their selection depends on the balance between functional performance and design requirements.

Table of Comparison

| Feature | Structural Aluminum | Decorative Aluminum |

|---|---|---|

| Purpose | Load-bearing, framework support | Visual appeal, aesthetic enhancement |

| Strength | High tensile strength, durable | Lower strength, focus on appearance |

| Thickness | Thicker gauges for load support | Thinner sheets or profiles |

| Finish | Functional, often anodized or mill finish | Decorative coatings, vibrant colors, textures |

| Common Uses | Building frames, bridges, structural panels | Facade cladding, decorative panels, signage |

| Cost | Higher due to higher grade and processing | Generally lower, focused on aesthetics |

| Corrosion Resistance | Good, engineered with protective treatments | Good, often enhanced with coatings |

Introduction to Structural and Decorative Aluminum

Structural aluminum is engineered for strength, durability, and load-bearing applications in construction and manufacturing, ensuring stability and resistance to environmental stresses. Decorative aluminum prioritizes aesthetic appeal, featuring surface treatments such as anodizing, powder coating, and intricate finishes to enhance visual qualities while maintaining lightweight properties. Both types leverage aluminum's corrosion resistance and versatility but serve distinctly functional versus ornamental purposes.

Key Differences Between Structural and Decorative Aluminum

Structural aluminum is engineered for strength, durability, and load-bearing applications, commonly used in construction, transportation, and industrial frameworks. Decorative aluminum prioritizes aesthetics and surface finish, featuring anodized or painted coatings for enhanced visual appeal in architectural and design projects. Key differences lie in alloy composition, mechanical properties, and surface treatments tailored to either functional support or ornamental use.

Material Composition and Properties

Structural aluminum is primarily composed of high-strength alloys such as 6061 and 7075, which include elements like magnesium, silicon, and zinc to enhance tensile strength, corrosion resistance, and durability. Decorative aluminum typically uses softer alloys like 3003 and 5005, known for their excellent formability, surface finish, and corrosion resistance rather than load-bearing capabilities. The mechanical properties of structural aluminum feature higher yield strength and rigidity, while decorative aluminum emphasizes aesthetic qualities and ease of fabrication.

Applications of Structural Aluminum

Structural aluminum is widely used in construction and aerospace industries due to its high strength-to-weight ratio, corrosion resistance, and durability under stress. Common applications include building frameworks, bridges, aircraft components, and automotive parts where load-bearing capacity and reliability are critical. Its lightweight nature reduces overall structural weight, enhancing fuel efficiency and reducing transportation costs in various engineering projects.

Common Uses of Decorative Aluminum

Decorative aluminum is widely used in architectural facades, interior design elements, and signage due to its lightweight nature and excellent corrosion resistance. It often features anodized or powder-coated finishes to enhance aesthetic appeal and durability in applications such as wall cladding, ceiling panels, and decorative trims. Common uses also include furniture accents, lighting fixtures, and art installations where visual impact and design flexibility are priorities.

Strength and Durability Comparison

Structural aluminum exhibits superior strength and durability compared to decorative aluminum due to its higher-grade alloys and engineered design for load-bearing applications. While decorative aluminum prioritizes aesthetics and corrosion resistance, structural aluminum is formulated to withstand significant stress, impact, and environmental factors without compromising integrity. The enhanced tensile strength and fatigue resistance of structural aluminum make it ideal for construction and industrial use, whereas decorative aluminum is more suited for surface finishes and non-structural elements.

Surface Treatments and Finishes

Structural aluminum often undergoes anodizing and powder coating to enhance corrosion resistance and mechanical strength, ensuring durability in demanding applications. Decorative aluminum typically features polished, brushed, or painted finishes that prioritize aesthetic appeal while providing moderate protection against environmental factors. Both surface treatments improve aluminum's lifespan, but structural applications demand thicker, more functional coatings compared to the thinner, visually-focused finishes used in decorative contexts.

Cost Considerations for Each Type

Structural aluminum typically incurs higher costs due to its enhanced strength, durability, and compliance with safety standards, making it suitable for load-bearing applications. Decorative aluminum is generally more affordable, emphasizing aesthetic appeal and surface finishes without the need for stringent performance specifications. Cost considerations must balance the intended function, with structural aluminum demanding greater investment for reliability, while decorative aluminum offers budget-friendly options for non-structural uses.

Selection Criteria: Structural vs Decorative Aluminum

Selection criteria for structural aluminum prioritize strength, load-bearing capacity, and corrosion resistance to ensure safety and durability in construction applications. Decorative aluminum selection focuses on aesthetic appeal, surface finish, and ease of fabrication to enhance visual impact without compromising structural integrity. Understanding specific project requirements helps determine the optimal balance between mechanical properties and design elements.

Future Trends in Aluminum Applications

Structural aluminum continues to advance with innovations in high-strength alloys and lightweight composites, enabling its expanded use in aerospace, automotive, and construction industries due to its superior load-bearing capacity and corrosion resistance. Decorative aluminum is evolving through surface treatments such as anodizing, powder coating, and advanced printing technologies that offer enhanced aesthetic appeal and durability for architectural facades and interior design. Future trends emphasize sustainability and recyclability, integrating smart materials and multifunctional coatings that enhance both structural performance and decorative versatility in aluminum applications.

Structural Aluminum vs Decorative Aluminum Infographic

materialdif.com

materialdif.com