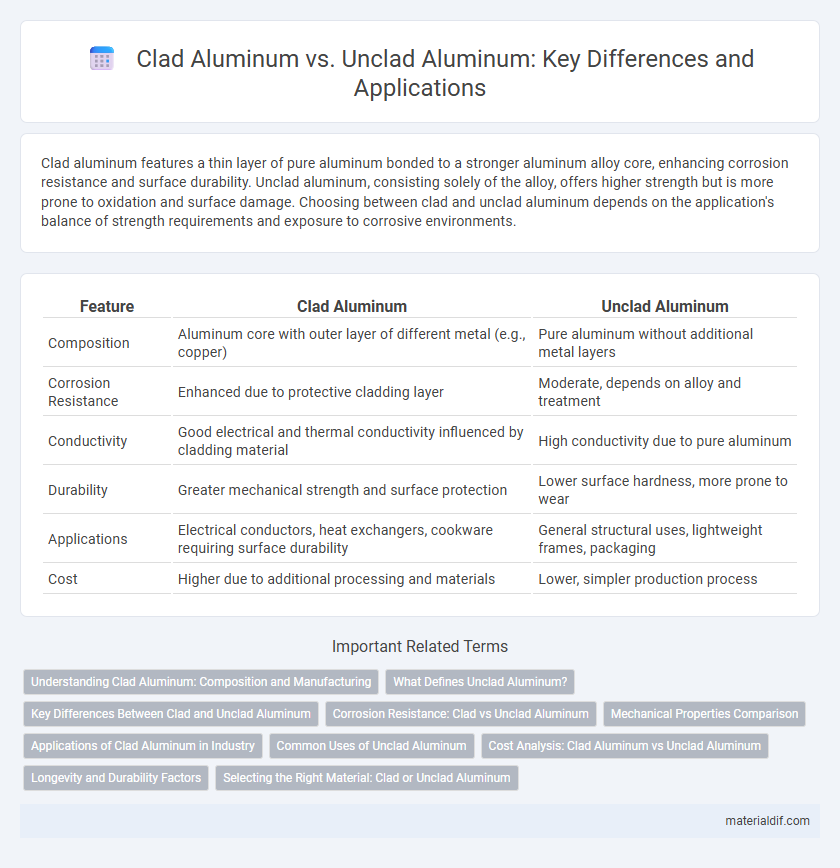

Clad aluminum features a thin layer of pure aluminum bonded to a stronger aluminum alloy core, enhancing corrosion resistance and surface durability. Unclad aluminum, consisting solely of the alloy, offers higher strength but is more prone to oxidation and surface damage. Choosing between clad and unclad aluminum depends on the application's balance of strength requirements and exposure to corrosive environments.

Table of Comparison

| Feature | Clad Aluminum | Unclad Aluminum |

|---|---|---|

| Composition | Aluminum core with outer layer of different metal (e.g., copper) | Pure aluminum without additional metal layers |

| Corrosion Resistance | Enhanced due to protective cladding layer | Moderate, depends on alloy and treatment |

| Conductivity | Good electrical and thermal conductivity influenced by cladding material | High conductivity due to pure aluminum |

| Durability | Greater mechanical strength and surface protection | Lower surface hardness, more prone to wear |

| Applications | Electrical conductors, heat exchangers, cookware requiring surface durability | General structural uses, lightweight frames, packaging |

| Cost | Higher due to additional processing and materials | Lower, simpler production process |

Understanding Clad Aluminum: Composition and Manufacturing

Clad aluminum consists of a core aluminum alloy bonded with a thin layer of high-purity aluminum or other metals, providing enhanced corrosion resistance and improved surface finish. The manufacturing process involves metallurgical bonding under heat and pressure, ensuring the integrity of the outer cladding while maintaining the mechanical properties of the core. This composition allows clad aluminum to combine strength and durability with a clean, corrosion-resistant surface ideal for applications in cookware, packaging, and architectural products.

What Defines Unclad Aluminum?

Unclad aluminum refers to aluminum metal that has not been coated or bonded with another metal layer, maintaining its pure aluminum surface. This type of aluminum exhibits natural oxidation on its surface, resulting in a thin, protective layer that enhances corrosion resistance without additional cladding. Unclad aluminum is favored in applications requiring direct conductivity and high reflectivity, such as electrical components and heat exchangers.

Key Differences Between Clad and Unclad Aluminum

Clad aluminum features a layer of pure aluminum bonded to an aluminum alloy core, enhancing corrosion resistance and improving surface appearance, while unclad aluminum consists solely of the alloy material without this protective layer. The cladding process significantly increases durability in outdoor and marine environments, making clad aluminum preferable for architectural and automotive applications. Unclad aluminum, being less resistant to corrosion, is often chosen for applications where strength and lightweight properties are prioritized over surface finish.

Corrosion Resistance: Clad vs Unclad Aluminum

Clad aluminum features a pure aluminum outer layer that provides superior corrosion resistance compared to unclad aluminum, which lacks this protective barrier. The cladding prevents exposure to harsh environmental elements, significantly reducing oxidation and pitting. Unclad aluminum, while lightweight and strong, is more susceptible to corrosion, particularly in marine or acidic conditions.

Mechanical Properties Comparison

Clad aluminum features an outer layer of pure aluminum bonded to an aluminum alloy core, enhancing corrosion resistance without compromising strength. Unclad aluminum consists solely of a uniform alloy, providing higher strength and stiffness but less surface protection. The mechanical properties of clad aluminum typically show improved durability and resistance to environmental degradation, while unclad aluminum offers superior tensile strength and hardness for structural applications.

Applications of Clad Aluminum in Industry

Clad aluminum combines a corrosion-resistant outer layer with a strong aluminum core, making it ideal for aerospace components, chemical processing equipment, and architectural panels where durability and resistance to environmental damage are critical. Its enhanced surface properties allow for improved welding, brazing, and joining in industrial manufacturing applications. The material's superior corrosion resistance and thermal performance enable long-lasting use in marine structures and heat exchangers.

Common Uses of Unclad Aluminum

Unclad aluminum is widely used in applications requiring excellent corrosion resistance and electrical conductivity, such as electrical transmission lines, aerospace components, and packaging materials. Its pure aluminum surface facilitates superior solderability and weldability, making it ideal for electrical and heat exchanger parts. Commonly employed in construction and transportation industries, unclad aluminum offers lightweight strength and durability without the cost of additional cladding layers.

Cost Analysis: Clad Aluminum vs Unclad Aluminum

Clad aluminum typically incurs higher initial costs due to the additional bonding process of pure aluminum layers onto the base alloy, which enhances corrosion resistance and surface finish. Unclad aluminum, made solely of the base alloy, is more cost-effective upfront but may require more frequent maintenance or replacement, increasing long-term expenses. Evaluating the total cost of ownership, clad aluminum often proves more economical in corrosive environments despite its higher purchase price.

Longevity and Durability Factors

Clad aluminum features a corrosion-resistant alloy layer bonded to a strong aluminum core, significantly enhancing its longevity and durability compared to unclad aluminum. Unclad aluminum, while lightweight and cost-effective, is more prone to oxidation and surface degradation over time, reducing its lifespan in harsh environments. The protective cladding in clad aluminum maintains structural integrity and appearance, making it ideal for applications requiring extended durability.

Selecting the Right Material: Clad or Unclad Aluminum

Clad aluminum features a corrosion-resistant layer bonded to a core of high-strength aluminum, making it ideal for cookware and applications requiring enhanced durability and food safety. Unclad aluminum offers superior heat conductivity due to its pure aluminum surface but lacks the protective layer, which can lead to faster oxidation and potential reactions with acidic foods. Selecting between clad and unclad aluminum depends on balancing performance needs such as corrosion resistance, heat transfer efficiency, and maintenance requirements.

Clad Aluminum vs Unclad Aluminum Infographic

materialdif.com

materialdif.com