Hot rolled aluminum undergoes processing at high temperatures, making it easier to shape and ideal for large structural applications due to its improved ductility. Cold rolled aluminum, processed at or near room temperature, offers superior surface finish and increased strength, making it suitable for precision components and aesthetic uses. Choosing between the two depends on the specific mechanical properties and surface quality required for aluminum pet manufacturing.

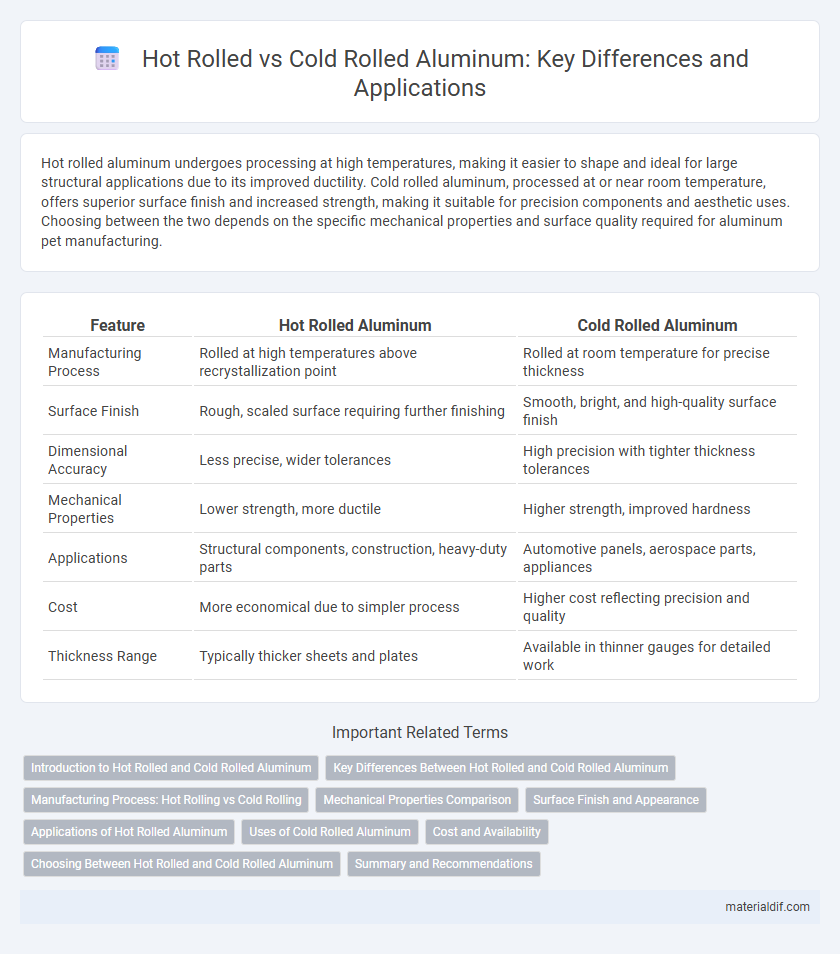

Table of Comparison

| Feature | Hot Rolled Aluminum | Cold Rolled Aluminum |

|---|---|---|

| Manufacturing Process | Rolled at high temperatures above recrystallization point | Rolled at room temperature for precise thickness |

| Surface Finish | Rough, scaled surface requiring further finishing | Smooth, bright, and high-quality surface finish |

| Dimensional Accuracy | Less precise, wider tolerances | High precision with tighter thickness tolerances |

| Mechanical Properties | Lower strength, more ductile | Higher strength, improved hardness |

| Applications | Structural components, construction, heavy-duty parts | Automotive panels, aerospace parts, appliances |

| Cost | More economical due to simpler process | Higher cost reflecting precision and quality |

| Thickness Range | Typically thicker sheets and plates | Available in thinner gauges for detailed work |

Introduction to Hot Rolled and Cold Rolled Aluminum

Hot rolled aluminum is processed at high temperatures above its recrystallization point, resulting in increased ductility and reduced residual stress, making it suitable for structural applications. Cold rolled aluminum undergoes further processing at room temperature, enhancing its surface finish and mechanical properties such as strength and hardness through strain hardening. Both methods impact the aluminum's grain structure differently, influencing its performance in various industrial uses.

Key Differences Between Hot Rolled and Cold Rolled Aluminum

Hot rolled aluminum is processed at high temperatures exceeding 400degC, resulting in a rougher surface finish and increased ductility, while cold rolled aluminum is rolled at room temperature, offering a smoother, more precise surface and improved mechanical properties such as higher strength and hardness. Hot rolling is ideal for large-scale structural applications due to its cost-effectiveness and ability to produce thicker sheets, whereas cold rolling is preferred for applications requiring tight tolerances, superior surface quality, and enhanced dimensional accuracy. The choice between hot rolled and cold rolled aluminum significantly impacts factors like tensile strength, surface texture, and manufacturing flexibility.

Manufacturing Process: Hot Rolling vs Cold Rolling

Hot rolled aluminum involves heating the metal above its recrystallization temperature before rolling, resulting in a product with improved ductility and reduced internal stresses, suitable for large structural applications. Cold rolled aluminum is processed at or near room temperature, which enhances surface finish, dimensional accuracy, and strength through strain hardening but requires subsequent annealing to restore ductility. The choice between hot rolling and cold rolling directly affects the aluminum's mechanical properties, surface quality, and suitability for various industrial uses.

Mechanical Properties Comparison

Hot rolled aluminum exhibits increased ductility and toughness due to its higher processing temperature, making it suitable for applications requiring greater formability and impact resistance. Cold rolled aluminum demonstrates superior strength and hardness achieved through strain hardening during room temperature processing, ideal for precision components needing enhanced dimensional accuracy and surface finish. Mechanical property data indicate hot rolled aluminum typically has tensile strength ranging from 150-300 MPa, while cold rolled aluminum can reach tensile strengths of 250-400 MPa, highlighting the trade-off between strength and ductility in different rolling processes.

Surface Finish and Appearance

Hot rolled aluminum exhibits a rougher surface finish characterized by mill scale and visible grain patterns, making it ideal for applications where surface aesthetics are less critical. Cold rolled aluminum undergoes further processing to produce a smoother, brighter surface with enhanced uniformity and minimal imperfections. The superior appearance of cold rolled aluminum is preferred for architectural and decorative purposes requiring a clean, polished look.

Applications of Hot Rolled Aluminum

Hot rolled aluminum is predominantly used in construction, automotive frames, and heavy machinery due to its enhanced ductility and ability to withstand structural stress. Its coarse surface finish and thicker gauge make it ideal for applications requiring strength over aesthetic precision, such as roofing panels, industrial containers, and bridges. The material's cost-effectiveness and high workability support manufacturing processes that involve large metal parts and fabrication with minimal finishing.

Uses of Cold Rolled Aluminum

Cold rolled aluminum is primarily used in applications requiring high strength, excellent surface finish, and precise dimensional tolerances, such as automotive panels, aerospace components, and electronic enclosures. Its superior mechanical properties and smooth surface make it ideal for decorative trim, furniture, and architectural applications where appearance is important. This material also offers enhanced corrosion resistance, making it suitable for indoor and outdoor use in various industrial and commercial products.

Cost and Availability

Hot rolled aluminum typically costs less than cold rolled aluminum due to its faster production process and lower energy consumption, making it more budget-friendly for large-scale projects. Cold rolled aluminum offers superior surface finish and tighter tolerances but comes at a higher price and is less readily available in bulk quantities. Availability of hot rolled aluminum tends to be greater, with more suppliers offering immediate stock compared to the more specialized cold rolled aluminum.

Choosing Between Hot Rolled and Cold Rolled Aluminum

Hot rolled aluminum offers improved ductility and is more cost-effective for applications requiring large thicknesses and less precise tolerances. Cold rolled aluminum provides a smoother surface finish, tighter dimensional tolerances, and enhanced strength, making it ideal for projects demanding high precision and aesthetic quality. Selecting between hot rolled and cold rolled aluminum depends on the specific requirements for mechanical properties, surface finish, and budget constraints.

Summary and Recommendations

Hot rolled aluminum exhibits a rougher surface finish and superior ductility, making it ideal for applications requiring shaping and forming such as automotive panels and structural components. Cold rolled aluminum offers enhanced strength, smooth surface, and tighter dimensional tolerances, suitable for precision parts, architectural facades, and electronic enclosures. For projects demanding high strength and aesthetic appeal, cold rolled aluminum is recommended, while hot rolled aluminum is preferable for cost-effective manufacturing requiring extensive machining or welding.

Hot Rolled Aluminum vs Cold Rolled Aluminum Infographic

materialdif.com

materialdif.com