Mirror finish aluminum offers a highly reflective, smooth surface that enhances aesthetic appeal and is ideal for decorative applications requiring a polished look. Brushed finish aluminum features a textured surface with fine lines, providing a modern, matte appearance that resists fingerprints and hides minor scratches effectively. Choosing between mirror and brushed finishes depends on the desired visual effect and maintenance preferences in various architectural, automotive, or consumer product designs.

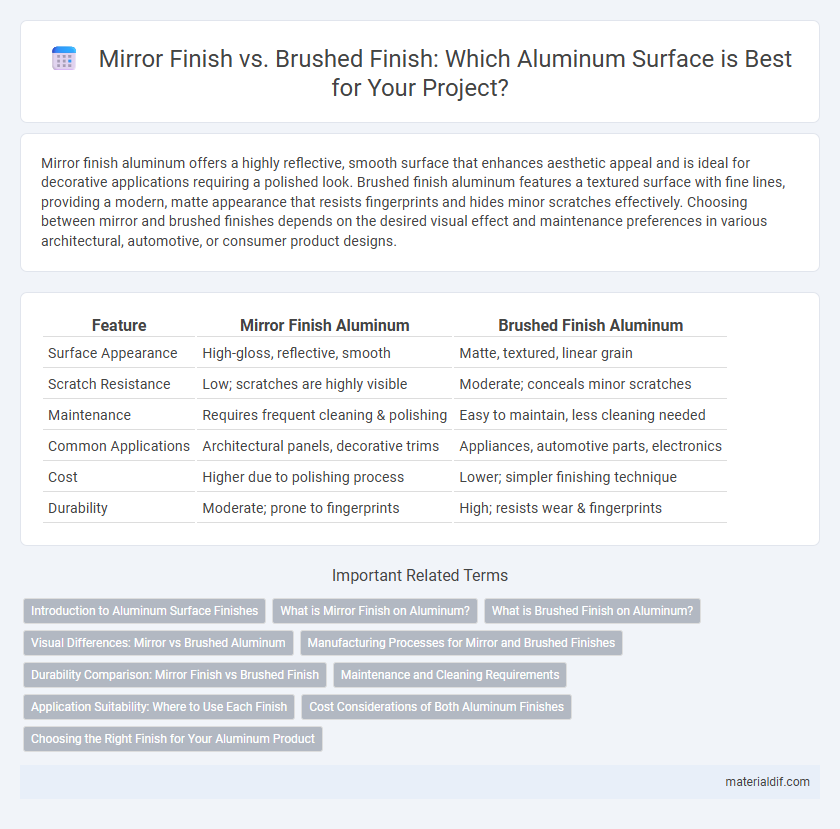

Table of Comparison

| Feature | Mirror Finish Aluminum | Brushed Finish Aluminum |

|---|---|---|

| Surface Appearance | High-gloss, reflective, smooth | Matte, textured, linear grain |

| Scratch Resistance | Low; scratches are highly visible | Moderate; conceals minor scratches |

| Maintenance | Requires frequent cleaning & polishing | Easy to maintain, less cleaning needed |

| Common Applications | Architectural panels, decorative trims | Appliances, automotive parts, electronics |

| Cost | Higher due to polishing process | Lower; simpler finishing technique |

| Durability | Moderate; prone to fingerprints | High; resists wear & fingerprints |

Introduction to Aluminum Surface Finishes

Aluminum surface finishes play a crucial role in enhancing both aesthetics and durability, with mirror and brushed finishes being two popular options. Mirror finish aluminum offers a highly reflective, smooth surface ideal for decorative applications requiring a sleek, polished look. Brushed finish aluminum features fine, directional lines created by abrasive brushing, providing a matte appearance that reduces glare and hides fingerprints while maintaining corrosion resistance.

What is Mirror Finish on Aluminum?

Mirror finish on aluminum is a highly polished surface treatment that creates a reflective, glass-like appearance by finely buffing and smoothing the metal. This finish enhances aluminum's aesthetic appeal and corrosion resistance, making it ideal for decorative applications and architectural elements. Achieving a mirror finish requires precise mechanical polishing and often involves multiple stages of abrasive and polishing compounds.

What is Brushed Finish on Aluminum?

Brushed finish on aluminum is a surface treatment that creates a textured, matte appearance by sanding the metal with a fine abrasive. This technique enhances the aluminum's durability, hides fingerprints and minor scratches, and offers a modern, industrial aesthetic. Compared to a mirror finish, brushed aluminum provides a non-reflective surface ideal for reducing glare in various applications.

Visual Differences: Mirror vs Brushed Aluminum

Mirror finish aluminum exhibits a highly reflective, glass-like surface that enhances brightness and creates clear, sharp reflections, making it ideal for decorative applications where visual impact is crucial. In contrast, brushed finish aluminum features a textured, matte appearance with fine parallel lines that diffuse light, reducing glare and providing a subdued, industrial aesthetic. The choice between mirror and brushed aluminum significantly affects the visual appeal and light interaction, influencing design choices in architecture, automotive, and consumer products.

Manufacturing Processes for Mirror and Brushed Finishes

Mirror finish aluminum is achieved through a multi-step polishing process involving fine abrasives and buffing compounds to create a highly reflective surface. Brushed finish aluminum is produced using abrasive brushes or pads that create uniform, linear scratches, giving the metal a textured, matte appearance. Both finishes require precision in manufacturing, with mirror finishes demanding more intensive polishing and quality control to eliminate imperfections.

Durability Comparison: Mirror Finish vs Brushed Finish

Mirror finish aluminum exhibits a smooth, reflective surface that is more prone to scratches and visible wear over time, reducing its durability in high-traffic or abrasive environments. Brushed finish aluminum, characterized by its textured, matte appearance, effectively conceals minor scratches and surface imperfections, enhancing longevity and resistance to wear in industrial and outdoor applications. For environments demanding sustained resistance to surface damage, brushed finish aluminum offers superior durability compared to mirror finish alternatives.

Maintenance and Cleaning Requirements

Mirror finish aluminum surfaces require frequent cleaning to maintain their high-gloss appearance, as fingerprints, smudges, and dust are more visible and can easily dull the shine. Brushed finish aluminum offers better concealment of scratches and fingerprints, reducing the need for constant cleaning and making it more practical for high-traffic or industrial environments. Both finishes benefit from non-abrasive cleaners and soft cloths to prevent surface damage during maintenance.

Application Suitability: Where to Use Each Finish

Mirror finish aluminum is ideal for decorative applications such as architectural facades, automotive trim, and household appliances where high reflectivity and a sleek, polished look are desired. Brushed finish aluminum excels in environments requiring durability and resistance to fingerprints and scratches, making it suitable for kitchen equipment, elevator panels, and electronic device casings. Choosing between mirror and brushed finishes depends on aesthetic requirements and the level of surface maintenance needed in the specific application.

Cost Considerations of Both Aluminum Finishes

Mirror finish aluminum generally incurs higher costs due to labor-intensive polishing processes and specialized equipment required to achieve a flawless reflective surface. Brushed finish aluminum offers a more budget-friendly alternative with simpler, faster production involving abrasive brushing that reduces labor and time expenses. Choosing between these finishes depends on balancing aesthetic preference with project budget constraints, as mirror finishes dramatically increase fabrication costs compared to brushed finishes.

Choosing the Right Finish for Your Aluminum Product

Choosing the right finish for your aluminum product depends on its intended use and aesthetic preference. Mirror finish aluminum offers a highly reflective, smooth surface ideal for decorative applications and environments requiring enhanced light reflection. Brushed finish provides a textured, matte appearance that better conceals scratches and fingerprints, making it suitable for functional items with frequent handling or exposure to wear.

Mirror Finish vs Brushed Finish Infographic

materialdif.com

materialdif.com