Aluminum bars feature flat, rectangular shapes ideal for structural applications requiring broad surface areas, while aluminum rods have a circular cross-section suited for machining and fastening purposes. Bars provide greater stability and are often used in frames or supports, whereas rods are preferred for shafts, pins, and axles due to their uniform diameter. Selecting between an aluminum bar and rod depends on the mechanical requirements and design specifications of the project.

Table of Comparison

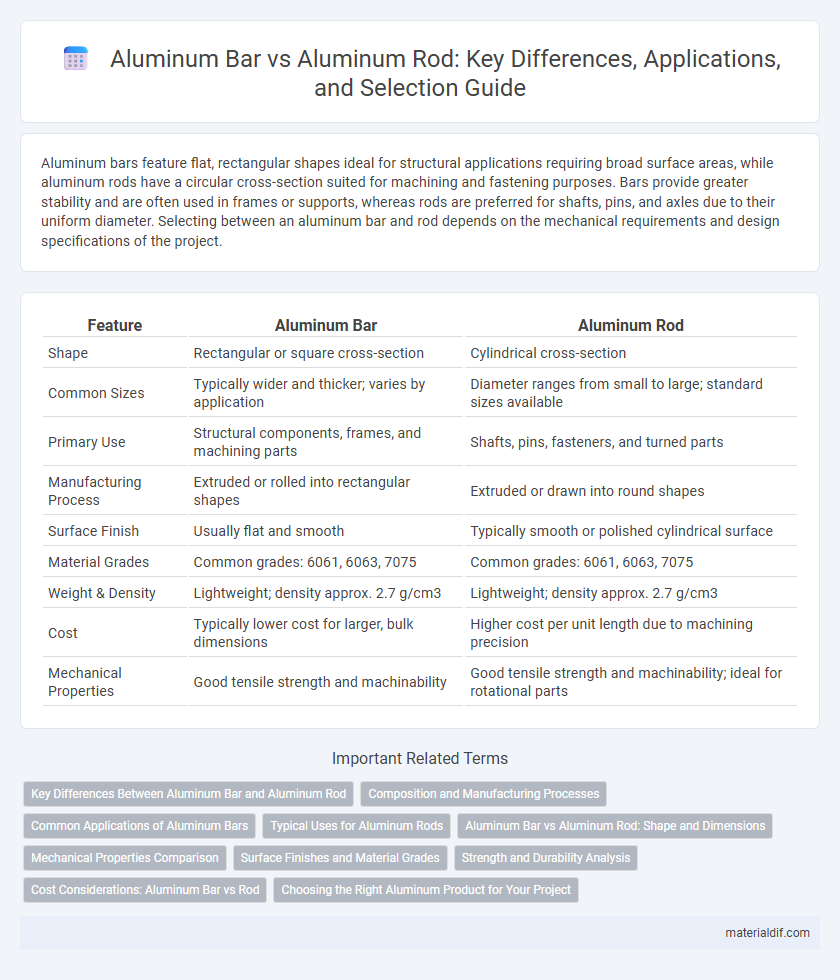

| Feature | Aluminum Bar | Aluminum Rod |

|---|---|---|

| Shape | Rectangular or square cross-section | Cylindrical cross-section |

| Common Sizes | Typically wider and thicker; varies by application | Diameter ranges from small to large; standard sizes available |

| Primary Use | Structural components, frames, and machining parts | Shafts, pins, fasteners, and turned parts |

| Manufacturing Process | Extruded or rolled into rectangular shapes | Extruded or drawn into round shapes |

| Surface Finish | Usually flat and smooth | Typically smooth or polished cylindrical surface |

| Material Grades | Common grades: 6061, 6063, 7075 | Common grades: 6061, 6063, 7075 |

| Weight & Density | Lightweight; density approx. 2.7 g/cm3 | Lightweight; density approx. 2.7 g/cm3 |

| Cost | Typically lower cost for larger, bulk dimensions | Higher cost per unit length due to machining precision |

| Mechanical Properties | Good tensile strength and machinability | Good tensile strength and machinability; ideal for rotational parts |

Key Differences Between Aluminum Bar and Aluminum Rod

Aluminum bars typically have a rectangular or square cross-section, while aluminum rods are usually cylindrical, making their shapes the primary distinguishing factor. Aluminum bars often offer greater surface area for fabrication and machining, suited for structural applications, whereas aluminum rods are preferred for shafts or pins due to their rounded form. The choice between aluminum bar and rod depends on strength requirements, machinability, and intended use in industries like aerospace, automotive, and construction.

Composition and Manufacturing Processes

Aluminum bars and rods primarily differ in their cross-sectional shapes, with bars typically having rectangular or square profiles, while rods are cylindrical. Both are composed mainly of aluminum alloys such as 6061 and 7075, selected for strength, corrosion resistance, and machinability. Manufacturing processes for bars often involve extrusion followed by rolling or machining, whereas rods are commonly produced through hot rolling, drawing, or extrusion to achieve precise diameters and surface finishes.

Common Applications of Aluminum Bars

Aluminum bars are widely used in structural frameworks, machinery components, and construction projects due to their flat surfaces and ease of machining. Common applications include manufacturing brackets, supports, and marine hardware where strength and corrosion resistance are critical. Their versatility in fabrication makes aluminum bars ideal for aerospace, automotive, and architectural industries.

Typical Uses for Aluminum Rods

Aluminum rods are commonly used in manufacturing processes that require precise machining, such as automotive components, aerospace parts, and electrical connectors. Their uniform diameter and superior tensile strength make them ideal for shafts, pins, and fasteners where durability is critical. Aluminum rods also serve in construction and marine applications due to their excellent corrosion resistance and lightweight properties.

Aluminum Bar vs Aluminum Rod: Shape and Dimensions

Aluminum bars typically feature a rectangular or square cross-section, making them ideal for structural applications requiring flat surfaces and precise edges, whereas aluminum rods are cylindrical, suited for machining and turning processes that benefit from round profiles. Dimensions of aluminum bars are often specified by width, height, and length, while aluminum rods are measured by diameter and length, reflecting their distinct manufacturing and usage standards. Shape and dimensional differences directly influence the selection of aluminum bars or rods based on the engineering requirements of strength, surface area, and machining versatility.

Mechanical Properties Comparison

Aluminum bars typically offer greater structural strength and stiffness compared to aluminum rods, due to their larger cross-sectional area and shape versatility. Mechanical properties such as tensile strength and yield strength tend to be higher in aluminum bars, making them suitable for heavy-duty applications. Aluminum rods, with their uniform circular cross-section, provide consistent mechanical performance and are often preferred in precision machining and lightweight structural components.

Surface Finishes and Material Grades

Aluminum bars typically feature a milled or extruded surface finish that offers smoothness suitable for machining and structural applications, while aluminum rods often have a turned or drawn finish providing enhanced surface uniformity ideal for precision components. Material grades for aluminum bars commonly include 6061 and 2024 alloys known for excellent strength-to-weight ratios and corrosion resistance, whereas aluminum rods frequently utilize 7075 and 5052 grades prized for superior hardness and ductility in aerospace and marine environments. Selection between bars and rods depends on the specific surface finish requirements and mechanical properties demanded by industrial standards and end-use applications.

Strength and Durability Analysis

Aluminum bars typically exhibit greater strength and durability compared to aluminum rods due to their wider surface area and solid cross-section, which provide enhanced load-bearing capacity and resistance to bending. The manufacturing process of bars often involves rigorous extrusion or rolling, resulting in a denser grain structure that improves toughness and wear resistance. In contrast, aluminum rods, being slim and cylindrical, are better suited for applications requiring flexibility but generally offer lower structural strength and durability in heavy-duty environments.

Cost Considerations: Aluminum Bar vs Rod

Aluminum bars generally cost less per pound compared to aluminum rods due to their simpler manufacturing process and wider availability in standard shapes like rectangular or square profiles. Aluminum rods often incur higher costs because they require more precise extrusion or forging techniques, especially when manufactured in round or custom diameters. When budgeting for projects, choosing aluminum bars can offer significant savings, particularly for applications requiring larger volumes or less complex geometries.

Choosing the Right Aluminum Product for Your Project

Aluminum bars provide a flat, rectangular cross-section ideal for structural applications requiring stability and ease of machining, while aluminum rods offer a round, uniform shape suitable for shafts, pins, and fasteners. Selection depends on project specifications such as load-bearing capacity, manufacturing processes, and required dimensions. Understanding the mechanical properties and form factors of each ensures optimal performance in aerospace, automotive, or construction uses.

Aluminum Bar vs Aluminum Rod Infographic

materialdif.com

materialdif.com