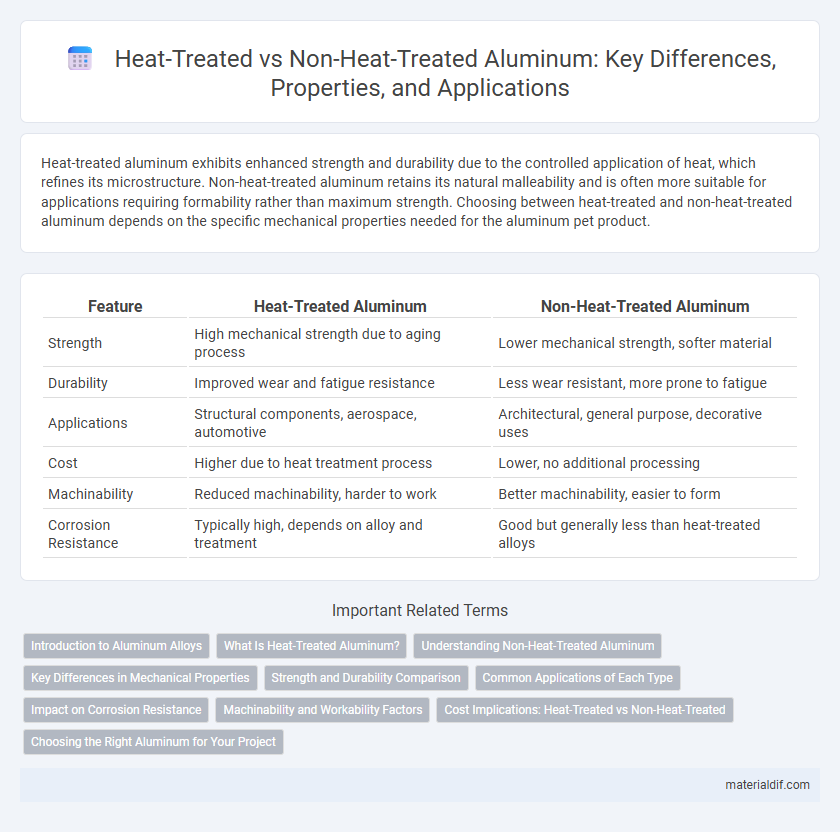

Heat-treated aluminum exhibits enhanced strength and durability due to the controlled application of heat, which refines its microstructure. Non-heat-treated aluminum retains its natural malleability and is often more suitable for applications requiring formability rather than maximum strength. Choosing between heat-treated and non-heat-treated aluminum depends on the specific mechanical properties needed for the aluminum pet product.

Table of Comparison

| Feature | Heat-Treated Aluminum | Non-Heat-Treated Aluminum |

|---|---|---|

| Strength | High mechanical strength due to aging process | Lower mechanical strength, softer material |

| Durability | Improved wear and fatigue resistance | Less wear resistant, more prone to fatigue |

| Applications | Structural components, aerospace, automotive | Architectural, general purpose, decorative uses |

| Cost | Higher due to heat treatment process | Lower, no additional processing |

| Machinability | Reduced machinability, harder to work | Better machinability, easier to form |

| Corrosion Resistance | Typically high, depends on alloy and treatment | Good but generally less than heat-treated alloys |

Introduction to Aluminum Alloys

Heat-treated aluminum alloys undergo processes such as solution heat treatment and aging to enhance mechanical properties like strength, hardness, and corrosion resistance, making them ideal for aerospace, automotive, and structural applications. Non-heat-treated aluminum alloys, often called work-hardened or annealed alloys, retain their original ductility and formability but exhibit lower tensile strength compared to their heat-treated counterparts. Understanding the distinctions between these alloys is critical for selecting the appropriate aluminum grade to meet specific engineering and performance requirements.

What Is Heat-Treated Aluminum?

Heat-treated aluminum undergoes a thermal process called solution heat treatment, where the alloy is heated to high temperatures and rapidly cooled to enhance its mechanical properties such as strength and hardness. This treatment modifies the microstructure by dissolving alloying elements, enabling precipitation hardening that significantly improves performance in structural applications. Non-heat-treated aluminum retains its original annealed state, resulting in lower strength and less resistance to wear compared to its heat-treated counterparts.

Understanding Non-Heat-Treated Aluminum

Non-heat-treated aluminum, also known as annealed aluminum, retains its natural softness and ductility, making it ideal for applications requiring easy forming and bending. This type of aluminum exhibits lower tensile strength and hardness compared to heat-treated variants but offers enhanced corrosion resistance in certain environments. Understanding the mechanical limitations and advantages of non-heat-treated aluminum is critical for selecting the appropriate grade in manufacturing and construction projects.

Key Differences in Mechanical Properties

Heat-treated aluminum exhibits significantly enhanced mechanical properties such as increased tensile strength, hardness, and fatigue resistance compared to non-heat-treated aluminum, owing to the precipitation hardening process that refines the microstructure. Non-heat-treated aluminum typically shows higher ductility and better corrosion resistance but lacks the strength and wear resistance required for high-stress applications. The selection between heat-treated and non-heat-treated aluminum depends on the specific mechanical performance demands of industries like aerospace, automotive, and construction.

Strength and Durability Comparison

Heat-treated aluminum alloys exhibit significantly higher tensile strength and improved durability compared to non-heat-treated aluminum due to the precipitation hardening process. Non-heat-treated aluminum generally maintains greater ductility but lacks the enhanced mechanical properties found in heat-treated variants, making it less suitable for high-stress applications. The heat treatment process optimizes the microstructure, resulting in superior resistance to wear, fatigue, and deformation under load.

Common Applications of Each Type

Heat-treated aluminum is commonly used in aerospace, automotive, and structural applications where enhanced strength and durability are critical, such as aircraft frames and high-performance vehicle parts. Non-heat-treated aluminum finds applications in construction, packaging, and everyday consumer products, including window frames, beverage cans, and household utensils, where flexibility and corrosion resistance are prioritized. Selecting the appropriate aluminum type depends on the specific mechanical properties required for the intended use.

Impact on Corrosion Resistance

Heat-treated aluminum undergoes processes such as solution heat treatment and aging that refine its microstructure, significantly enhancing corrosion resistance by forming a more stable and uniform oxide layer. In contrast, non-heat-treated aluminum retains a less homogenized grain structure, which can lead to localized corrosion and reduced durability in aggressive environments. The improved corrosion resistance of heat-treated aluminum makes it highly suitable for aerospace, marine, and automotive applications where material longevity and structural integrity are critical.

Machinability and Workability Factors

Heat-treated aluminum exhibits enhanced machinability due to increased hardness and strength, allowing for precise cutting and shaping with minimal tool wear. In contrast, non-heat-treated aluminum offers superior workability, featuring greater ductility and malleability that facilitate easier forming, bending, and welding. Selecting between heat-treated or non-heat-treated aluminum depends on the specific machining processes and the balance required between strength and ease of fabrication.

Cost Implications: Heat-Treated vs Non-Heat-Treated

Heat-treated aluminum incurs higher production costs due to the additional processes of solution heat treating and aging, which enhance its strength and durability. Non-heat-treated aluminum is more cost-effective but offers lower mechanical properties, limiting its application in high-stress environments. Choosing between the two depends on balancing budget constraints with performance requirements in specific industrial applications.

Choosing the Right Aluminum for Your Project

Heat-treated aluminum exhibits enhanced strength and durability due to processes like solution heat treatment and aging, making it ideal for structural applications and high-stress environments. Non-heat-treated aluminum offers greater malleability and corrosion resistance, suitable for intricate designs and lightweight projects. Selecting between heat-treated and non-heat-treated aluminum depends on criteria such as mechanical strength requirements, corrosion exposure, and fabrication methods for optimal performance.

Heat-Treated Aluminum vs Non-Heat-Treated Aluminum Infographic

materialdif.com

materialdif.com