Cold-worked aluminum exhibits increased strength and hardness due to strain hardening, making it ideal for applications requiring high durability and precision finishes. Hot-worked aluminum undergoes deformation at elevated temperatures, enhancing its ductility and reducing residual stresses for easier shaping and improved formability. Choosing between cold-worked and hot-worked aluminum depends on the desired mechanical properties and the specific manufacturing process requirements.

Table of Comparison

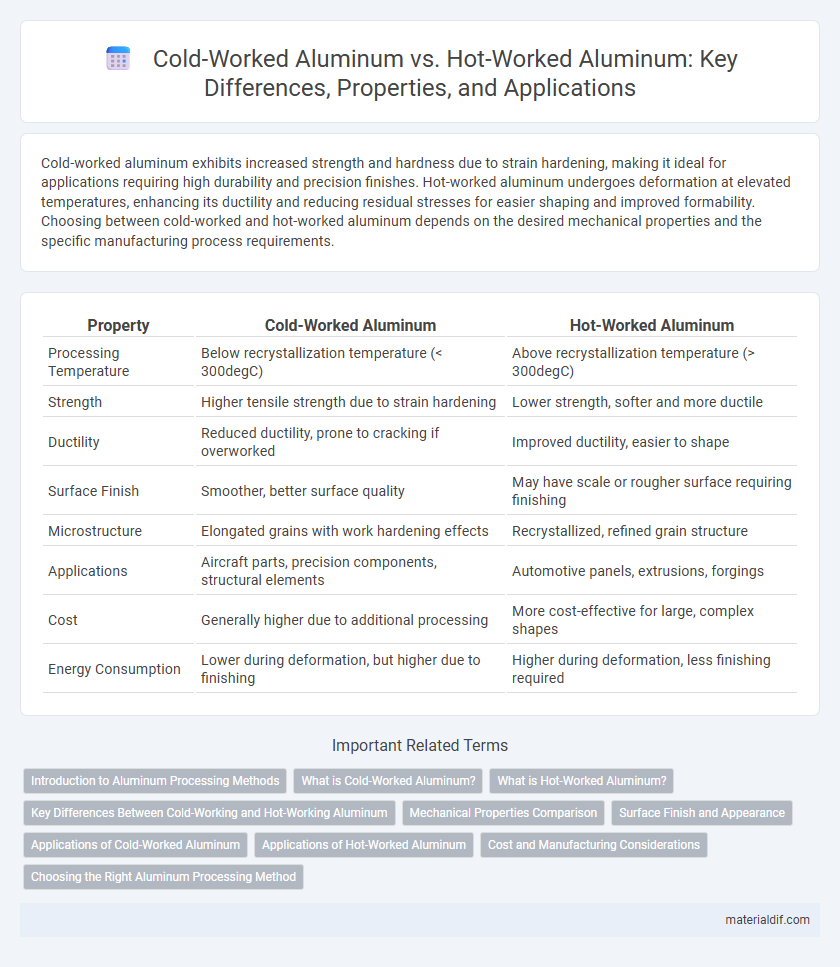

| Property | Cold-Worked Aluminum | Hot-Worked Aluminum |

|---|---|---|

| Processing Temperature | Below recrystallization temperature (< 300degC) | Above recrystallization temperature (> 300degC) |

| Strength | Higher tensile strength due to strain hardening | Lower strength, softer and more ductile |

| Ductility | Reduced ductility, prone to cracking if overworked | Improved ductility, easier to shape |

| Surface Finish | Smoother, better surface quality | May have scale or rougher surface requiring finishing |

| Microstructure | Elongated grains with work hardening effects | Recrystallized, refined grain structure |

| Applications | Aircraft parts, precision components, structural elements | Automotive panels, extrusions, forgings |

| Cost | Generally higher due to additional processing | More cost-effective for large, complex shapes |

| Energy Consumption | Lower during deformation, but higher due to finishing | Higher during deformation, less finishing required |

Introduction to Aluminum Processing Methods

Cold-worked aluminum undergoes plastic deformation at or near room temperature, which increases its strength and hardness through strain hardening while maintaining precise dimensional tolerances and a smooth surface finish. Hot-worked aluminum is processed above its recrystallization temperature, allowing for easier shaping and forming with reduced risk of cracking, resulting in improved ductility and grain structure refinement. These distinct aluminum processing methods optimize the metal's mechanical properties for varied industrial applications such as aerospace, automotive, and construction.

What is Cold-Worked Aluminum?

Cold-worked aluminum refers to aluminum that has been shaped or deformed at room temperature through processes like rolling, bending, or drawing without applying heat. This method increases the metal's strength and hardness by inducing strain hardening, but it may reduce its ductility. Common applications of cold-worked aluminum include structural components and electrical conductors where enhanced mechanical properties are critical.

What is Hot-Worked Aluminum?

Hot-worked aluminum refers to aluminum that has been deformed at elevated temperatures above its recrystallization point, typically between 300degC and 500degC, allowing for easier shaping and improved ductility. This process refines the grain structure, reduces internal stresses, and enhances mechanical properties such as toughness and machinability. Hot-working methods include forging, rolling, and extrusion, which enable the production of complex shapes and components used in aerospace, automotive, and construction industries.

Key Differences Between Cold-Working and Hot-Working Aluminum

Cold-worked aluminum undergoes deformation below its recrystallization temperature, resulting in increased strength and hardness through strain hardening, but with reduced ductility. Hot-worked aluminum is shaped above its recrystallization temperature, allowing for easier deformation with enhanced ductility and reduced residual stresses, promoting better formability. Key differences include the impact on mechanical properties, workability, and surface finish, with cold-working producing a harder, stronger alloy and hot-working enabling larger complex shapes with improved material uniformity.

Mechanical Properties Comparison

Cold-worked aluminum exhibits higher tensile strength and improved hardness due to strain hardening compared to hot-worked aluminum. Hot-worked aluminum, processed at elevated temperatures, shows better ductility and toughness but lower yield strength. The choice between cold- and hot-working significantly affects deformation resistance and mechanical performance in aluminum alloys.

Surface Finish and Appearance

Cold-worked aluminum exhibits a smoother, more polished surface finish with tighter dimensional tolerances compared to hot-worked aluminum. The hot-working process typically results in a rougher, more oxidized surface due to higher temperatures, requiring additional finishing treatments for aesthetic applications. Consequently, cold-worked aluminum is preferred in industries where superior surface appearance and fine detail are critical, such as aerospace and consumer electronics.

Applications of Cold-Worked Aluminum

Cold-worked aluminum exhibits increased strength and hardness compared to its hot-worked counterpart, making it ideal for structural components in aerospace and automotive industries. Its enhanced surface finish and dimensional accuracy benefit applications such as architectural fittings and consumer electronics. The strain-hardening process also improves fatigue resistance, essential for manufacturing load-bearing parts and precision instruments.

Applications of Hot-Worked Aluminum

Hot-worked aluminum is widely used in applications requiring complex shapes and improved mechanical properties, such as aerospace components, automotive frames, and shipbuilding structures. The elevated temperatures during hot working enable enhanced ductility and reduced internal stresses, making it suitable for large, intricate parts that undergo further machining or welding. Its ability to maintain strength and corrosion resistance under thermal exposure expands its use in industrial machinery and heavy equipment manufacturing.

Cost and Manufacturing Considerations

Cold-worked aluminum offers lower initial tooling costs and improved surface finish but requires more energy for deformation, increasing overall manufacturing expenses compared to hot-worked aluminum. Hot-working aluminum reduces material stress and allows for more complex shapes, leading to lower production costs in large-scale manufacturing due to faster processing times and decreased tool wear. Choosing between cold-worked and hot-worked aluminum depends on the balance of dimensional accuracy, surface requirements, and volume-driven cost efficiency in manufacturing.

Choosing the Right Aluminum Processing Method

Cold-worked aluminum exhibits higher strength and improved surface finish due to strain hardening, making it ideal for applications where precision and durability are critical, such as aerospace and automotive components. Hot-worked aluminum offers enhanced ductility and reduced residual stresses, facilitating complex shapes and large structural parts in construction and heavy machinery. Selecting the right aluminum processing method depends on balancing mechanical properties, formability, and end-use requirements to achieve optimal performance and cost-efficiency.

Cold-Worked Aluminum vs Hot-Worked Aluminum Infographic

materialdif.com

materialdif.com