Die casting aluminum offers superior precision and surface finish compared to sand casting aluminum, making it ideal for complex, high-volume parts with tighter tolerances. Sand casting aluminum provides greater design flexibility and lower tooling costs, suitable for larger components or smaller production runs. Choosing between die casting and sand casting depends on factors such as production volume, part complexity, and budget constraints.

Table of Comparison

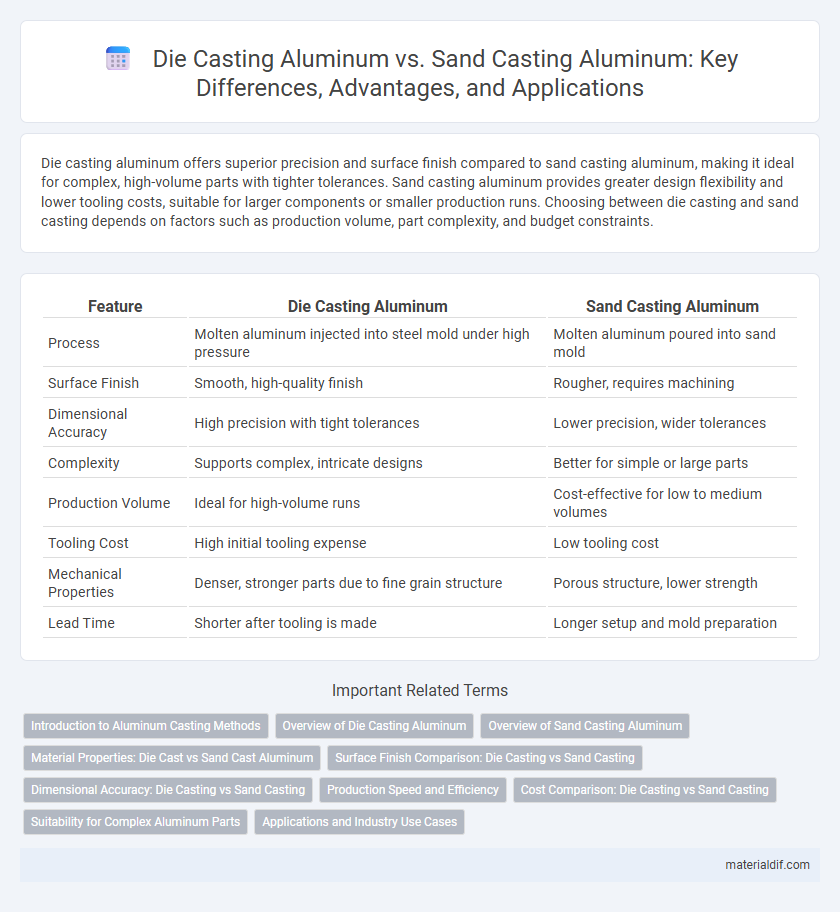

| Feature | Die Casting Aluminum | Sand Casting Aluminum |

|---|---|---|

| Process | Molten aluminum injected into steel mold under high pressure | Molten aluminum poured into sand mold |

| Surface Finish | Smooth, high-quality finish | Rougher, requires machining |

| Dimensional Accuracy | High precision with tight tolerances | Lower precision, wider tolerances |

| Complexity | Supports complex, intricate designs | Better for simple or large parts |

| Production Volume | Ideal for high-volume runs | Cost-effective for low to medium volumes |

| Tooling Cost | High initial tooling expense | Low tooling cost |

| Mechanical Properties | Denser, stronger parts due to fine grain structure | Porous structure, lower strength |

| Lead Time | Shorter after tooling is made | Longer setup and mold preparation |

Introduction to Aluminum Casting Methods

Die casting aluminum offers high precision and smooth surface finishes by forcing molten metal under high pressure into steel molds, making it ideal for complex, thin-walled components. Sand casting aluminum involves pouring molten metal into a sand mold, which is more versatile for large, intricate shapes but results in a rougher surface and less dimensional accuracy. Choosing between die casting and sand casting depends on factors like production volume, design complexity, and cost efficiency in aluminum component manufacturing.

Overview of Die Casting Aluminum

Die casting aluminum involves injecting molten aluminum into a steel mold under high pressure, producing precise, intricate, and high-strength components with excellent surface finish. This process offers faster production rates and tighter tolerances compared to sand casting, making it ideal for automotive, aerospace, and electronics industries. Die casting aluminum typically results in parts with superior mechanical properties and reduced need for secondary machining or finishing.

Overview of Sand Casting Aluminum

Sand casting aluminum involves pouring molten aluminum into a sand mold to create complex and large parts with varied geometries. This process offers lower tooling costs and greater design flexibility compared to die casting, making it ideal for small production runs or prototypes. Sand casting aluminum also allows for thicker walls and larger components but typically results in a rougher surface finish and less dimensional accuracy than die casting.

Material Properties: Die Cast vs Sand Cast Aluminum

Die cast aluminum typically exhibits superior dimensional accuracy and a smoother surface finish compared to sand cast aluminum, which often has a rougher texture and less precise tolerances. The microstructure of die cast aluminum is denser due to rapid cooling in a metal mold, resulting in enhanced mechanical properties such as higher tensile strength and better fatigue resistance. Sand cast aluminum offers greater design flexibility and thicker sections but generally shows lower strength and increased porosity compared to die cast components.

Surface Finish Comparison: Die Casting vs Sand Casting

Die casting aluminum offers a superior surface finish compared to sand casting aluminum, producing smoother and more precise details with minimal post-processing required. Sand casting aluminum typically results in a rougher texture due to the granular nature of the sand mold, often necessitating additional machining and finishing steps. The enhanced surface quality of die cast aluminum makes it ideal for applications demanding tight tolerances and aesthetically appealing components.

Dimensional Accuracy: Die Casting vs Sand Casting

Die casting aluminum offers superior dimensional accuracy compared to sand casting due to its high-pressure injection process, which produces parts with tighter tolerances and smoother surface finishes. Sand casting aluminum typically experiences greater dimensional variability because the mold material is less stable and prone to deformation during the cooling phase. In applications demanding precise, repeatable dimensions, die casting is preferred for its ability to consistently meet stringent specifications and reduce post-processing.

Production Speed and Efficiency

Die casting aluminum offers significantly faster production speeds compared to sand casting due to its use of reusable steel molds that enable rapid cooling and solidification cycles. This method ensures high efficiency with consistent dimensional accuracy and reduced post-processing time, making it ideal for high-volume manufacturing. Conversely, sand casting aluminum involves slower mold preparation and cooling times, resulting in longer production cycles and lower overall efficiency.

Cost Comparison: Die Casting vs Sand Casting

Die casting aluminum typically incurs higher initial tooling costs due to complex mold creation but offers lower per-unit expenses in large production runs, making it cost-effective for high-volume manufacturing. Sand casting aluminum involves lower upfront investment with reusable molds, making it suitable for small batches or prototypes despite higher per-unit costs and longer production times. Overall, die casting is economically advantageous for mass production, while sand casting remains a budget-friendly choice for limited quantities or custom parts.

Suitability for Complex Aluminum Parts

Die casting aluminum offers superior precision and intricate detail for complex aluminum parts due to its high-pressure injection process, resulting in tight tolerances and smooth surface finishes. Sand casting aluminum, while more cost-effective for larger, less detailed components, is less suitable for intricate geometries because of its coarser surface texture and lower dimensional accuracy. Industries requiring complex and high-strength aluminum parts, such as aerospace and automotive, predominantly favor die casting over sand casting for enhanced performance and reliability.

Applications and Industry Use Cases

Die casting aluminum is preferred in automotive and aerospace industries due to its high precision, smooth surface finish, and ability to produce complex geometries, making it ideal for engine components, housings, and structural parts. Sand casting aluminum is widely used in heavy machinery, construction, and marine applications where larger, less intricate parts such as pumps, valve bodies, and engine blocks are required, due to its cost-effectiveness and flexibility for low-volume production. The choice between die casting and sand casting depends on factors like production volume, part complexity, mechanical properties, and surface finish requirements.

Die Casting Aluminum vs Sand Casting Aluminum Infographic

materialdif.com

materialdif.com